Method of producing mountain spring water using natural multiple filtering technology

A mountain spring water and process technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, adsorption water/sewage treatment, etc., can solve problems such as effective guarantee, inability to remove, difficult water quality safety, etc., to prolong service life, The effect of reducing production costs and reducing pollution levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

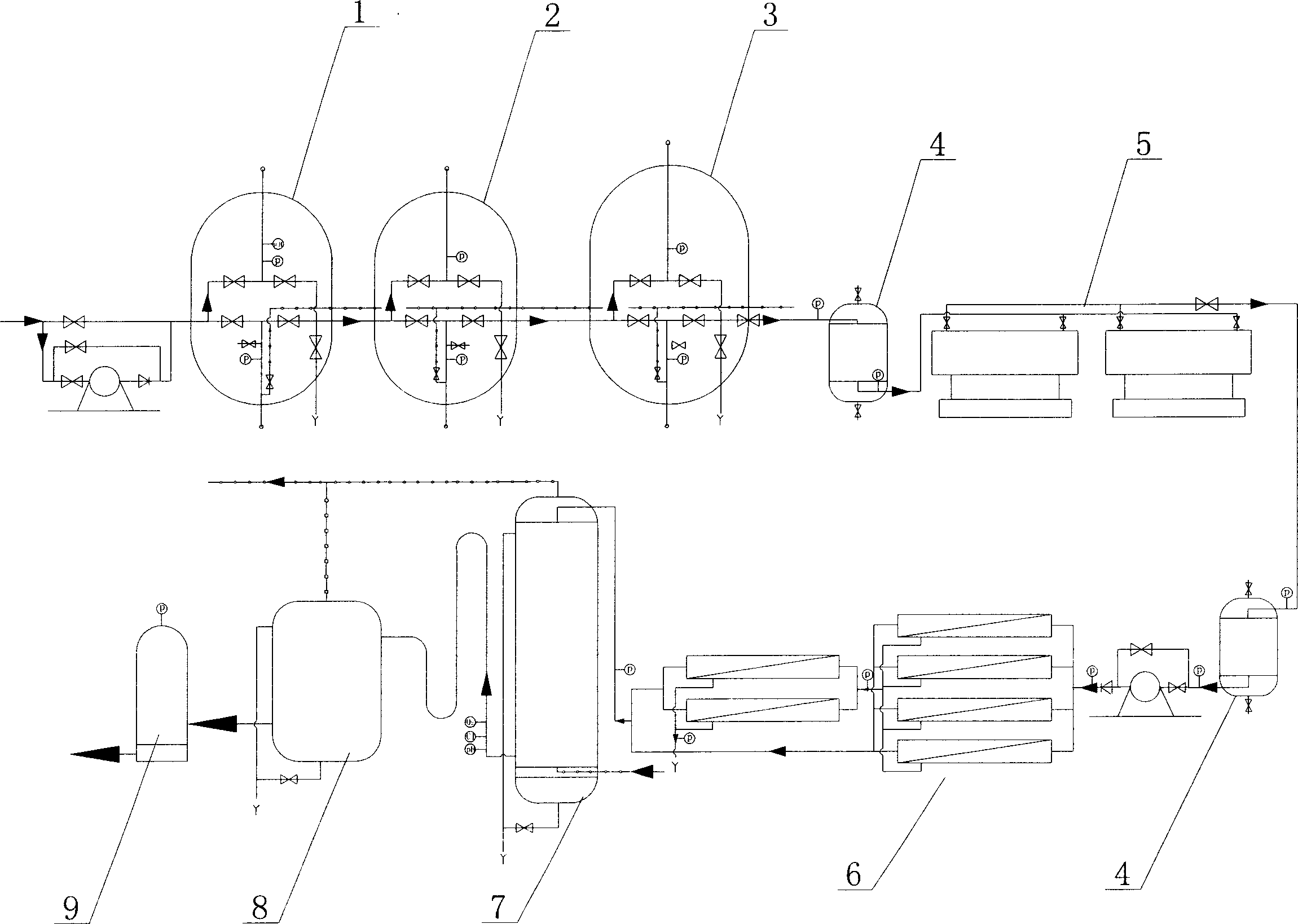

[0019] Such as figure 1 Shown, the present invention is a kind of method for producing mountain spring water with natural dense filtration process, and its feature is: its step comprises (a), adopts the stainless steel pipeline of fully enclosed smooth inner wall to be connected with container, and fully enclosed pipeline connection guarantees When the source water enters the production process, it will not be in contact with the outside world and will not be polluted by the outside world. (b), adopt manganese sand filter 1 to filter and remove the iron and manganese ions in the water, prevent the color-causing substance from flowing into the next process, meanwhile, an online detector of pH value is set up on the water inlet pipeline, and the pH value of the water inlet is checked Online detection, timely detection of changes in water quality. The manganese sand filter 1 of the present invention adopts a manganese sand filter with a specification of 2600mm×4000mm and 50T / h p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com