Concrete material content on-line detection system based on pulse fast heating neutron instantaneous Gamna radiation malysis tech

A technology of prompt gamma and analysis technology, which is applied in the field of online detection system of cement material composition, to achieve the effect of improving cement quality, increasing service life and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and implementation the utility model is described further.

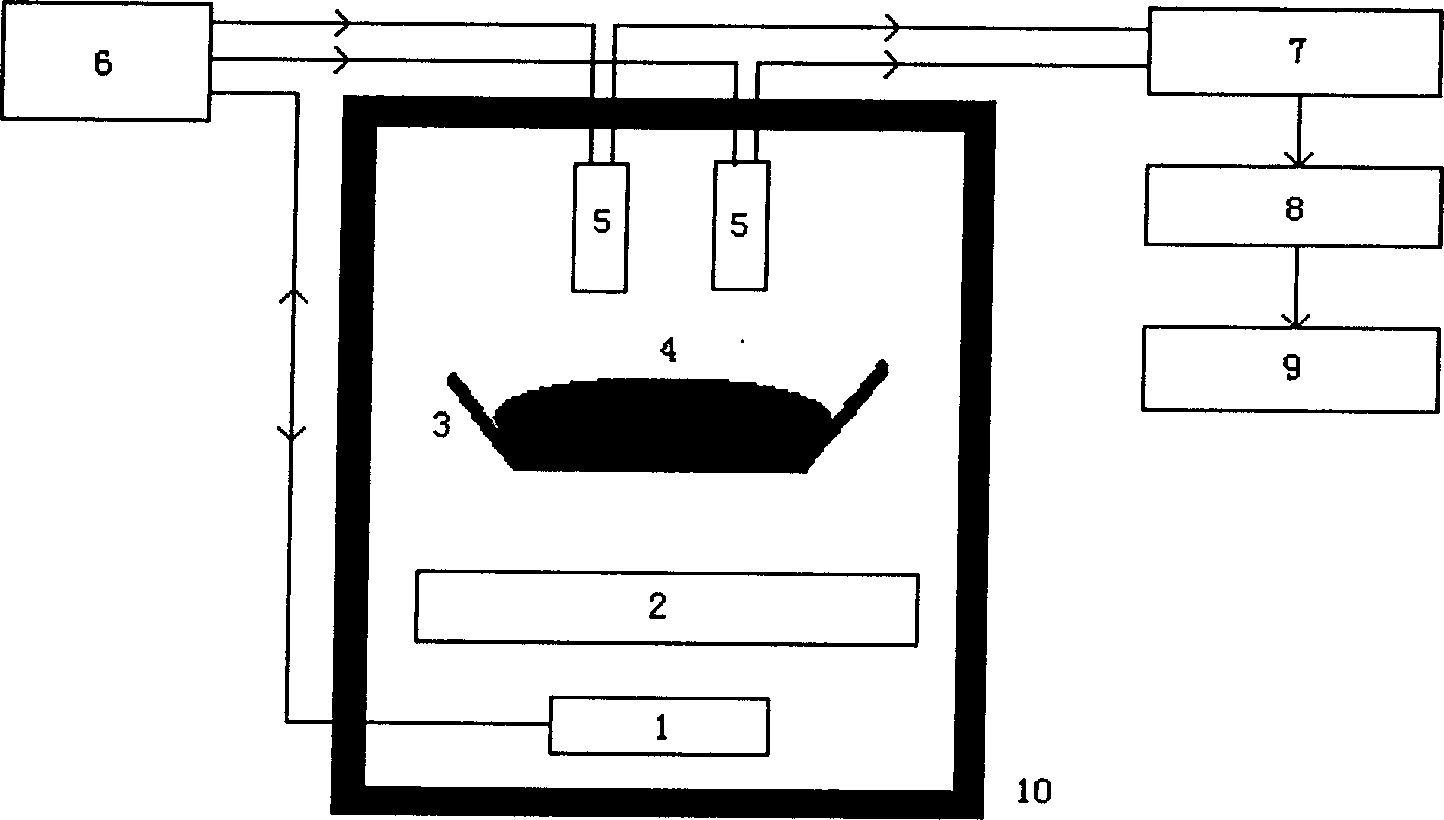

[0017] Such as figure 1 shown.

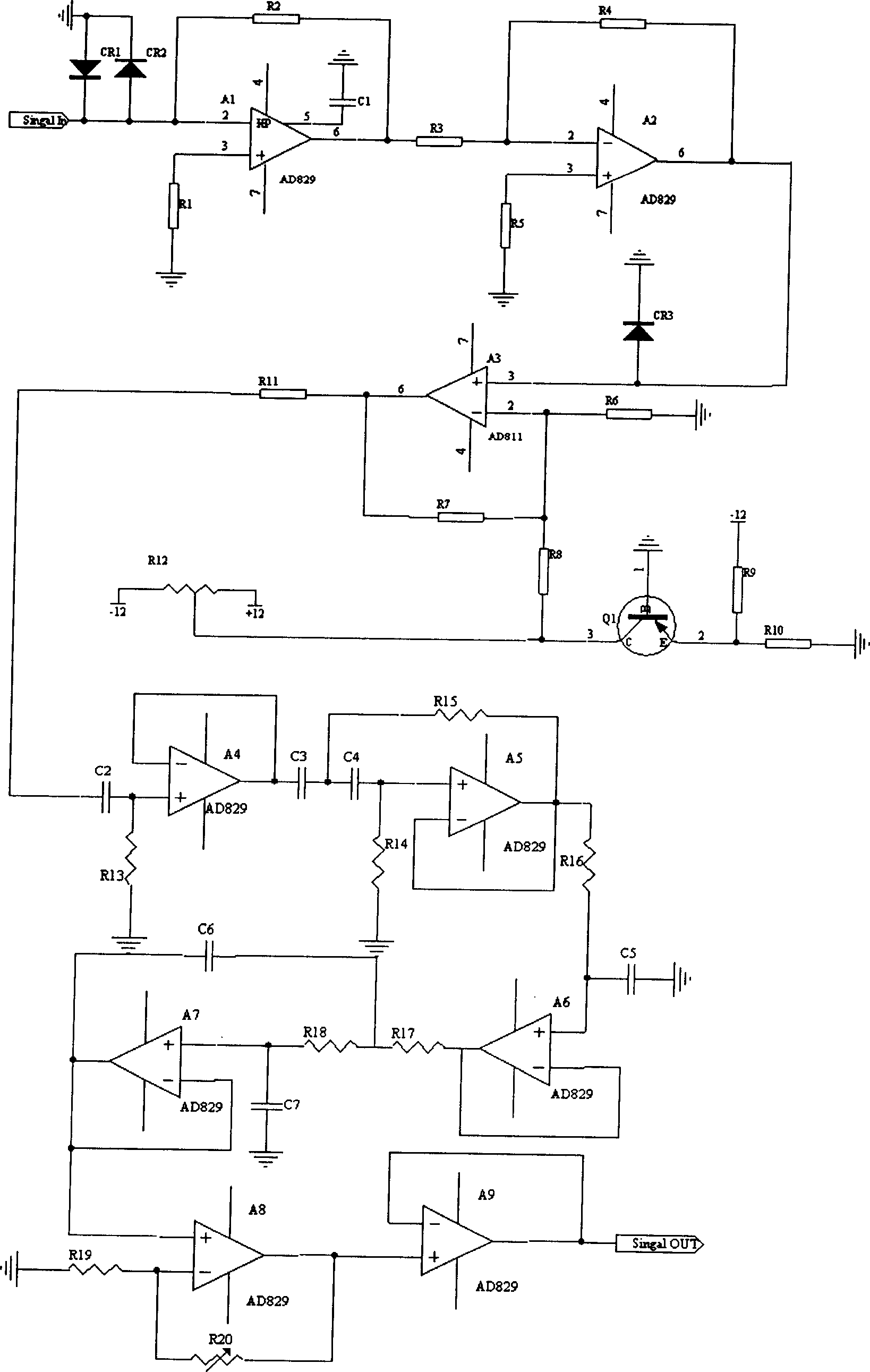

[0018] An online detection system for cement material components based on pulsed fast thermal neutron prompt gamma ray analysis technology, including a neutron generator 1, a moderator 2, two (or more than two) gamma ray detectors 5, Electric control cabinet 6, electronic amplification system 7, data acquisition system 8, computer data processing and display system 9, composite shielding protection system 10, wherein electric control cabinet 6, electronic amplification system 7, data acquisition system 8, computer data processing and display System 9 is installed in a control room, neutron generator 1, moderator 2, gamma ray detector 5, conveyor belt 3 are installed in composite shielding protection system 10, conveyor belt 3 passes through composite shielding protection system 10, waits The detection cement raw material 4 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com