Microlens array sheet using mems and manufacturing method thereof

A microlens array and microlens technology, applied in the direction of lenses, separation methods, chemical instruments and methods, etc., can solve the problem that the boundary area cannot have a vertical cross section, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now, preferred embodiments of the present invention will be described with reference to the accompanying drawings. In the following description, known functions and constructions incorporated herein may obscure the subject matter of the present invention, and therefore, a detailed description thereof will be omitted.

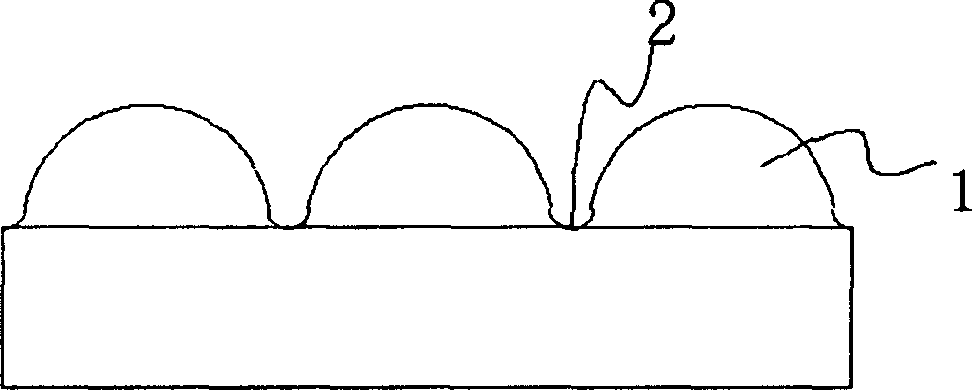

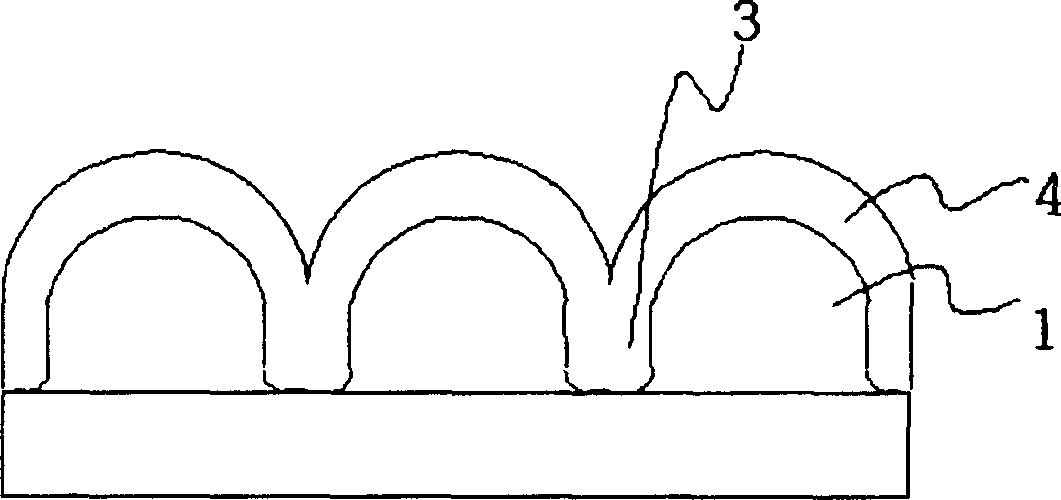

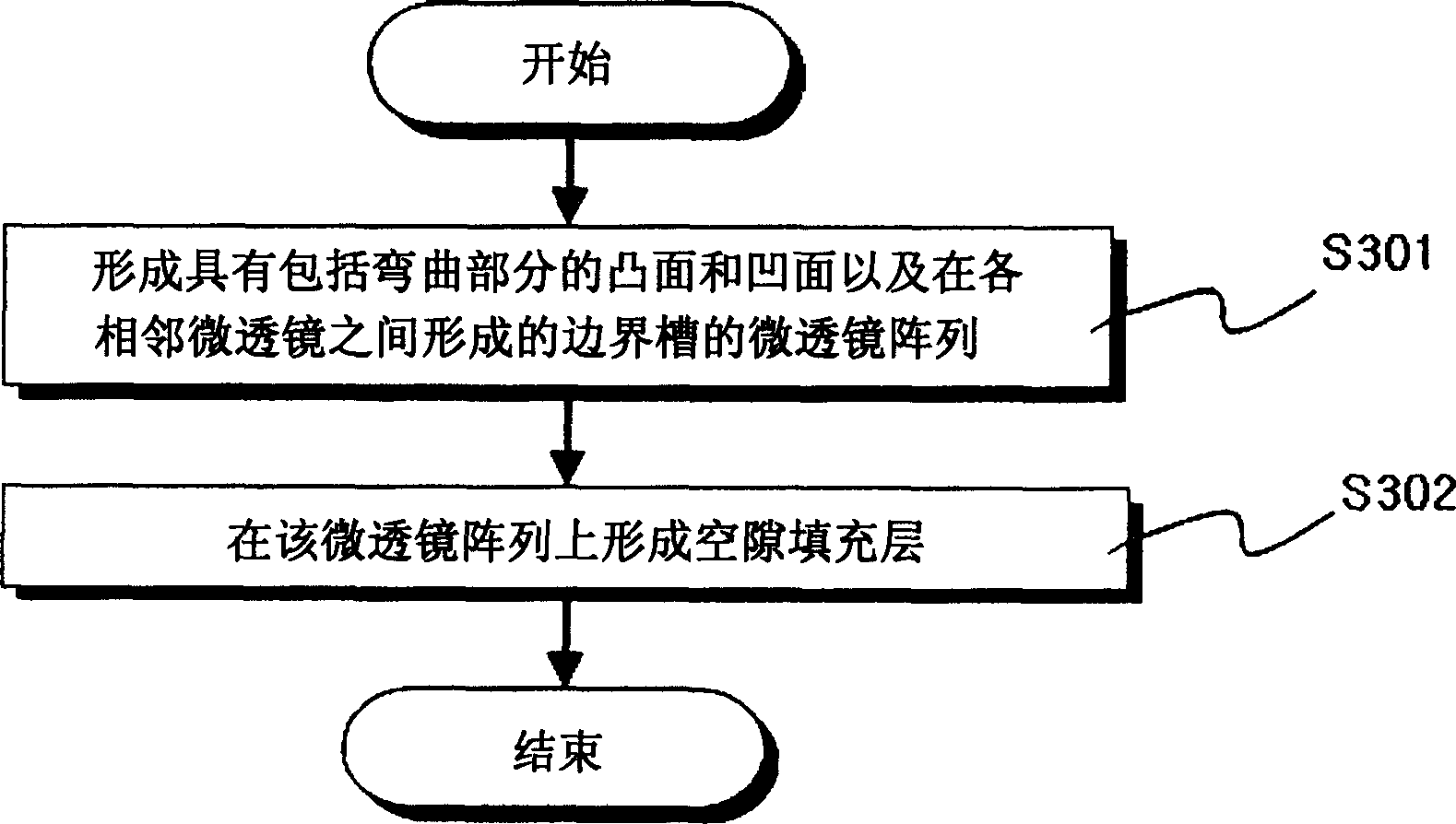

[0019] figure 2 is a cross-sectional view of a microlens array sheet using microfabrication according to an embodiment of the present invention.

[0020] In an embodiment of the present invention, the microlens array sheet includes a microlens array 1 and a gap-filling layer 4 .

[0021] The embodiment of the present invention schematically illustrates a method for forming one or more boundary grooves 3 in the microlens array 1 .

[0022] refer to figure 2 , in the laser micromachining step of the microlens array 1, the boundary groove 3 is formed in the microlens array 1, so that the light loss in the boundary area between each adjacent microlens is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com