Control valve for a fuel injector that contains a pressure intensifier

A technology of fuel injectors and converters, which is applied in the direction of fuel injection pumps, fuel injection devices, charging systems, etc., which can solve the problem of precise and fast closing movement of valve pistons, which cannot achieve precise and fast closing movements. Large spring force , large structural space and other issues, to achieve the effect of small sealing diameter, simple manufacturing, and reduced leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

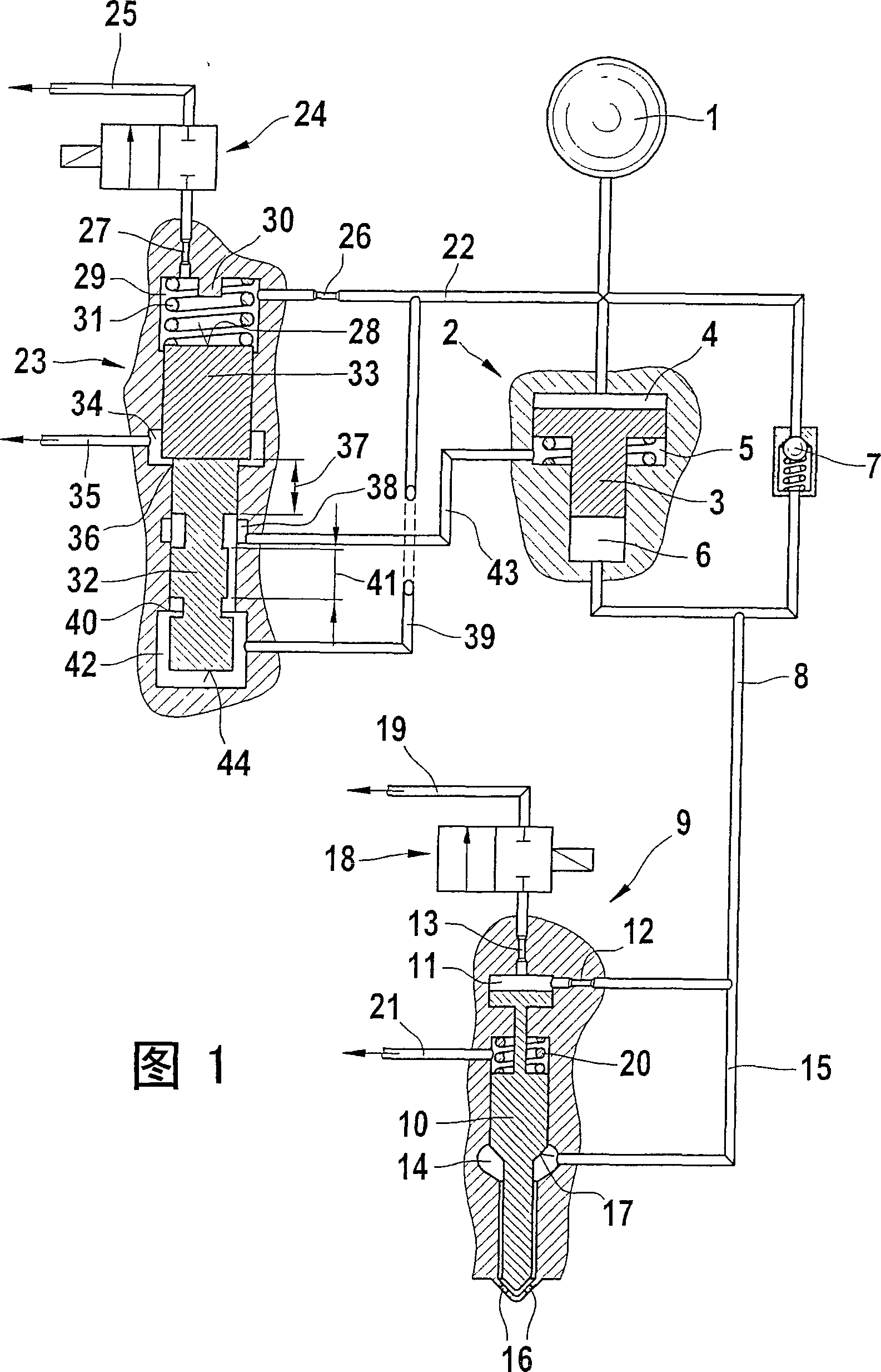

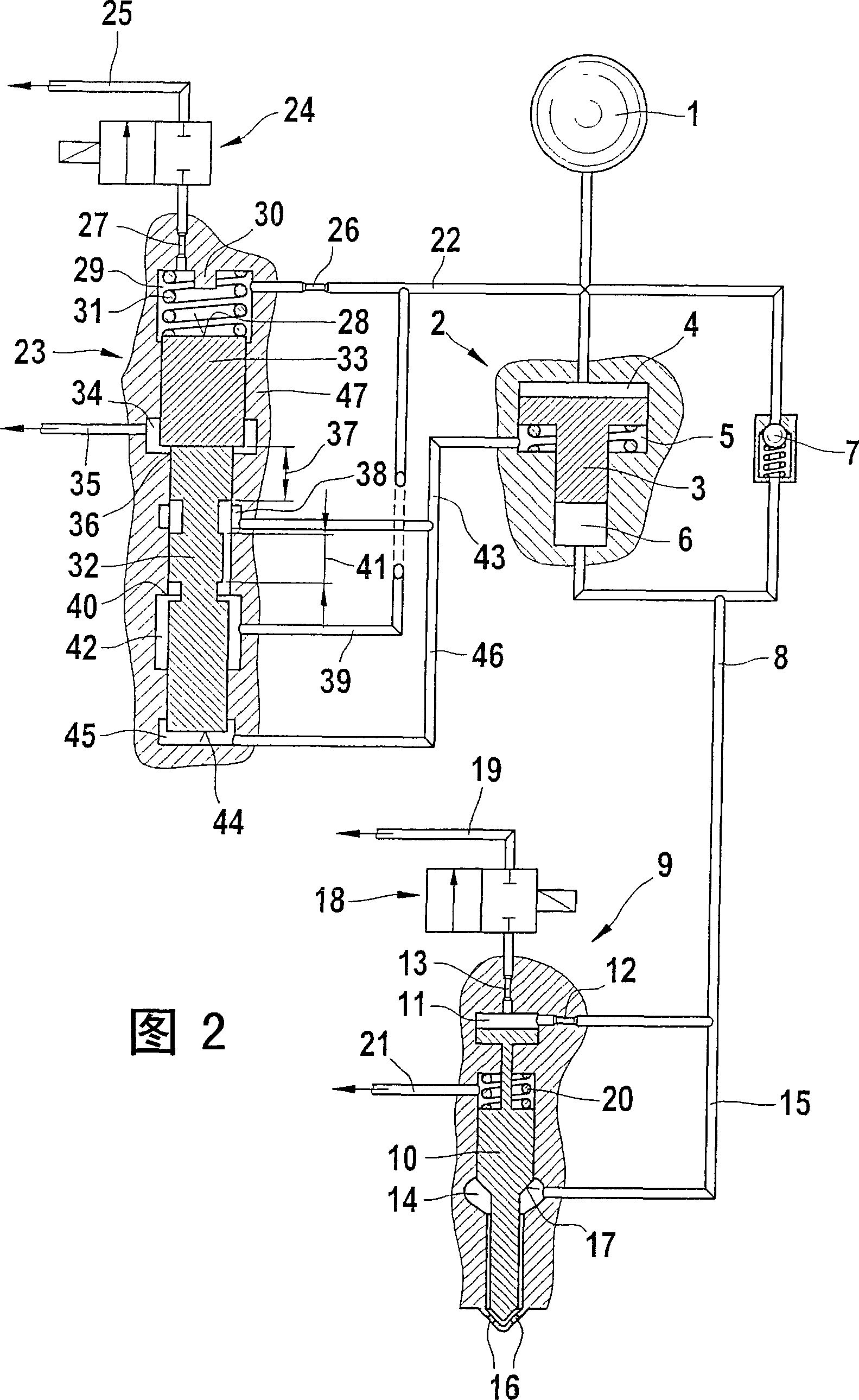

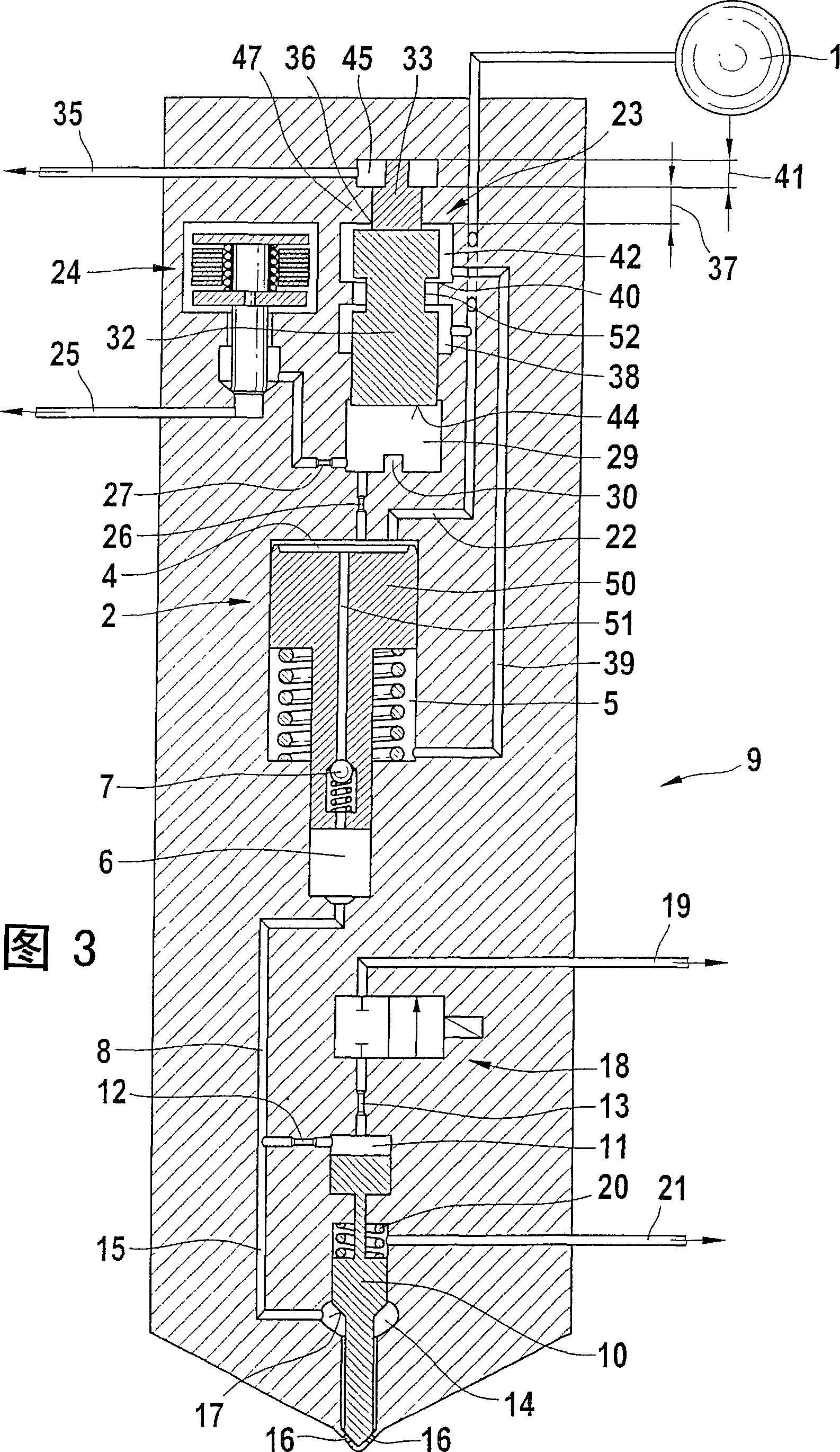

[0018] FIG. 1 shows a servo valve designed as a slide valve for controlling a pressure converter on a fuel injector.

[0019] Via a high-pressure source 1 , which can be a high-pressure accumulator (common rail) or a high-pressure fuel pump, a pressure converter 2 is charged with fuel under high pressure. The pressure transducer 2 comprises a working chamber 4 and a differential pressure chamber 5 (rear chamber), which are separated from one another by a transducer piston 3 . Furthermore, pressure transducer 2 includes a compression chamber 6 . A high-pressure line 8 branches off from this chamber, wherein a non-return valve 7 is accommodated in the refill branch of the pressure transducer 2 .

[0020] The fuel injector 9 is supplied with fuel at a shifted pressure—shifted according to the shift ratio of the pressure converter 2 —via the high-pressure line 8 . The high-pressure line 8 transitions into a nozzle chamber inlet 15 via which the nozzle chamber 14 is supplied with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com