Method of production of fatty acid alkyl esters and/or glycerine and fatty acid alkyl ester-containing composition

A technology of fatty acid alkyl esters and glycerin, which is applied in fatty acid esterification, chemical instruments and methods, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

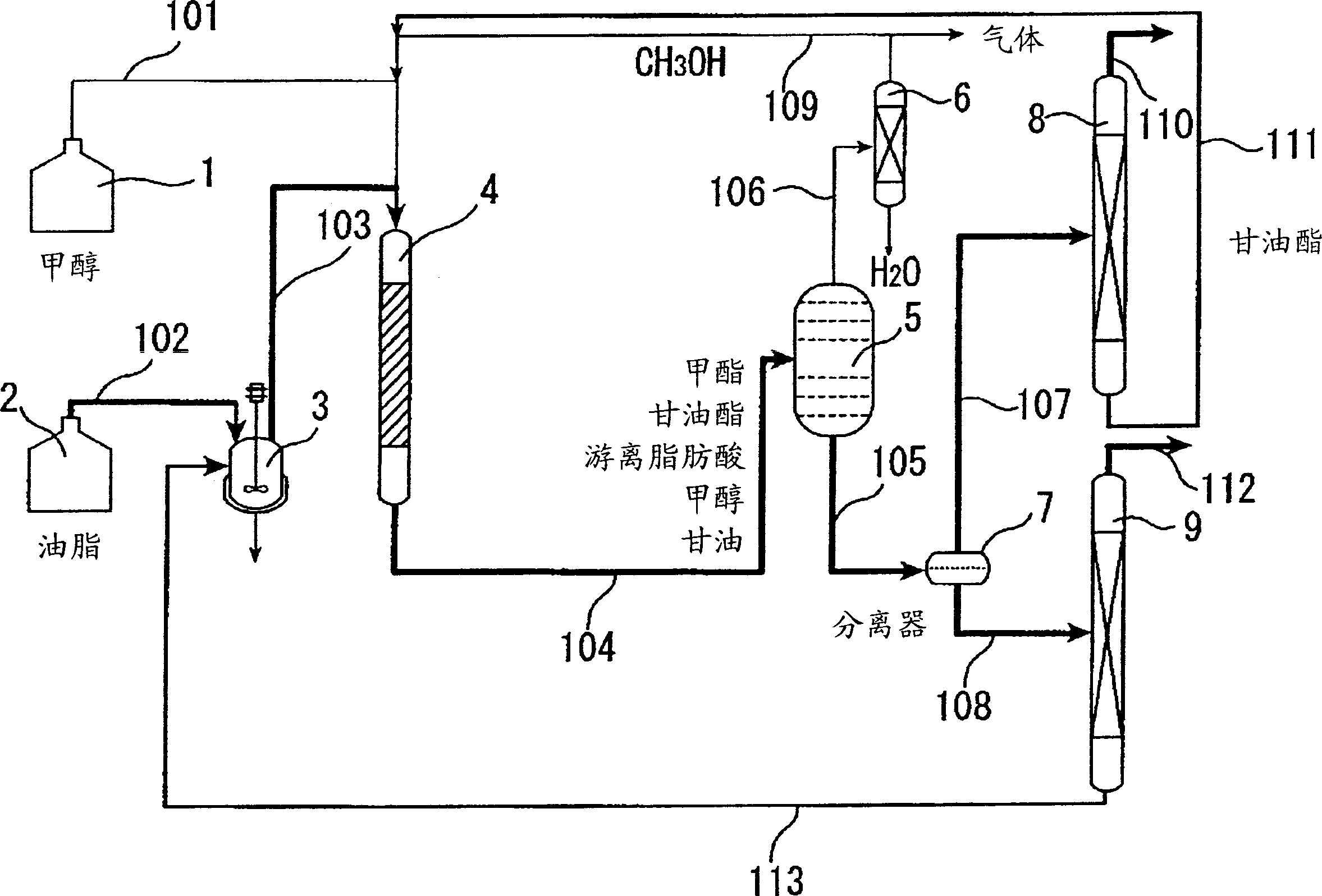

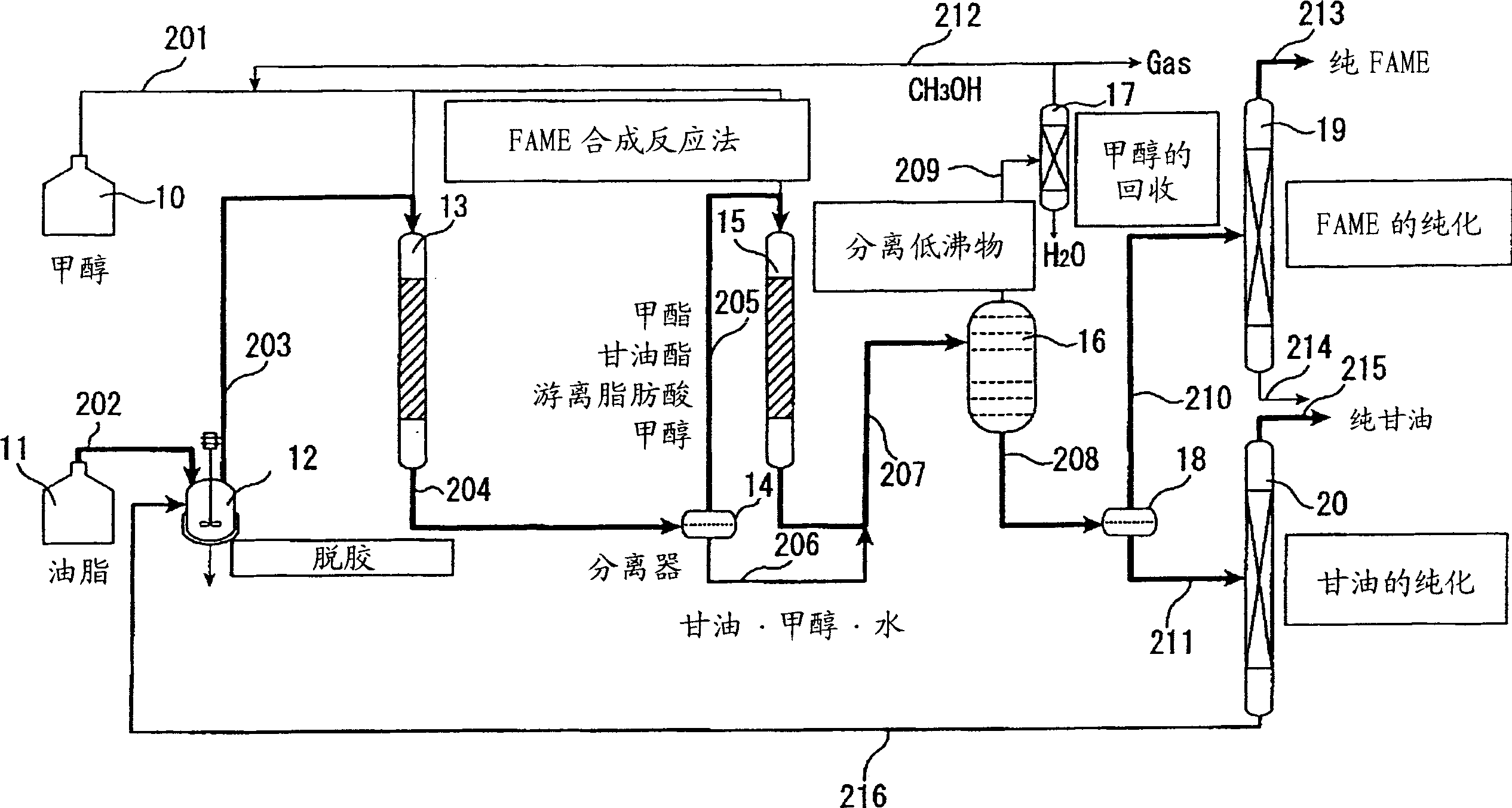

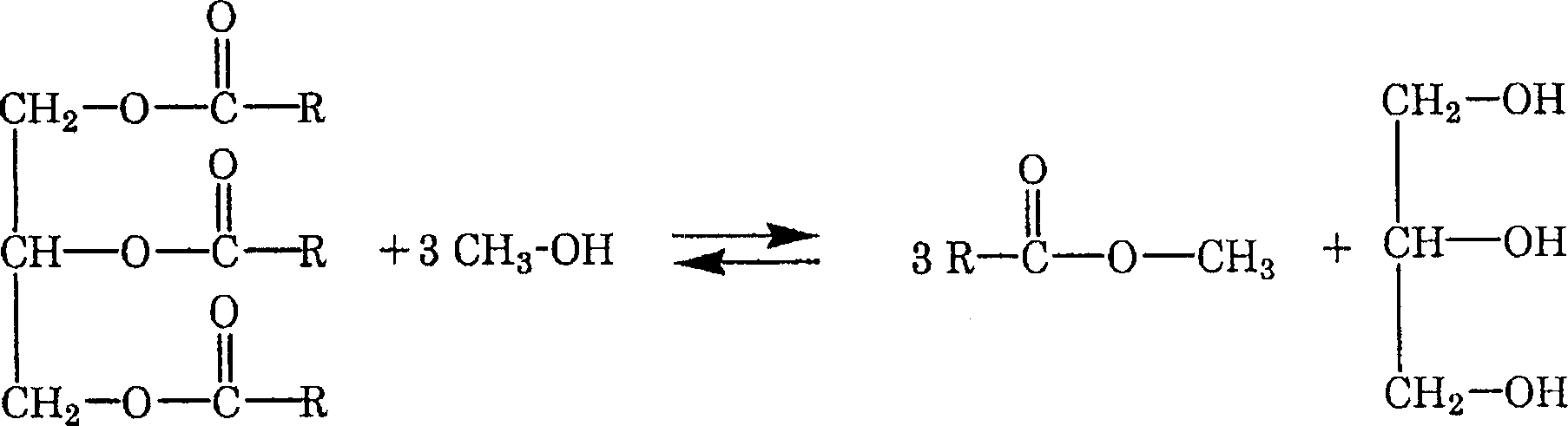

[0016] Next, the present invention will be described in detail.

[0017] According to the invention, a fat or oil is reacted with an alcohol using an insoluble solid catalyst. In the case of the manufacture of fatty acid alkyl esters, in addition to the above mentioned effects, the content of fatty acid alkyl esters in the ester phase is improved due to improved conversion and improved recovery of fatty acid alkyl esters from the glycerin phase , so that the purification cost can be reduced. Furthermore, unlike the conventional production method using a homogeneous catalyst, the step of removing the catalyst by washing with water is unnecessary; in this regard, the method of the present invention is an advantageous method. Also in the case of glycerol production, recovery of glycerin from the ester phase is improved and since dilution with water is unnecessary, glycerin of high concentration and high purity can be obtained in the glycerin phase, thereby reducing purification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com