Waste gas treatment device capable of simultaneously recovering waste heat and removing contaminant

A waste gas treatment device and waste gas treatment technology, which are applied in waste heat treatment, energy industry, climate sustainability, etc., can solve the problems of large investment and floor space, increase heat loss, and large exhaust gas flow resistance, and achieve investment savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

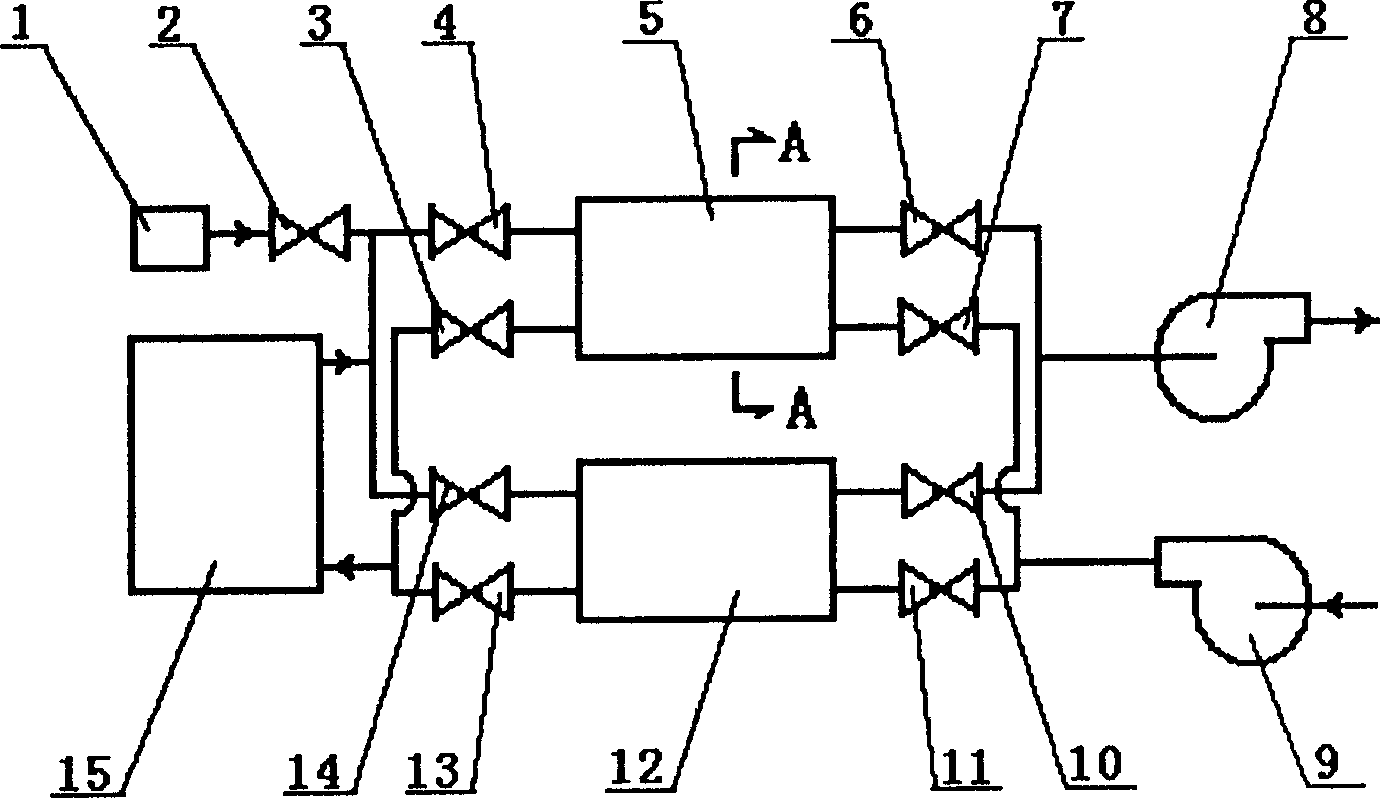

[0021] Depend on figure 1 , figure 2 and image 3 As shown, the present invention may include exhaust gas treatment unit, reducing agent NH 3 Storage tank 1, valve 2, industrial furnace 15, induced draft fan 8 and blower 9.

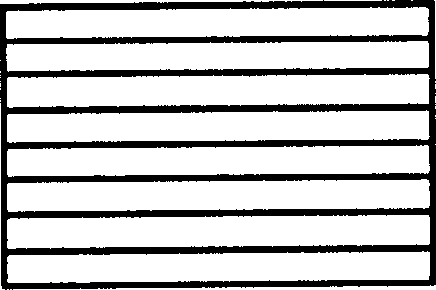

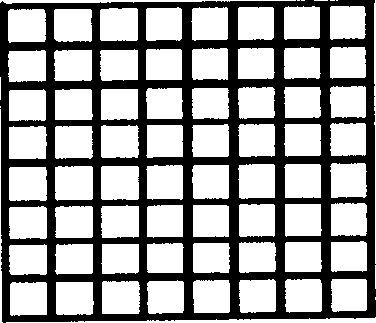

[0022] The structure of the waste gas treatment unit is that one end of the first porous ceramic regenerator 5 is connected to the inlet end of the first valve 3 and the outlet end of the second valve 4, and the other end of the first porous ceramic regenerator 5 is connected to the second valve 4. The inlet end of the third valve 6 is connected with the outlet end of the fourth valve 7, one end of the second porous ceramic regenerator 12 is connected with the inlet end of the fifth valve 13 and the outlet end of the sixth valve 14, and the second porous ceramic The other end of the heat storage chamber 12 is connected with the inlet end of the seventh valve 10 and the outlet end of the eighth valve 11; Covered with a redox catalyst. The redox catal...

Embodiment 2

[0028] Depend on Figure 4 shown, with figure 1 The difference is that: figure 1 The first valve 3 , the second valve 4 , the fifth valve 13 and the sixth valve 14 in the shown exhaust gas treatment unit are replaced by a first two-position four-way rotary valve 16 .

Embodiment 3

[0030] Depend on Figure 5 shown, with figure 1 The difference is that: figure 1 The four valves of the third valve 6 , the fourth valve 7 , the seventh valve 10 and the eighth valve 11 in the shown exhaust gas treatment unit are replaced by a second two-position four-way rotary valve 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com