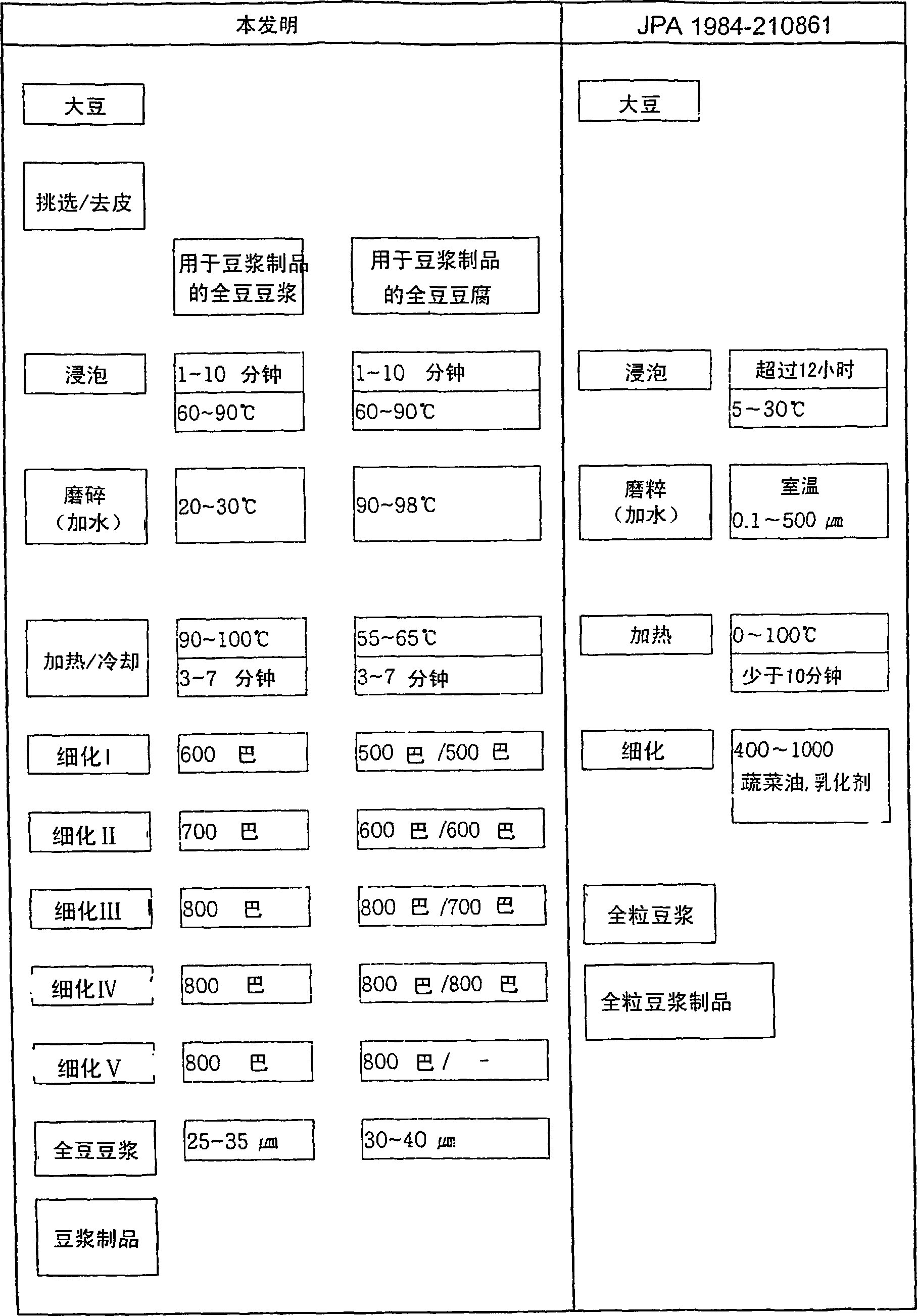

Process for the preparation of whole soybean milk and curd comprising multiple steps of ultra high-pressure homogenization of soybean

An ultra-high pressure and homogenization technology, applied in ultra-high pressure food processing, food homogenization, food preparation, etc., can solve the problems of low production volume, unsatisfactory tofu taste, insufficient homogenization and refinement of soybean milk particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

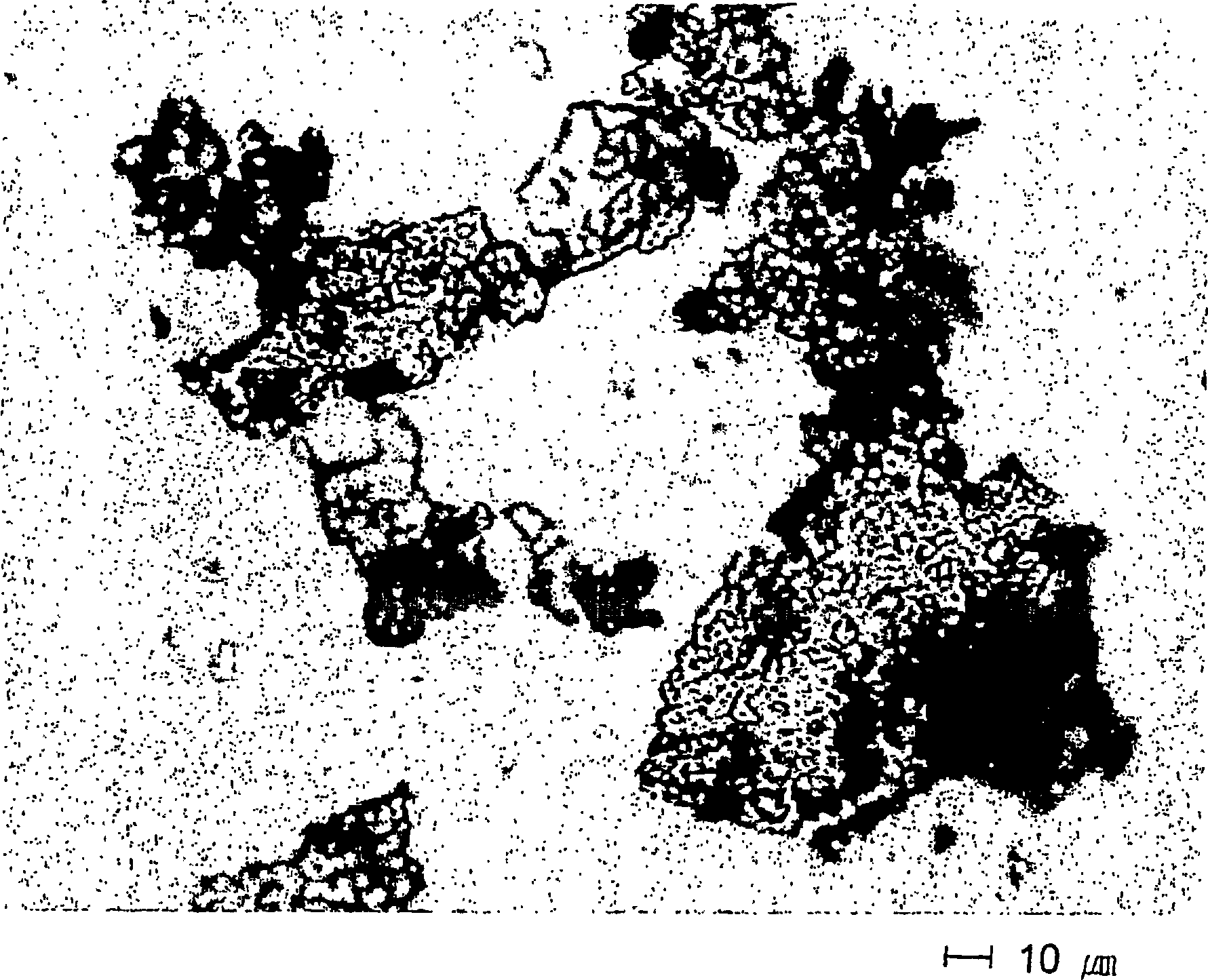

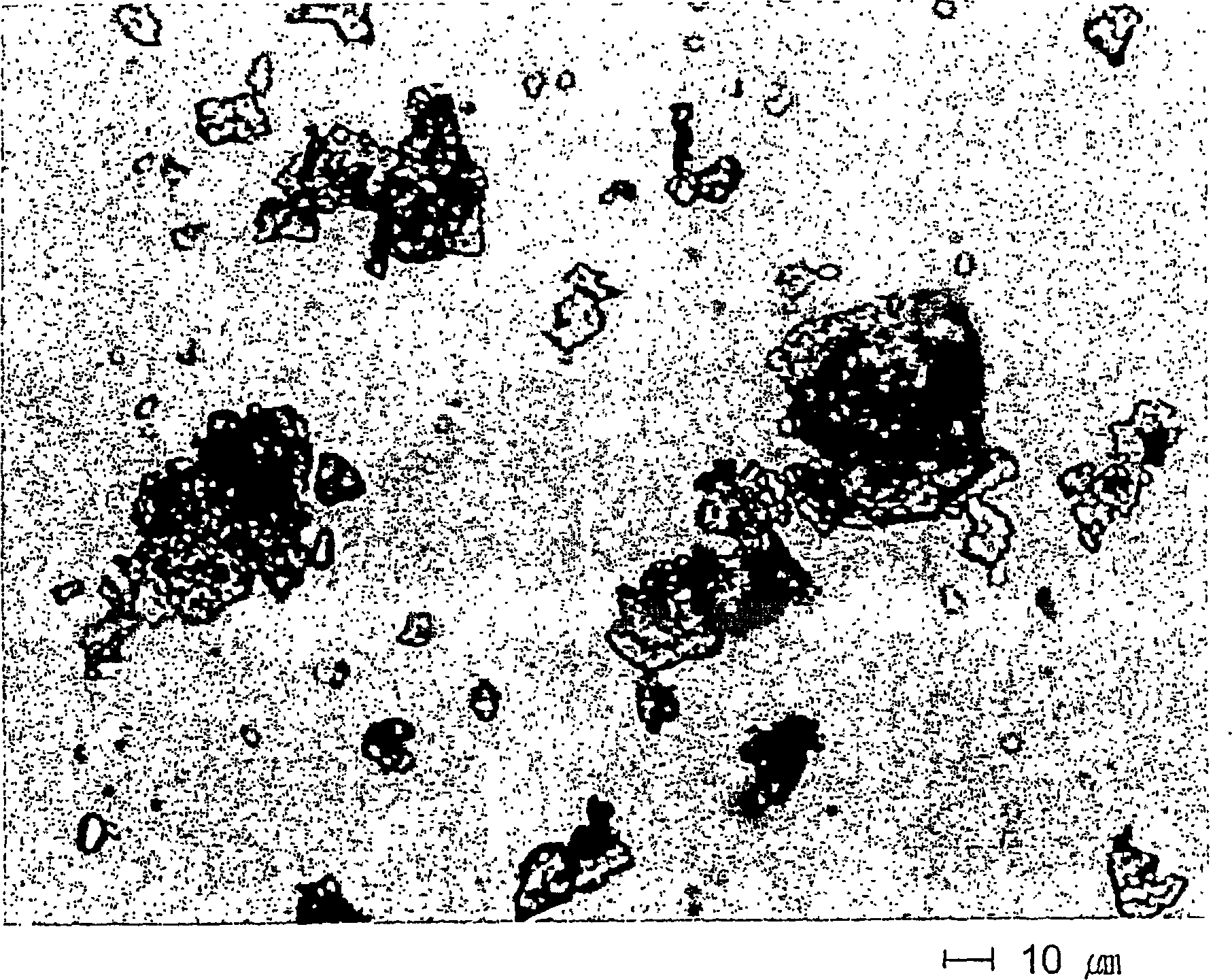

[0047] Choose whole bean soybeans, which are dried and dehulled by the grinding method. 100 kg of peeled beans are soaked in water at 75°C for 5 minutes. Drain the soaking water to remove impurities. The soaked soybeans are conveyed to a grinder and ground with stirring while adding 770 kg of water at 25°C. The obtained soybean juice was heated at 98° C. for 5 minutes in a sterilizing chamber, and then cooled to 90° C. The ground soybean juice is thinned using an ultra-high pressure thinning process including five thinning steps. Specifically, the refining pressure applied to the milled juice was 600 bar in the first step, 700 bar in the second step, and 800 bar in the third step, and then the juice was cooled to 85° C. in a cooler. Subsequently, a refining pressure of 800 bar is applied to the juice in the fourth step, and a pressure of 800 bar is applied in the fifth step to obtain whole bean soymilk. The average particle size of soybean particles of this whole bean soymi...

example 2

[0051] 120 kg of whole beans are soaked in water at 85°C for 10 minutes. Drain the soaking water to remove impurities. The soaked soybeans were sent to a grinder and ground with stirring, while adding 786 kg of water at 98°C and 230 g of sodium bicarbonate. The resulting soy milk is cooled to 60°C in a cooling chamber and then thinned using an ultra-high pressure thinning process consisting of four thinning steps: a pressure of 500 bar is applied in the first step and a pressure of 800 bar is applied in the second step , the third step applies a pressure of 800 bars, and the fourth step applies a pressure of 800 bars, and then obtains whole bean soy milk, the average particle size of soybean particles of this whole bean soy milk is 33 μm, the viscosity is 50 cps, and the solid content is 11% .

[0052] 0.05% of fatty acid sugar ester as an emulsifier and additives such as sugars and flavors were added to the whole soybean milk thus obtained. The resulting mixture was steril...

example 3

[0054] Whole beans are selected, dried and dehulled by grinding. 80 kg of peeled beans were soaked in water at 75°C for 5 minutes. Drain the soaking water to remove impurities. The soaked soybeans are conveyed to a grinder and ground with stirring while adding 790 kg of water at 96°C. The obtained soybean juice was kept for 7 minutes to remove soybean odor generated by lipoxygenase. The resulting soybean milk was thinned using an ultra-high pressure thinning process comprising five thinning steps: applying a pressure of 500 bar in the first step, 600 bar in the second step, 800 bar in the third step, and 800 bar in the fourth step. 800 bar, 800 bar in the fifth step, so as to obtain whole soy milk, the average particle size of soybean particles in this whole soy milk is 32 μm, the viscosity is 120 cps, and the solid content is 8.2%.

[0055] The whole bean soymilk obtained in this way is immediately sent to the tofu production line and packed into a coagulation tank at 82°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com