Nonaqueous electrolyte battery

A non-aqueous electrolyte and battery technology, applied in the direction of secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of low metal foil adhesion, battery voltage drop, peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0084] (Example)

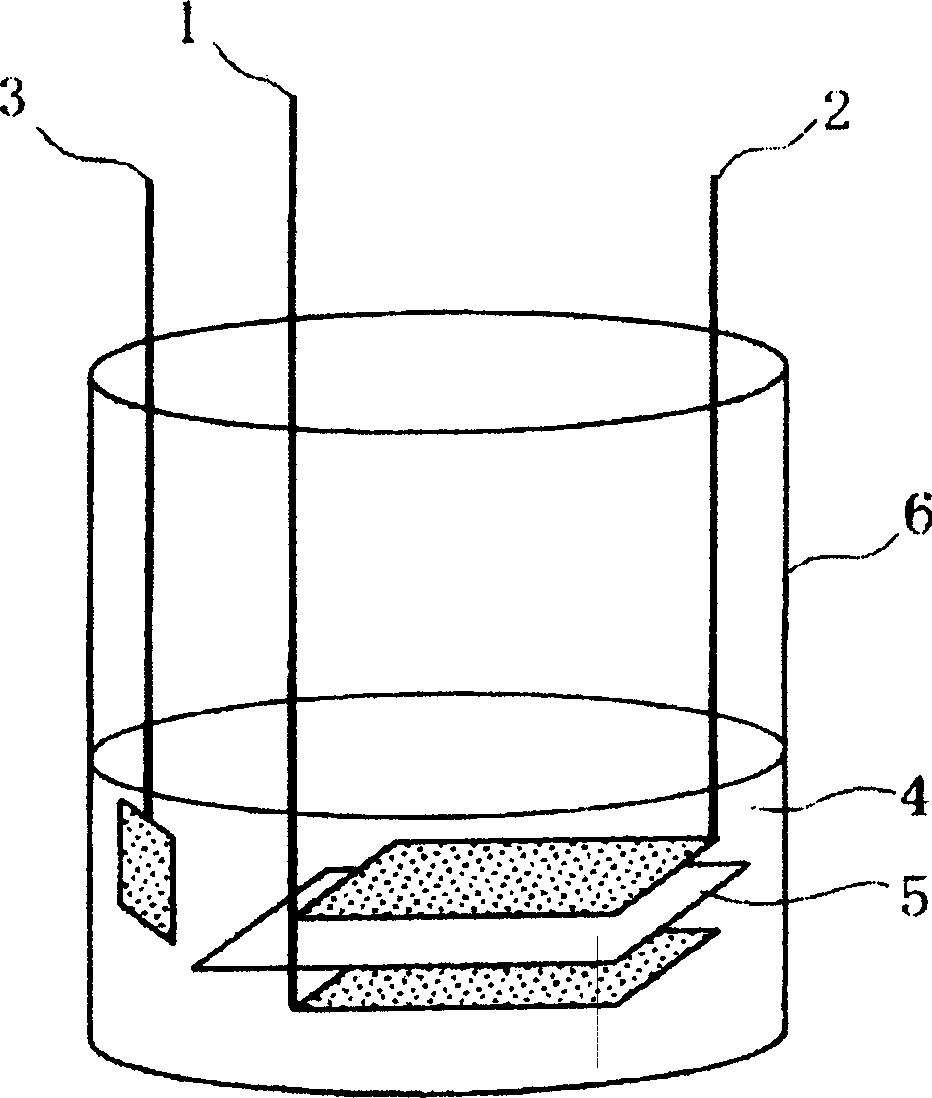

[0085] As an example, a positive electrode and a test battery were fabricated in the same manner as in the best mode for carrying out the invention.

[0086] Hereinafter, the positive electrode and the experimental battery thus fabricated are referred to as the positive electrode a of the present invention and the positive electrode of the present invention, respectively.

[0087] Battery A.

Embodiment 1

[0144] A battery was produced in the same manner as in Example 1 of the first example, except that a positive electrode was produced as follows.

[0145] Hereinafter, the battery produced in this way is referred to as the battery B1 of the present invention.

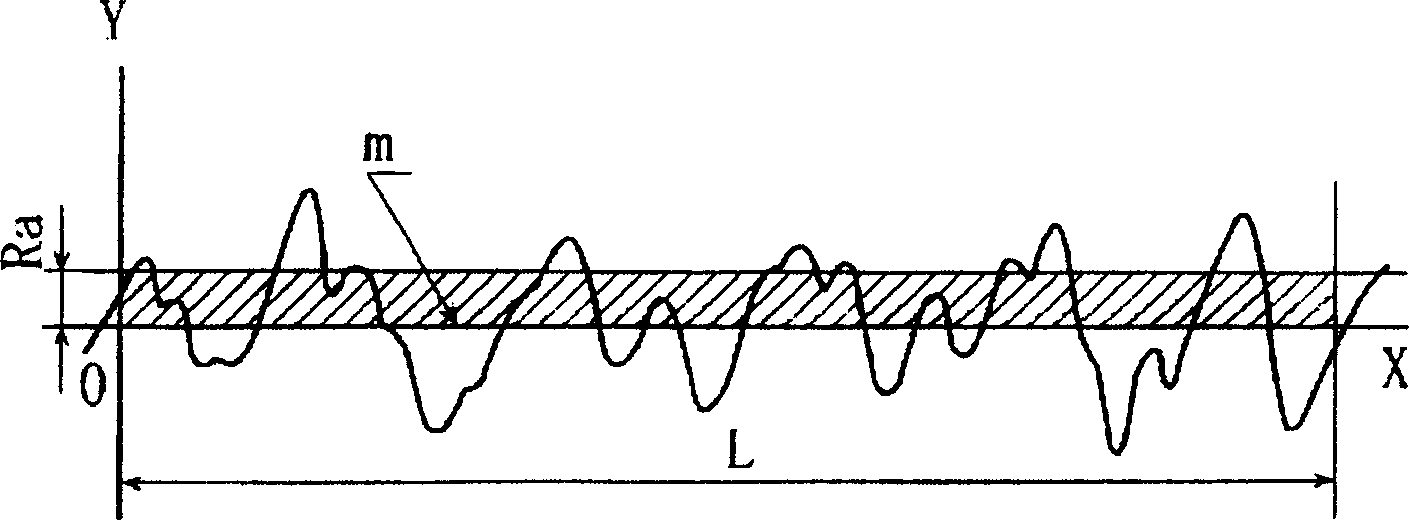

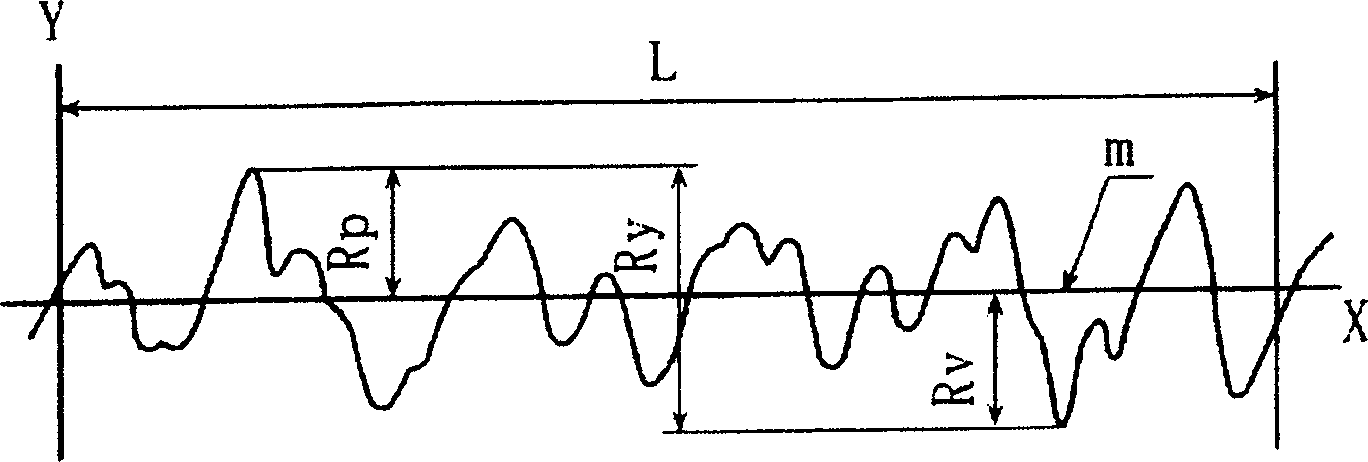

[0146] First, according to the lithium iron phosphate (LiFePO 4 ) reaches 85% by mass of the positive electrode active material containing layer as a whole, and carbon black (BET specific surface area: 70m 2 / g) was measured so that it might become 10 mass % of the whole positive electrode active material containing layer, and both were mixed. Then, to the mixture, polyacrylonitrile (PAN) was added as a binder to make it 5% by mass of the entire positive electrode active material-containing layer, and an appropriate amount of N-methylpyrrolidone (NMP) solution was added as a solvent. , made a slurry by mixing. Then, the slurry was applied to a surface with a surface roughness Ra of 0.14 μm (Ra=0.14 μm) and a maximum he...

Embodiment 2

[0163] Except for carbon black as a conductive agent, using a BET specific surface area of 39m 2 A test battery was produced in the same manner as in Example 1, except for the material used in the test example 1.

[0164] The battery produced in this way is hereinafter referred to as battery B2 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com