Self-walking column type overhead operation platform

An aerial work platform and self-propelled technology, which is applied in the direction of lifting devices, can solve the problems of long preparation time and auxiliary work time, difficult operation of the work platform against the wall, and low work efficiency, so as to reduce the preparation time and auxiliary work Time, easy to change the working position, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

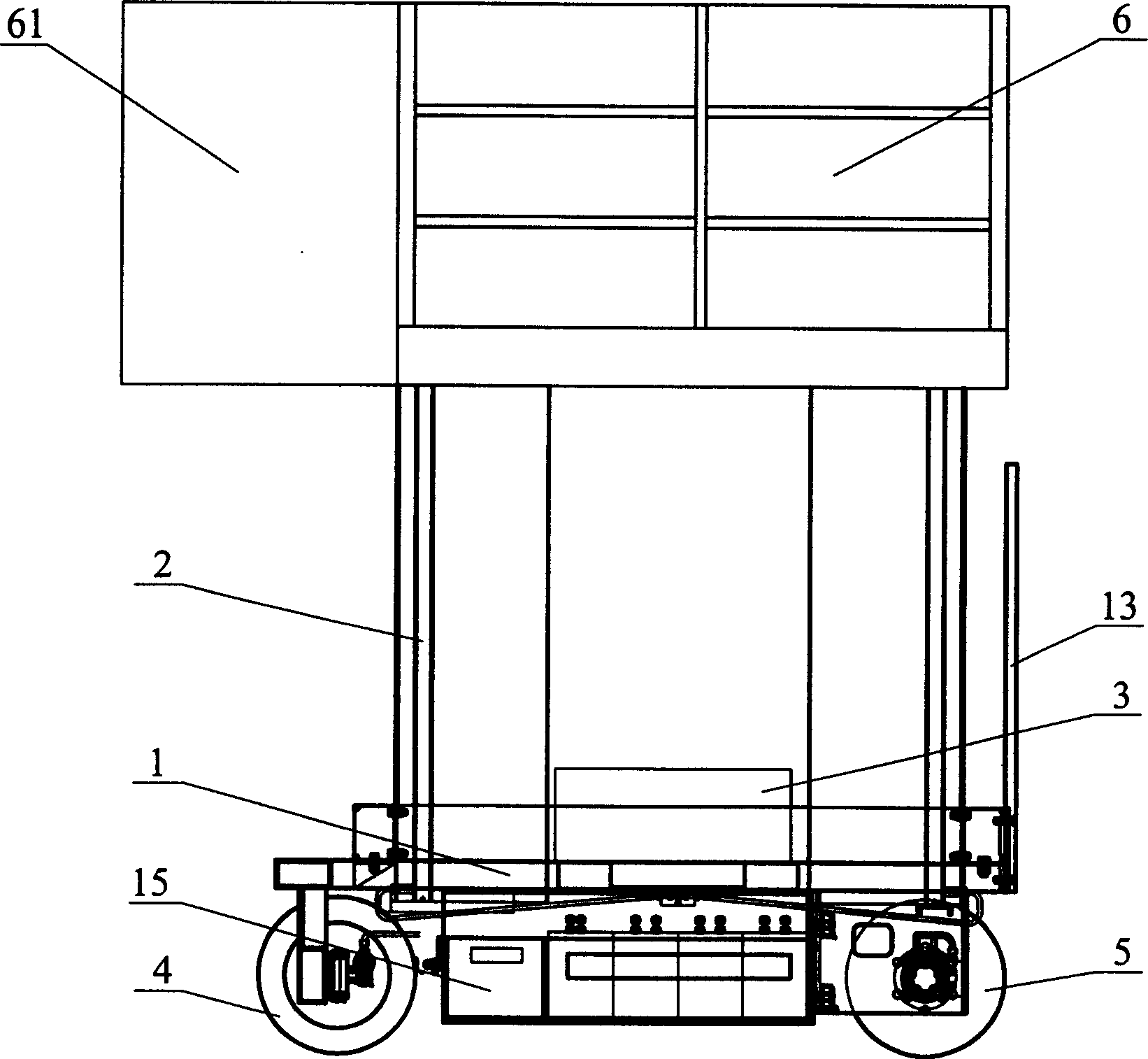

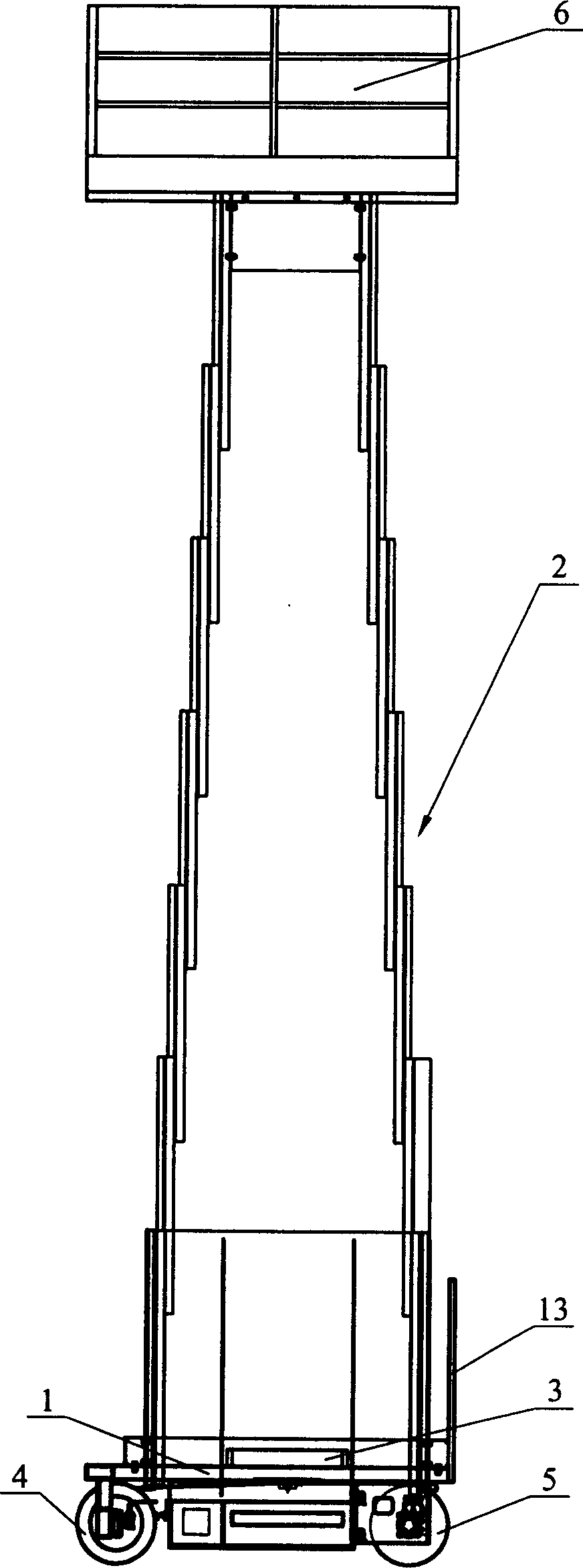

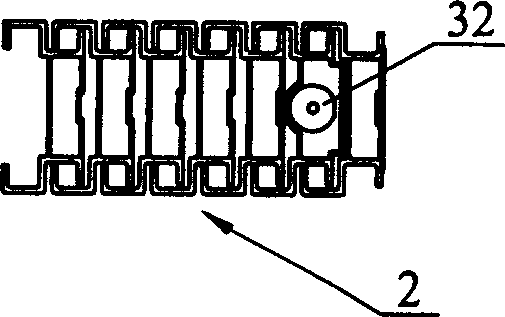

[0023] Such as Figure 1~4 As shown, the self-propelled mast-type aerial work platform includes a chassis 1, a mast 2, a hydraulic system, a traveling device and a workbench 6, wherein the chassis 1 is a box structure, and a control device, a charger 15, The hydraulic station 3 and the working ladder 13, the control device includes various opening and closing devices and buttons that control the movements of each part of the whole machine, and four sets of masts 2 are evenly distributed on the chassis 1, so that the working center of the whole machine is located in the four sets of masts. Between the columns 2, the stability of the whole machine is ensured. Each group of masts is provided with a lifting hydraulic cylinder 32 connected to the hydraulic station 3 through an oil pipe 31. There is a telescopic sub-table 61 on the side; at the same time, two traveling driving wheels 5 and two steering wheels 4 are arranged separately under the chassis 1, so that the center of gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com