Electric fork track lifting control system possessing energy recovery device

An electric forklift and energy recovery technology, applied in the direction of hoisting device, can solve the problems of insufficient use of motor power, low operating efficiency of hydraulic system, and improvement in efficiency, so as to achieve high-efficiency control, improve operating efficiency, and improve The effect of using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

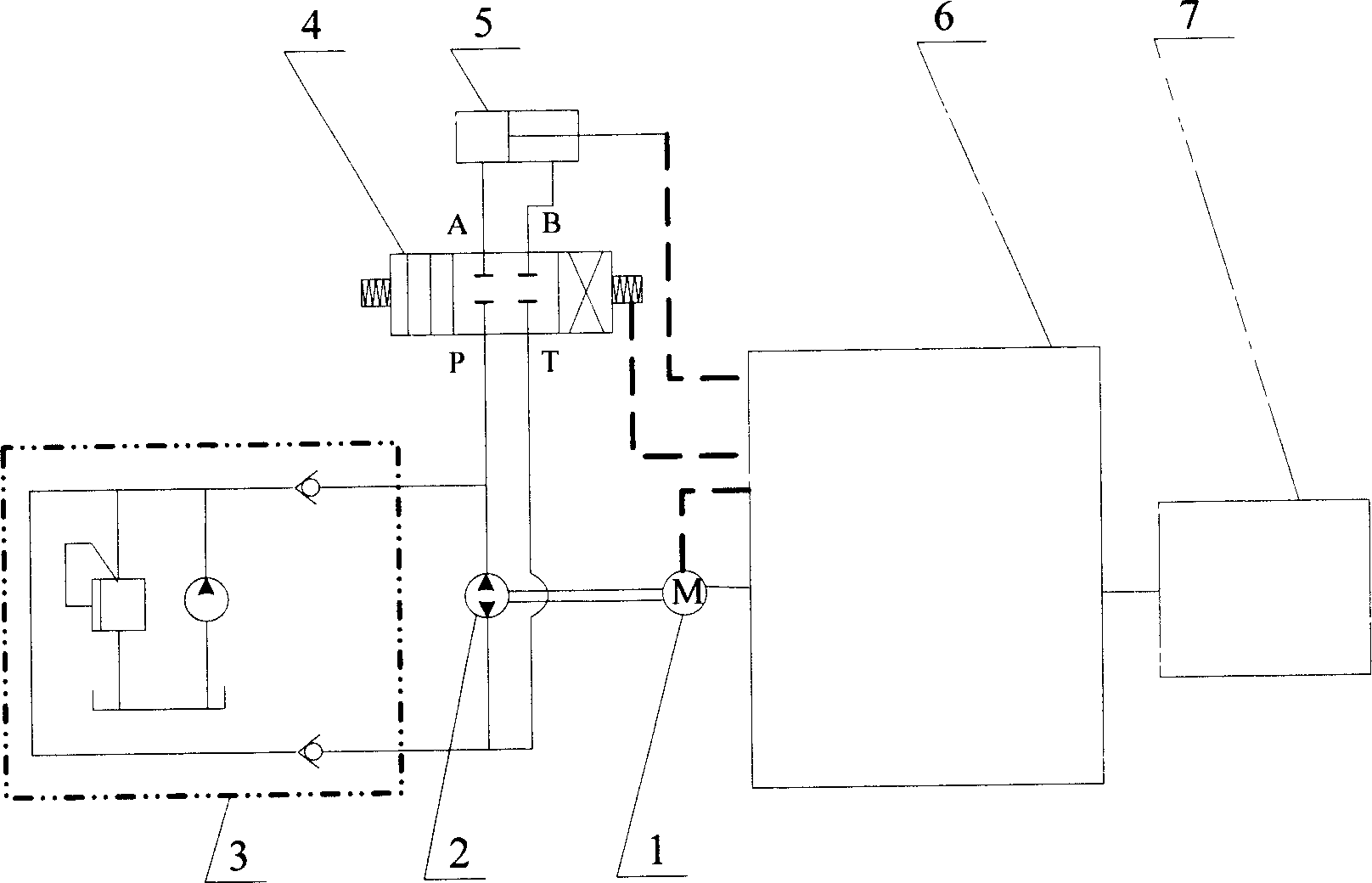

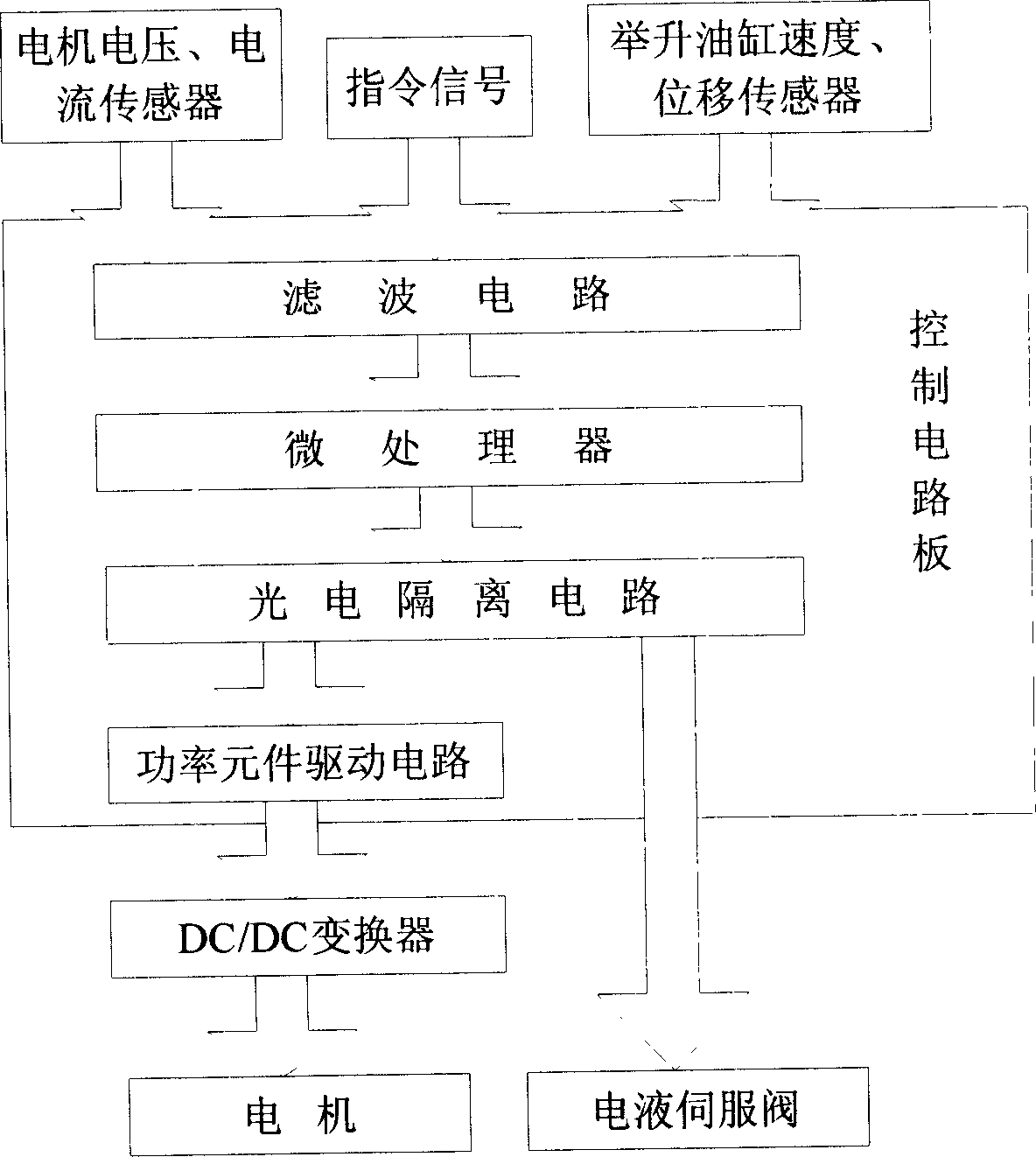

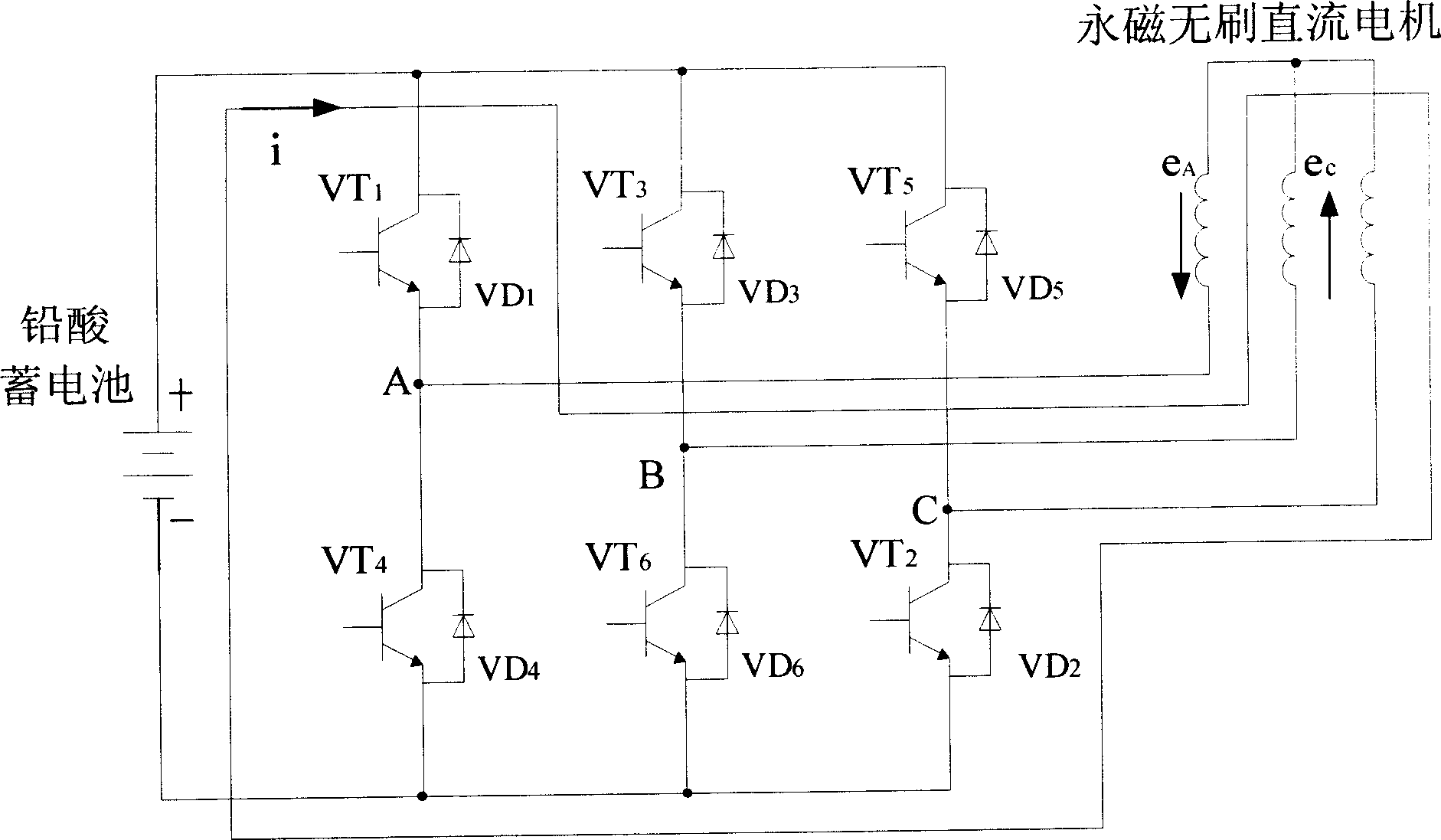

[0016] The invention includes a permanent magnet brushless DC motor 1, a pump-motor 2, an oil supply device 3, an electro-hydraulic servo valve 4, a lifting oil cylinder 5, a control device 6, and a lead-acid storage battery 7. Its interconnection relationship is as follows:

[0017] 1) The permanent magnet brushless DC motor 1 is connected to the pump-motor 2 whose displacement is equivalent to the area of the two cavities of the lifting cylinder.

[0018] 2) The P port and the T port of the electro-hydraulic servo valve 4 are respectively connected with the oil discharge port and the oil suction port of the pump-motor 2, and the A port and the B port of the electro-hydraulic servo valve 4 are connected with the rodless chamber and the lift cylinder 5 respectively. There are rod cavities connected. The oil supply device 3 is connected to the oil discharge port and the oil suction port of the pump-motor 2, and is connected to the P port and the T port of the electro-hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com