Hot air filling balance oil recovery technique 'zhanqian' mountain oil reservoir

A process technology and high-temperature air technology, which is applied in the technical field of high-temperature air-balanced oil recovery technology in ancient buried hill oil reservoirs, can solve problems such as mining, and achieve the effects of expanding oil layer volume, improving oil well productivity, and increasing production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

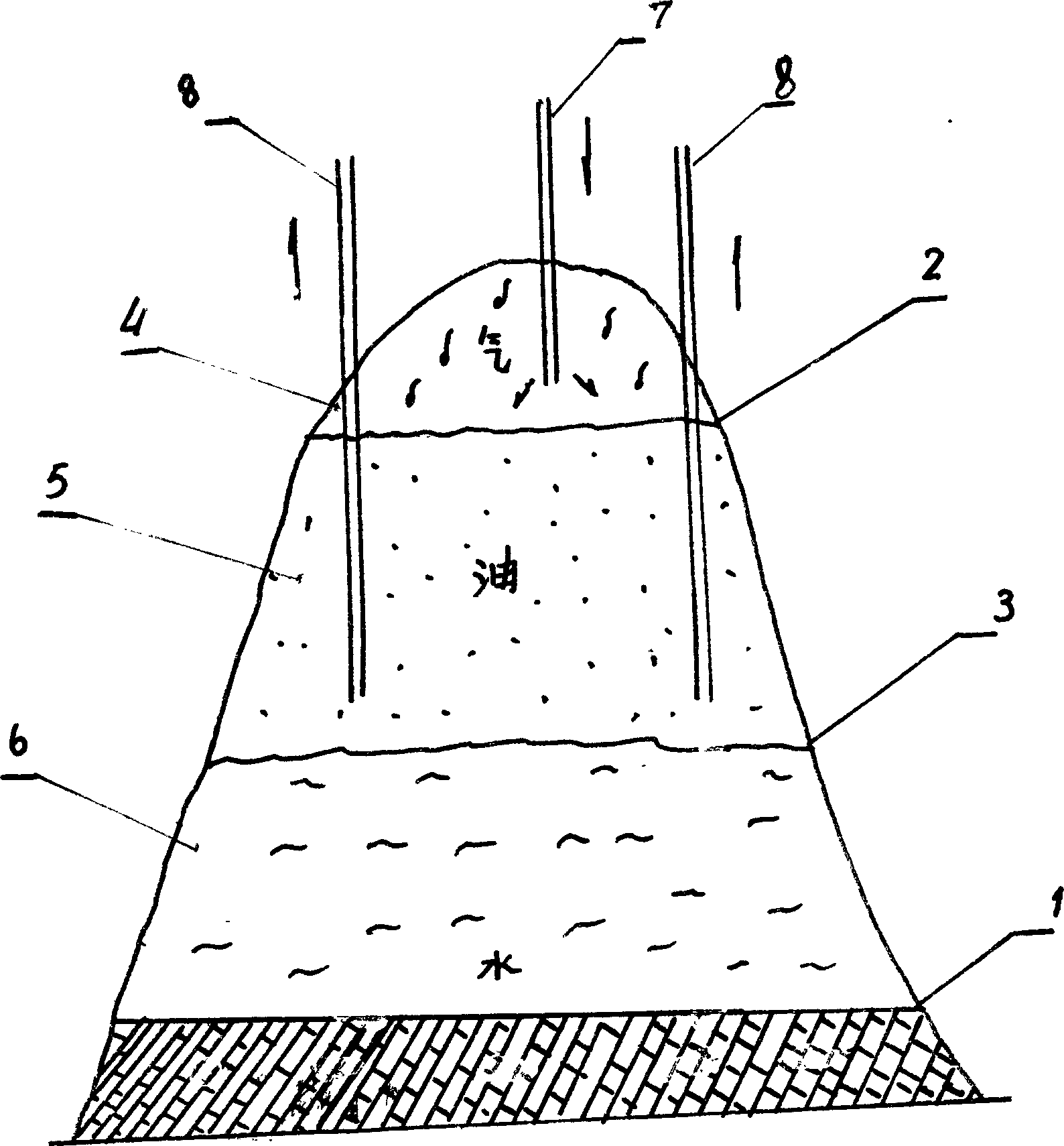

[0023] In Fig. 1, the physical parameters of the reservoir should be selected before the implementation of the present invention. This method is mainly used in carbonate buried hill, quartz buried hill structural reservoirs and thin oil reservoirs. The lithology should be carbonate and quartz buried hills and metamorphic rocks (hybrid migmatite, granulite, biotite lithic cataclysmic rock). There are structural fractures in the pores of the buried hill, and there are dual media of fractured pores and micropores in the fractures. The shape of the oil layer is a massive buried hill. For the old oil wells drilled in the rock mass with bottom water at the bottom of the buried hill, the old wells should be dealt with before construction. Plug the perforated well section and re-perforate according to the construction requirements. In addition, the old oil well that has been exploited has a water content above 95%, that is, it can be used when there is no oil production value at presen...

Embodiment 2

[0025] When the buried hill oil reservoir is exploited, after the first step of the embodiment is completed, the oil is extracted from the reservoir above the new oil-water interface 3 after the gas injection in the old oil well, and when the recovery process occurs such as the gas injection When the newly-produced oil-water interface 3 moves down, that is, when the production well 8 sees the gas display, the method of injecting water to the bottom of the buried hill through the water injection well can be adopted to adjust the oil-water interface to maintain the original formation pressure in the well with sufficient energy.

Embodiment 3

[0027] The position of the newly produced oil-water interface 3 after gas injection in the present invention determines the amount of oil produced by the oil well, so it is very important to control the position of this interface. Determined by hot air at 350°C, the optimum position of the newly produced oil-water interface 3 after gas injection should be controlled at 2 / 3 of the oil-water interface 2 below the oil-water interface 2 after the bottom water rises before gas injection in the original old well after production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com