Devices and methods for producing multiple x-ray beams from multiple locations

A technology for generating devices and x-rays, applied in the directions of X-ray tube parts, X-ray tubes, X-ray tube electrodes, etc., can solve the problems of limited observation angle, temperature sensitivity, limited resolution, etc., and achieve flexible controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

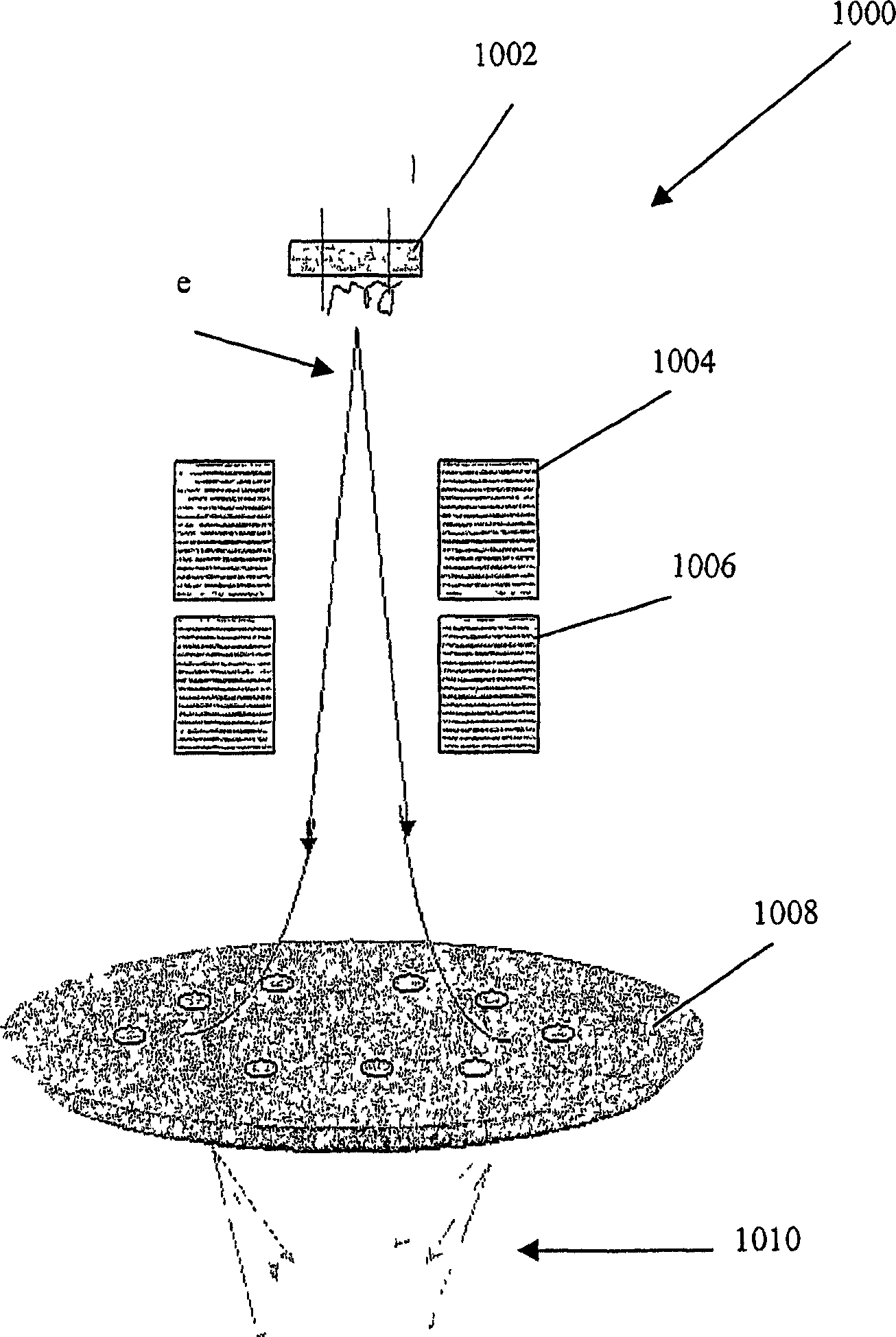

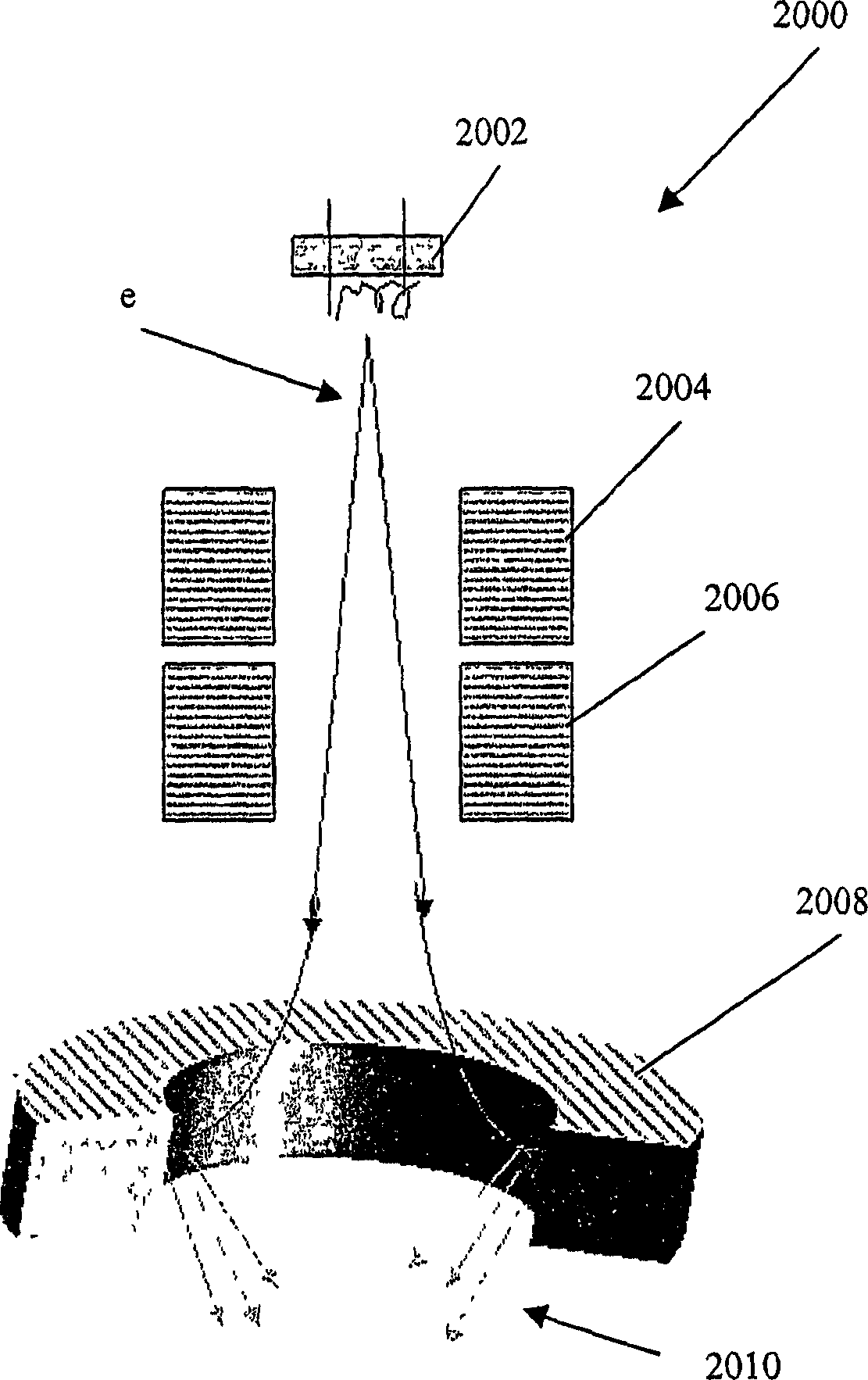

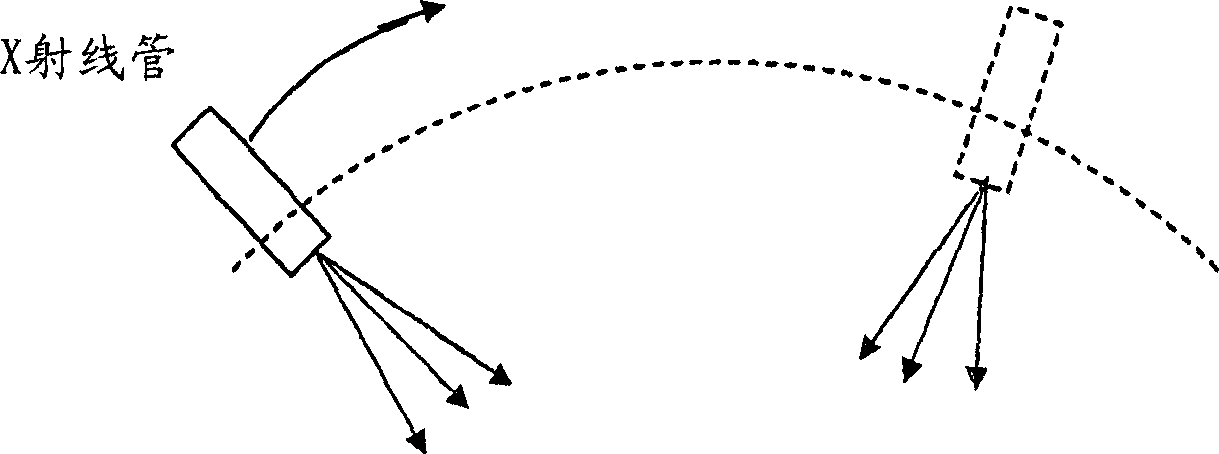

[0046] Exemplary devices and techniques of the present invention are described below with reference to the accompanying figures.

[0047] According to one embodiment of the present invention, such as Figure 5 As shown, the x-ray source comprises a field emission cathode 12 having a plurality of independently addressable electron emitting elements or "pixels" 11 . Cathode 12 has as Figure 6 The plane geometry shown. Anode 13 is opposed thereto and is separated from cathode 12 in vacuum chamber 14 by a finite gap distance. Electron emission from the pixel 11 on the cathode can be controlled by the gate electrode. Possible gate structures and arrangements used in this and other embodiments will be described in detail later. The X-ray source may comprise a single grid electrode, or more preferably comprises a grid electrode provided with a plurality of independently addressable cells, each cell controlling a respective pixel 11 on the cathode 12 . Electrons are extracted fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com