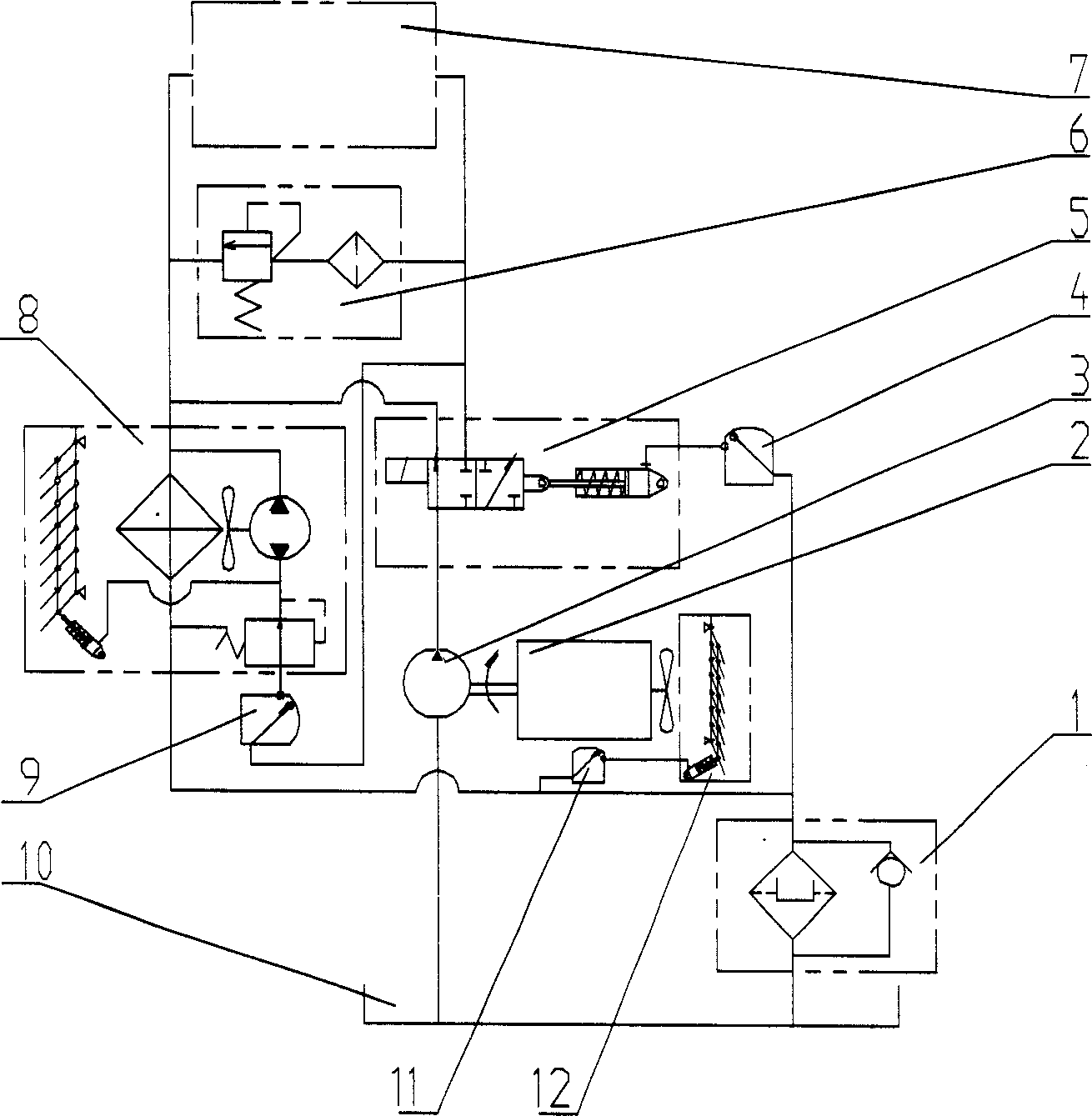

Energy-saving control loop of hydraulic system

A hydraulic system and energy-saving control technology, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve problems such as energy waste, achieve low cost, reduce heat dissipation, and reduce production and usage costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] First, the engine (2) hydraulic pump (3) is connected as a whole and fixed on the base frame of the mechanical equipment, the manual rotary valve (4) is fixed on the operating table of the mechanical equipment, the fuel tank (10), the valve block assembly (5) , Radiator (8), overflow valve (6) are also installed on the base frame of mechanical equipment, ventilation window (12) is installed on the front end of engine (2) cooling water tank, return oil filter (1), temperature control The valve (9) is installed in the fuel tank (10), and the temperature control valve 2 (11) is connected to the engine coolant outflow pipeline; the fuel tank (10), hydraulic pump (3), valve block assembly (5), hydraulic The connection between the main oil circuit (7) and the oil outlet of the valve block assembly (5), the temperature control valve (9), and the high-pressure pipeline between the radiator (8); 8), the connection between the oil return filter (1) and the pipeline between the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com