Method of using linear dynamo oil recovery and linear dynamo oil pump

A technology of linear motor and oil pump, which is applied to machines/engines, pumps with flexible working elements, pumps, etc., to reduce the power consumption of a single well, solve the problem of eccentric wear of rods and pipes, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

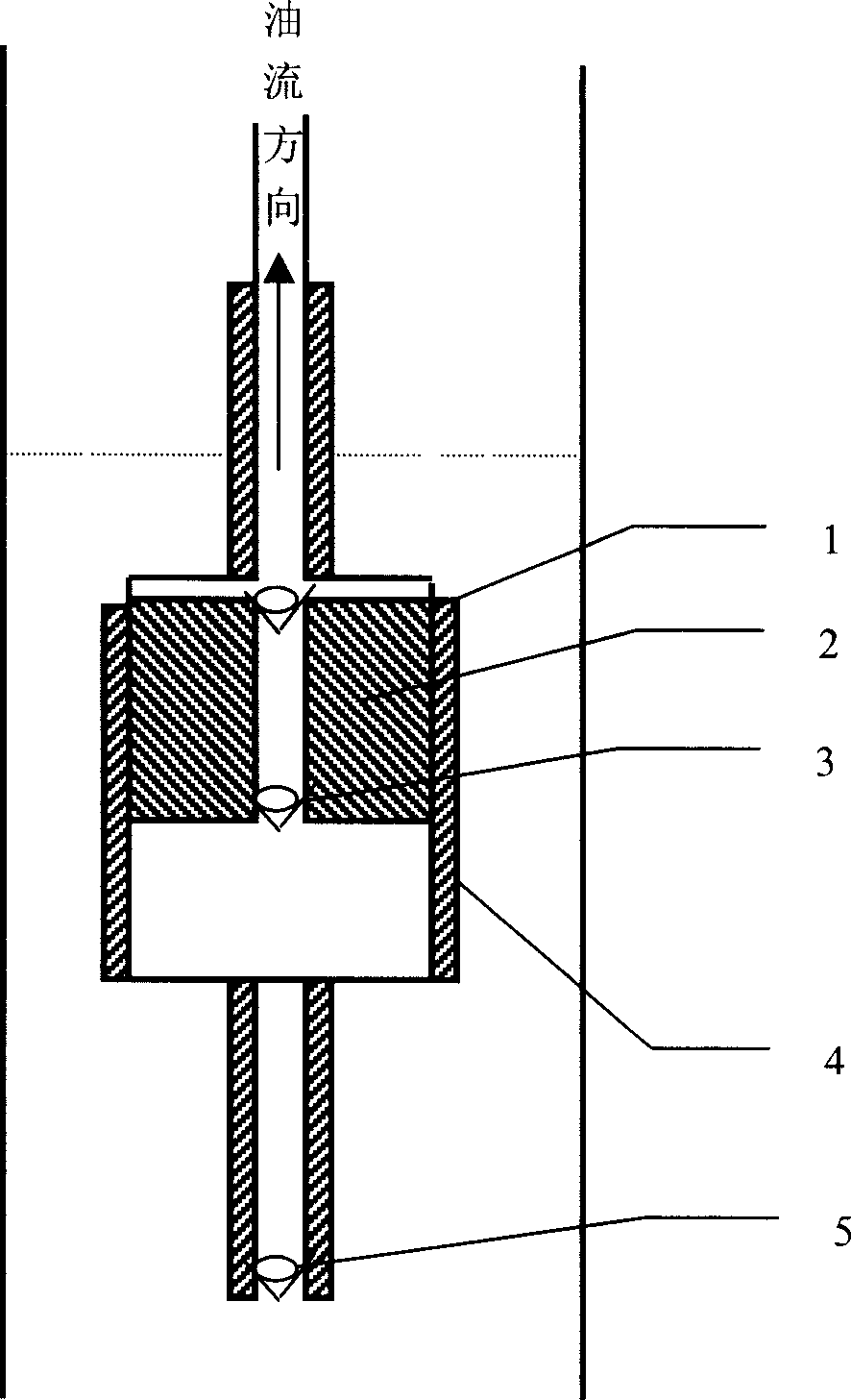

[0014] Below in conjunction with embodiment the present invention is described in further detail: referring to accompanying drawing, the method for extracting oil with linear motor is to use linear motor as the power drive equipment of oil well pump or double as oil well pump with linear motor to extract crude oil, that is to say, use linear motor That is, it is used as power-driven equipment and as an oil well pump. When the linear motor is used as the power drive equipment of the oil well pump, the linear motor is lowered into the well through the oil pipe and connected with the rod oil well pump. The connection method between the linear motor and the rod oil pump is to connect the motor mover 2 of the linear motor with the plunger of the rod oil pump through the connecting piece. The linear motor can be installed above the rod oil pump or installed on the rod pump. Below the oil pump. The linear motor oil well pump used in the above method includes the floating valve 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com