Gluing method of shoepad and appts thereof

A technology of insole and equipment, applied in the field of gluing method and equipment of insole, can solve problems such as damage to surface material, damage to human health, quality problems, etc., and achieve the effects of improving productivity, good air permeability, and simple structure of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

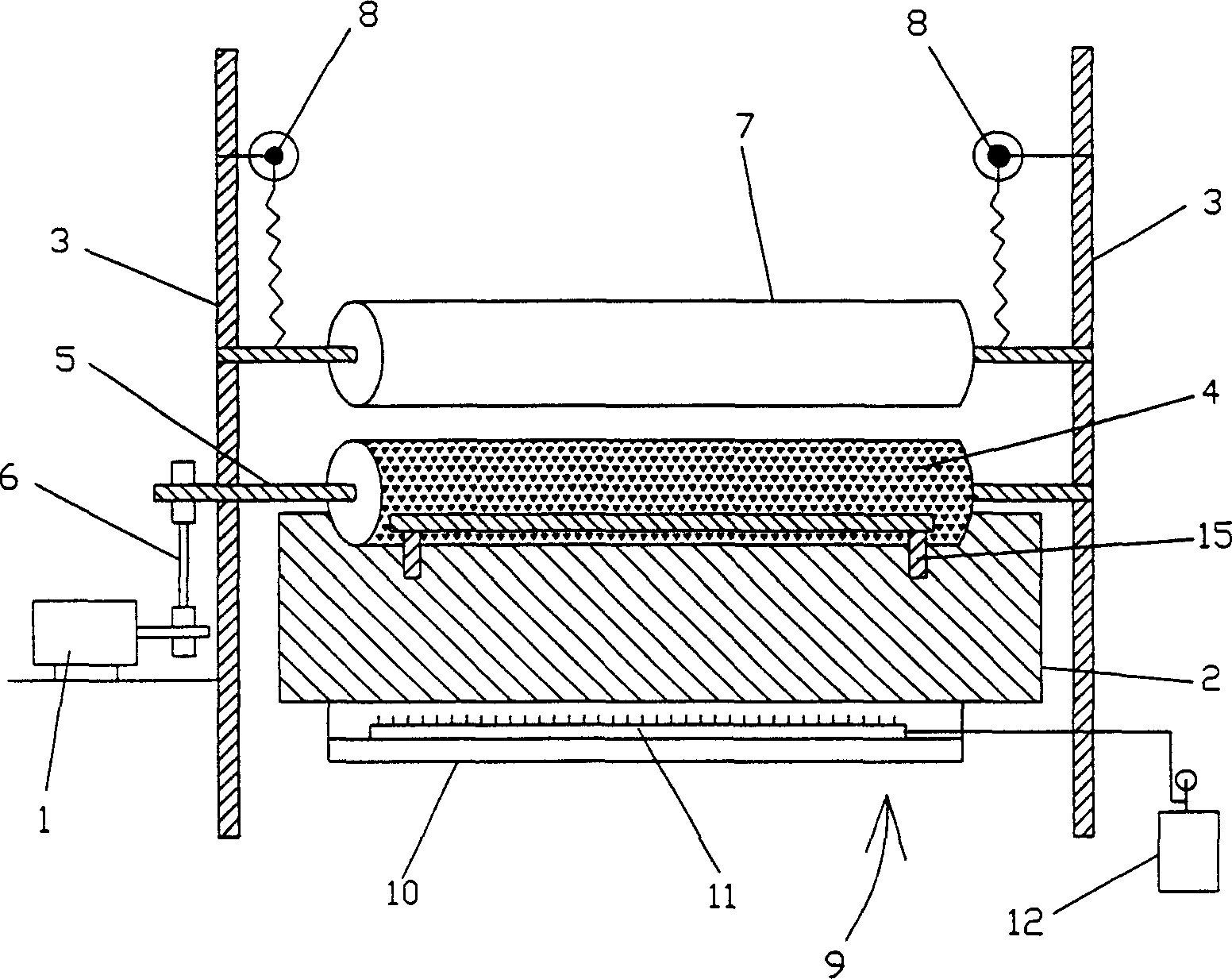

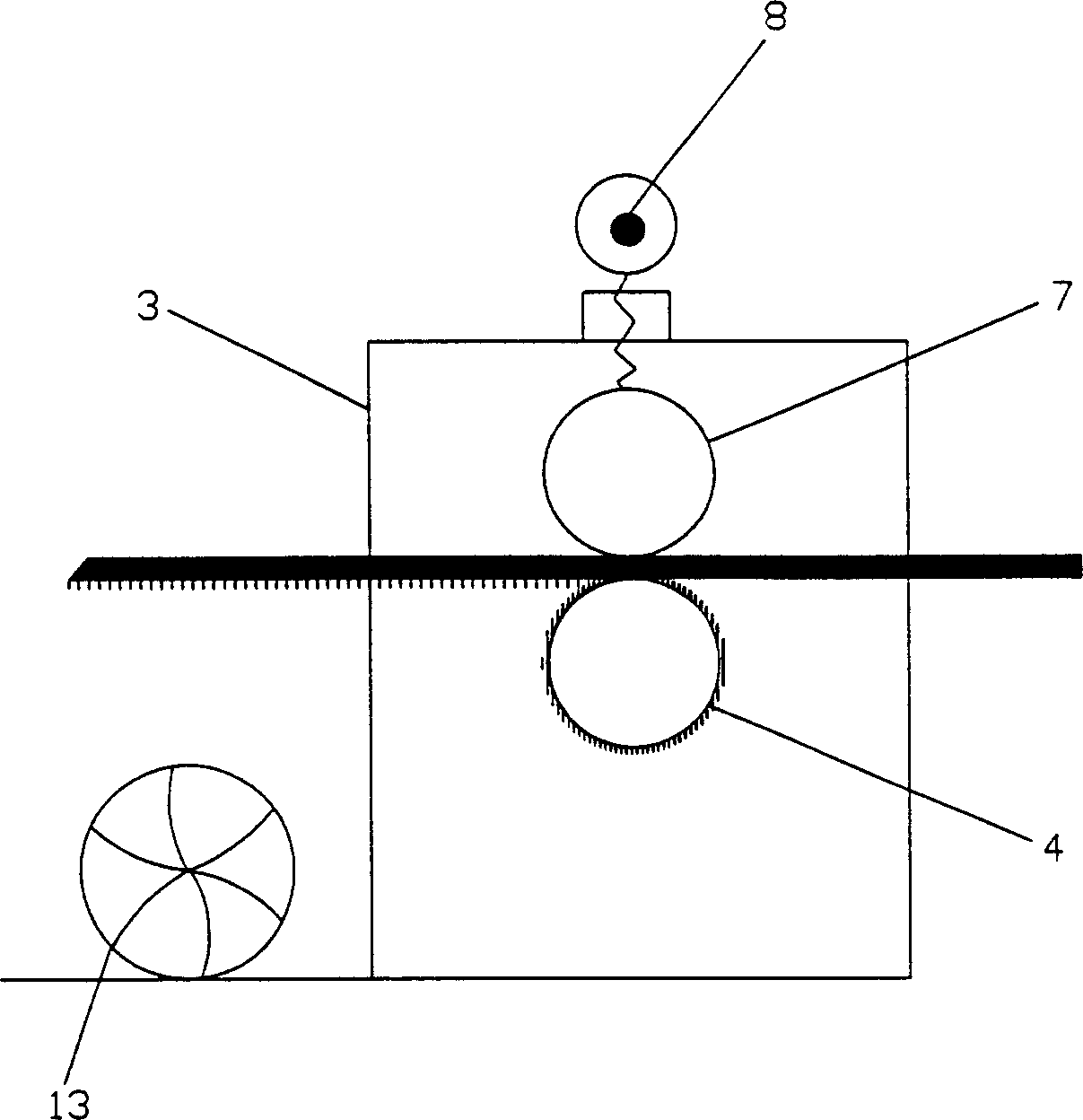

[0015] See figure 1 , 2 As shown, the technical solution adopted in the present invention is: its equipment includes motor 1, rubber groove 2, and glue groove 2 is fixed on the support 3, is provided with an upper rubber wheel 4 above the glue groove 2, and a part of the surface of the upper rubber wheel 4 is placed In the rubber tank 2, both ends of the upper rubber wheel 4 are hinged on the bracket 3 through a shaft 5, and one end of the upper rubber wheel 4 is connected to the output shaft of the motor 1 through a transmission device 6; a pressing wheel is also arranged directly above the upper rubber wheel 4 7. The pressing wheel 7 is fixed on the support 3, and the supporting wheel 3 is also provided with a pressing wheel adjustment device 8. In addition, a heating device 9 is also provided at the bottom of the glue tank 2. The heating device 9 includes a thermal insulation shell 10, a thermal insulation shell The combustion tube 11 in 10 and the gas bottle 12 that commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com