Cast Al-Si alloy

A technology for casting aluminum-silicon alloys and impurities, which is applied in the field of casting aluminum-silicon alloys, can solve problems such as poor mechanical properties of Al-Si alloys and unheatable die-cast aluminum alloys, and achieve the effects of improving mechanical properties, reducing mold costs and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

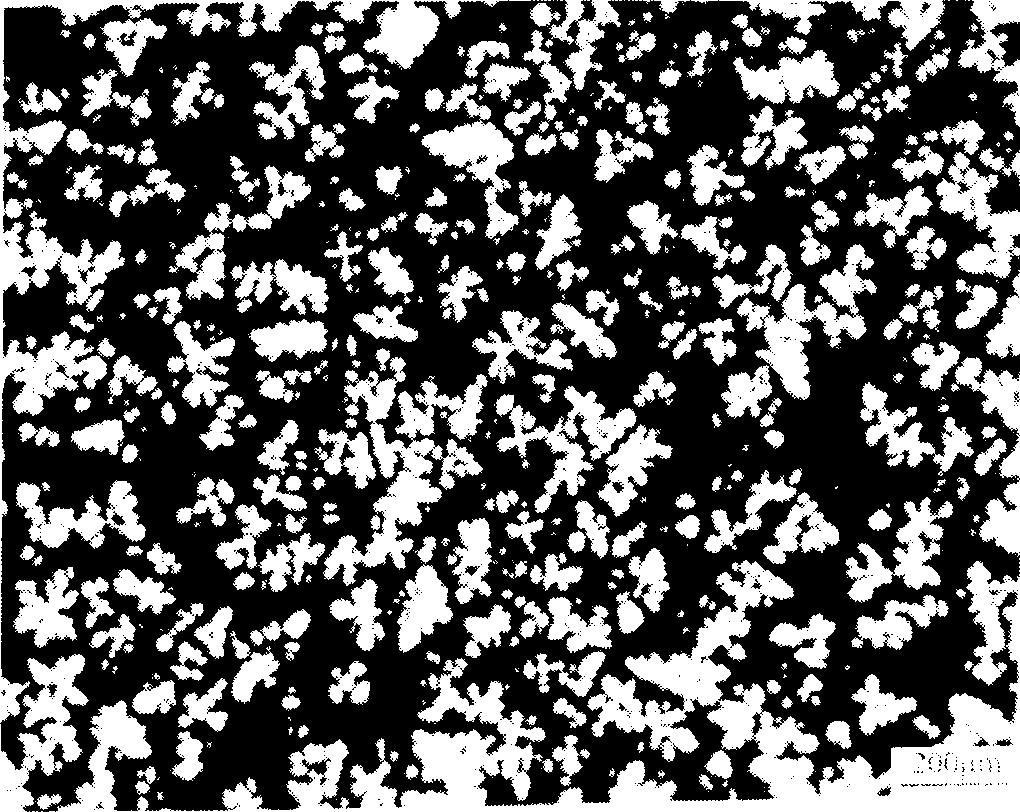

Image

Examples

Embodiment 1

[0015] A cast aluminum-silicon alloy, the composition and ratio of which are as follows: Si: 11.0%-13.5%; Mg: 0.15%-0.55%; Sr: 0.015%-0.080%; B: 0.010%-0.050%; Cu: <0.20 %; Fe: <0.20%; Zn: <0.10%; Mn: <0.10%; Ti: <0.10%; other impurities individually <0.05%, total <0.15%; In this embodiment, Si may be 11.0%, 12% or 13.5%; Mg may be 0.15%, 0.35% or 0.55%; Sr may be 0.015%, 0.045% or 0.080%; B may be 0.010%, 0.030% or 0.050%; Cu: <0.20%, preferably 0.18% or 0.02%; Fe: <0.20%, preferably 0.19% or 0.01%; Zn: <0.10%, preferably 0.19% or 0.015%; Mn: <0.10%, preferably 0.16% or 0.005% %; Ti: <0.10%, can be 0.09% or 0.005%; Mn: <0.10%, can be 0.09% or 0.01%; other impurities individually <0.05%, total <0.15%; balance Al.

Embodiment 2

[0017] The indoor temperature is 20°C and the relative humidity is 20%.

[0018] The alloy formulated according to the chemical composition requirements of the AlSi alloy was melted at 760°C and refined at 730°C with degassing and slag removal, adding Al-10Sr master alloy (market purchase: Nanjing Yunhai Special Metal Co., Ltd.) and Al-3B master alloy ( Purchased from the market: Xuzhou Huayuan Special Material Factory) for Sr+B joint melt treatment, poured into the standard tensile test bar mold (cast iron type, preheating temperature 250-300°C) at 690-710°C, and produced 10 pieces Single-cast test bars (nominal diameter 12mm), 5 of which were heat treated according to the A356 alloy T6 procedure (solution temperature 535±5°C, solution time 6 hours; aging temperature 155±5°C, solution time 3 hours). Tensile experiments were carried out on a WJ-10 mechanical universal testing machine. The chemical composition of the alloy was determined by ICP direct reading spectrometer. Th...

Embodiment 3

[0023] The indoor temperature is 25°C and the relative humidity is 40%.

[0024] The production and measurement process of 10 test rods are the same as in Example 2.

[0025] main chemical composition

[0026] Si: 12.57%; Mg: 0.30%; Sr: 0.045%; B: 0.026%; Fe: 0.18%; Cu: 0.13%; Zn: 0.06%; Mn: 0.07%; Ti: 0.04%; Require.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com