Mask, method of manufacturing mask, device for manufacturing mask, method of manufacturing layer of luminescent material

A manufacturing method and mask technology, which are applied in the fields of original components for photomechanical processing, semiconductor/solid-state device manufacturing, optics, etc., can solve the problems of platform device complexity, mask temperature rise, position deviation, etc., and achieve suppression of masking. Effect of film failure, warping or warpage suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of a mask manufacturing method, a mask manufacturing apparatus, a light emitting material film forming method, an electro-optical device, and an electronic device according to the present invention will be described with reference to the drawings.

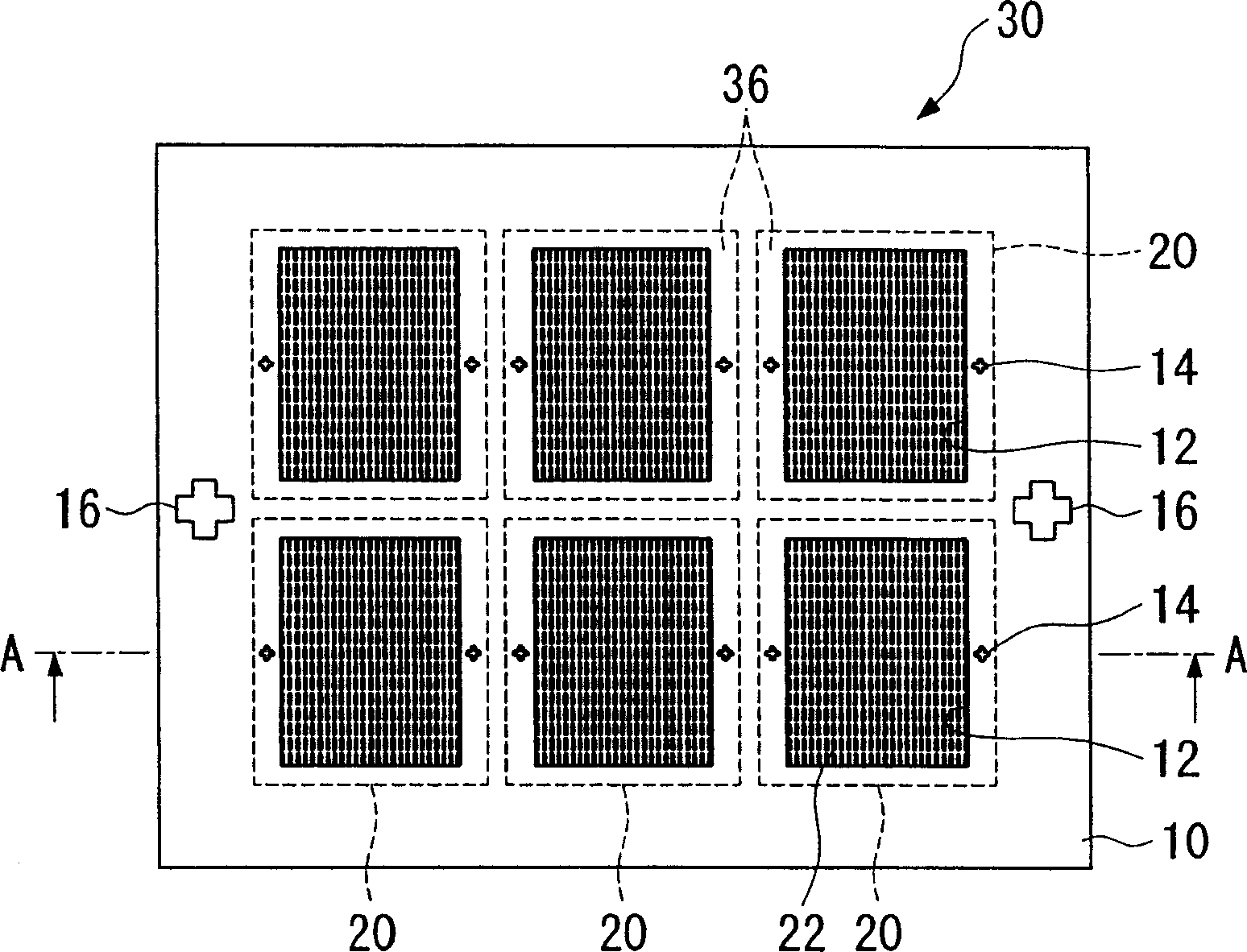

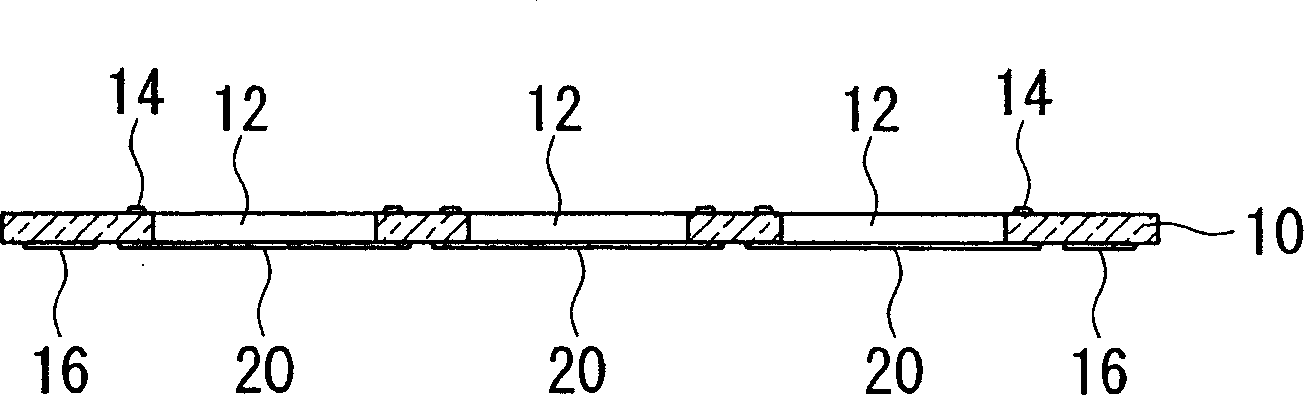

[0046] Figure 1A and Figure 1B is a diagram showing the mask 30 . Figure 1B yes Figure 1A The A-A line profile in.

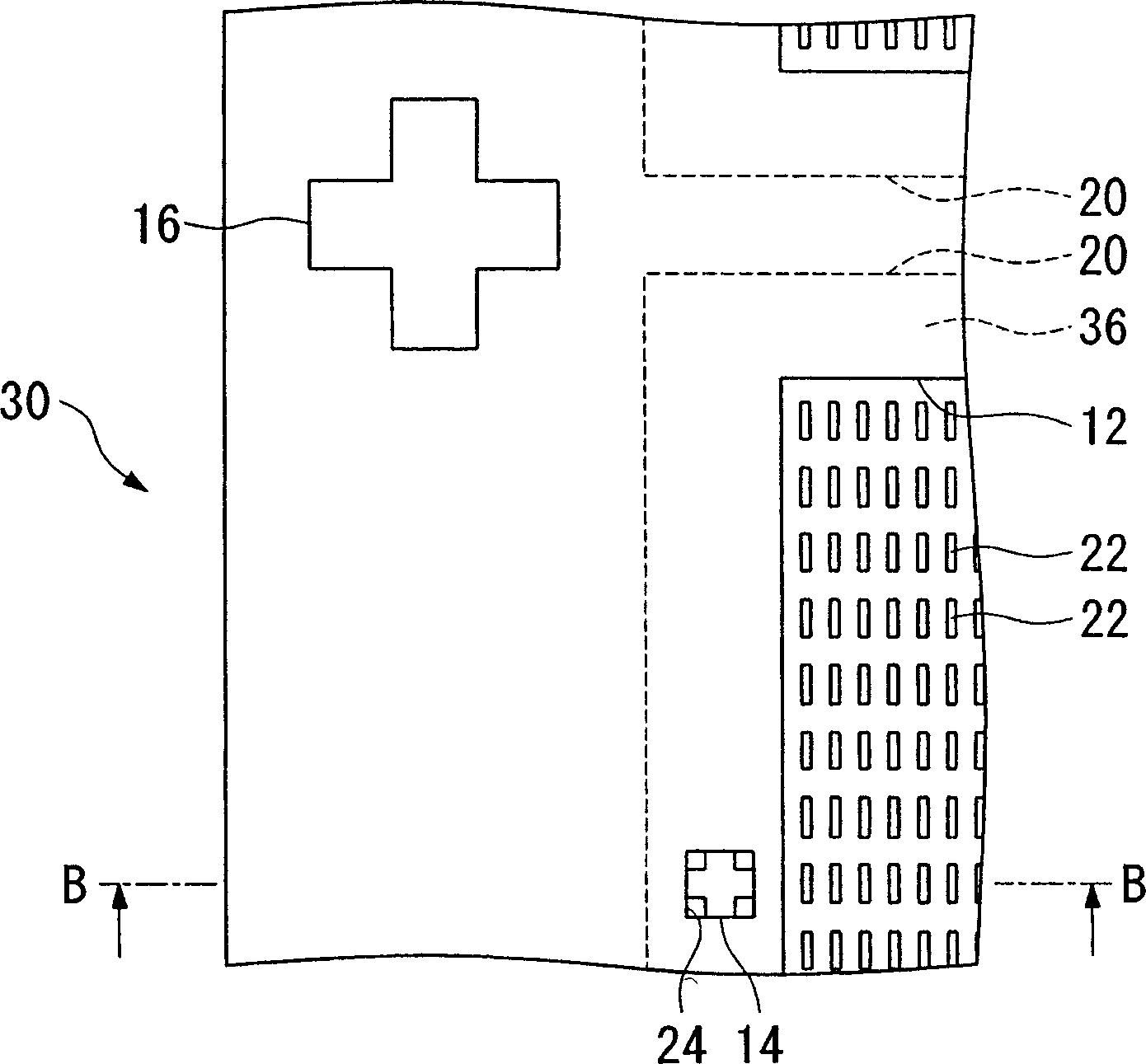

[0047] Figure 2A and Figure 2B It is an enlarged view showing the bonding region 36 of the mask 30 . Figure 2B yes Figure 2A B-B line profile.

[0048] The mask 30 used in the embodiment of the present invention is composed of a base material 10 and six mask members. Six openings 12 are formed in the base material 10 , corresponding to one opening 12 , and one mask member 20 is arranged so as to cover the opening 12 . That is, the region where the end portion of the mask member 20 overlaps with the end portion of the opening 12 of the base material 10 is used as the bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com