Drive system for a vehicle moving along a trackway, particularly a magnetic levitation train

A technology of maglev trains and vehicles, applied in the field of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

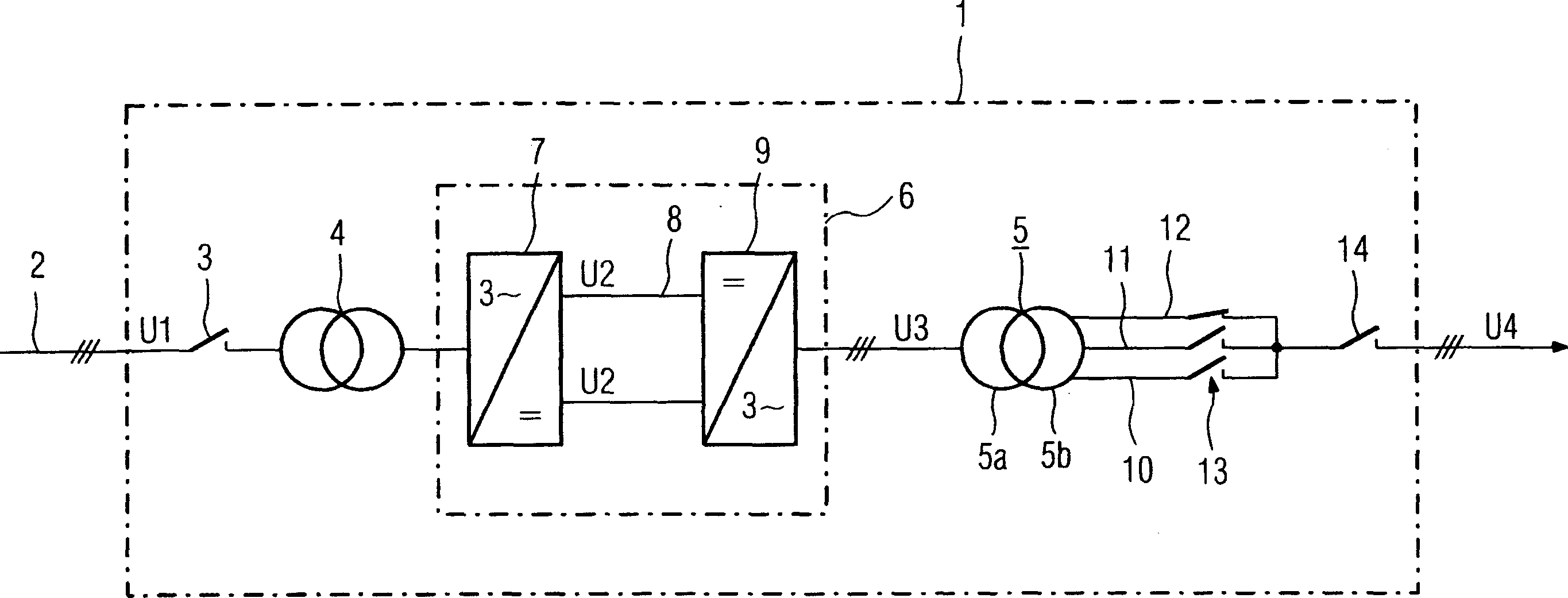

[0011] The drive belongs to a magnetic levitation train (not shown) that moves along the running track and consists of a linear electric motor whose stator extends along the running track and is subdivided into stator segments. The individual stator segments can be connected temporally sequentially to the three-phase output AC voltage U4 of the output transformer 5 (primary winding 5 a, secondary winding 5 b). The output AC voltage U4 is provided by the conversion unit 1, and the three-phase power grid 2 with a medium voltage level supplies power for the conversion unit.

[0012] The conversion unit 1 comprises an input switch 3 connected to the supply network 2 (voltage U1 ), which is connected upstream of an input transformer 4 . Between the input transformer 4 and the output transformer 5 is a converter 6 .

[0013] The converter 6 consists of a rectifier 7 for generating an intermediate circuit DC voltage U2, an intermediate circuit 8 and an inverter 9, wherein the invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com