Double-walled continuous cooling system

A cooling system and cooling technology, applied in coolers, cooling fluid circulation devices, refrigerated rooms, etc., can solve the problems of high cooling efficiency, unfavorable cooling speed, slow cooling speed, etc., to reduce the generation of frost and achieve good cooling capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the double-walled continuous cooling system (hereinafter referred to as the cooling system) of the present invention will be described below.

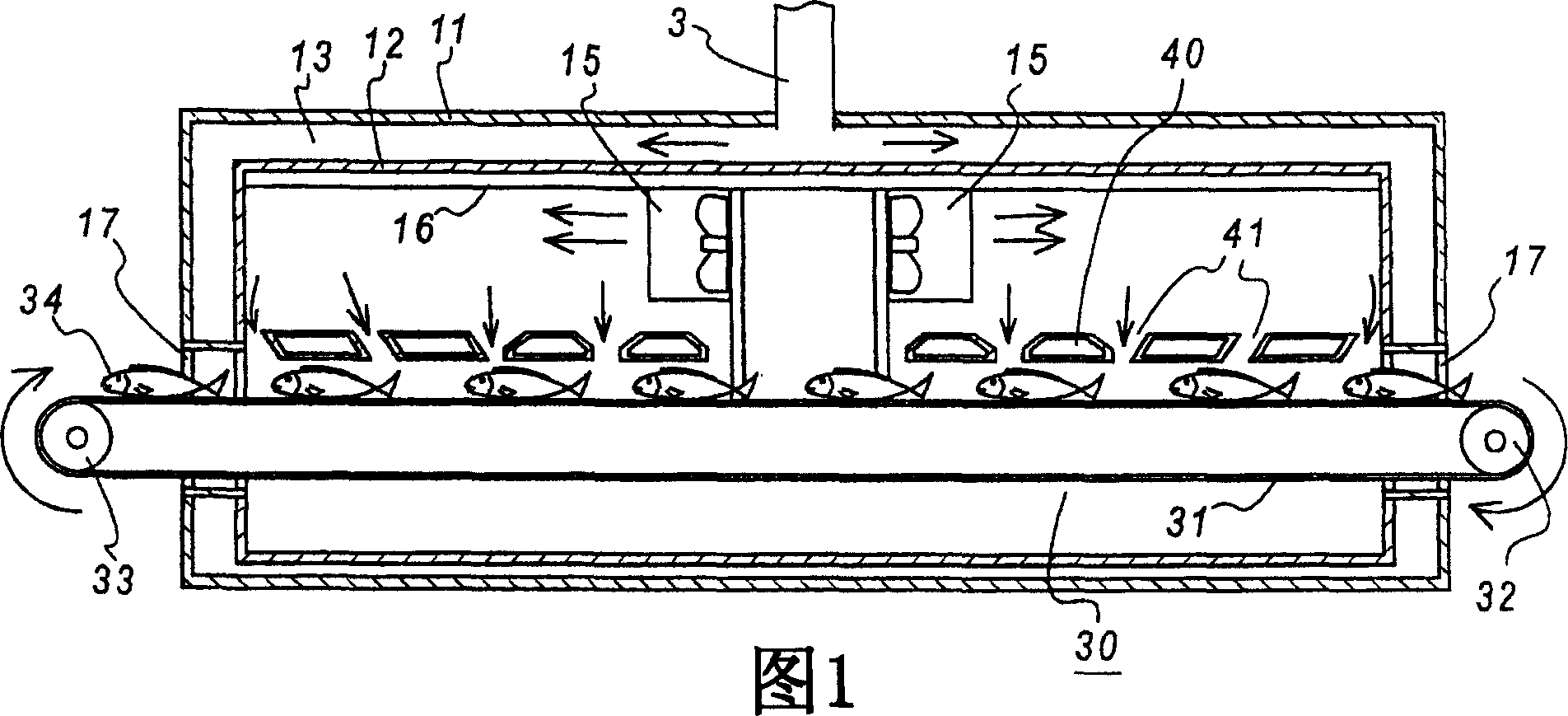

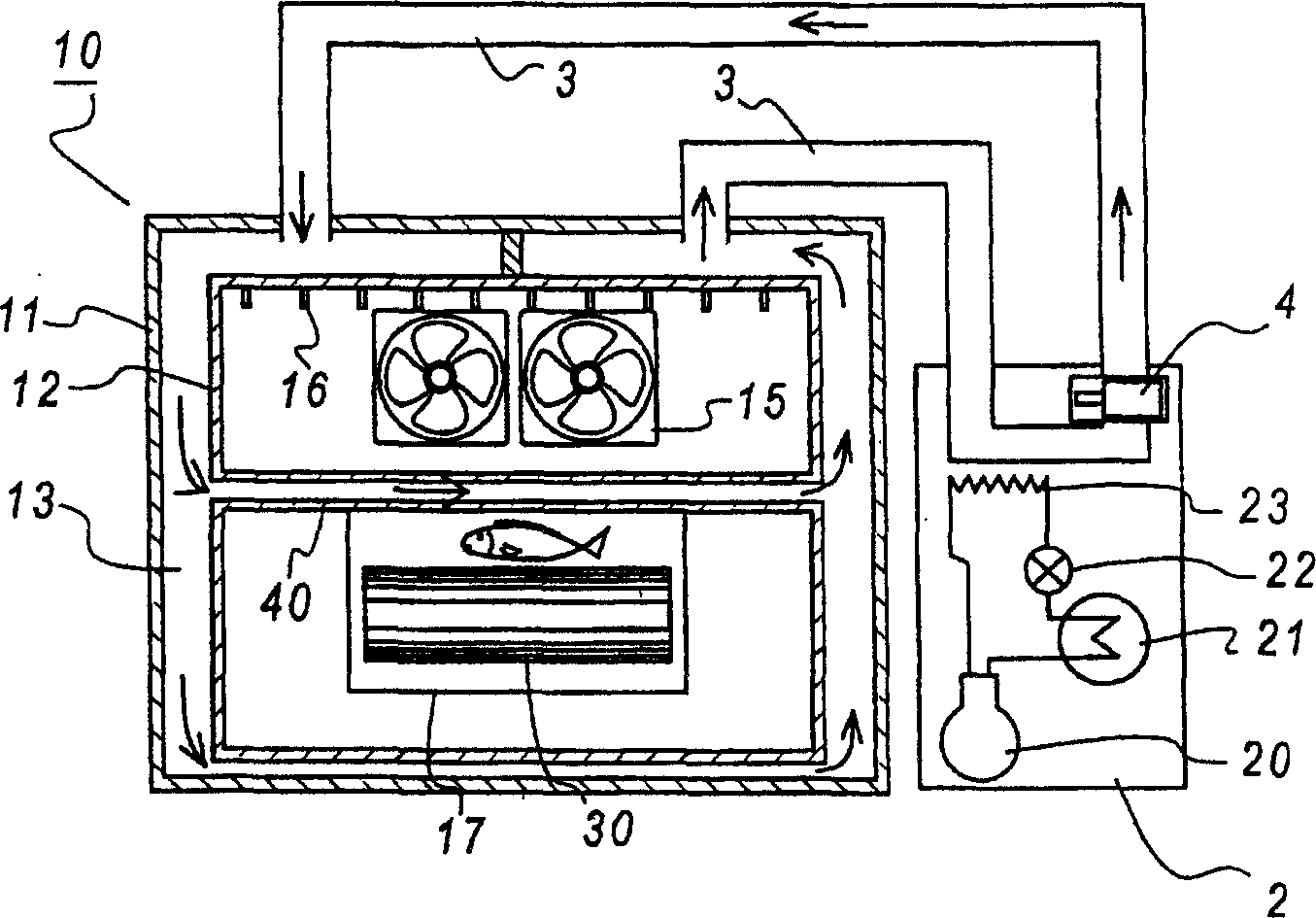

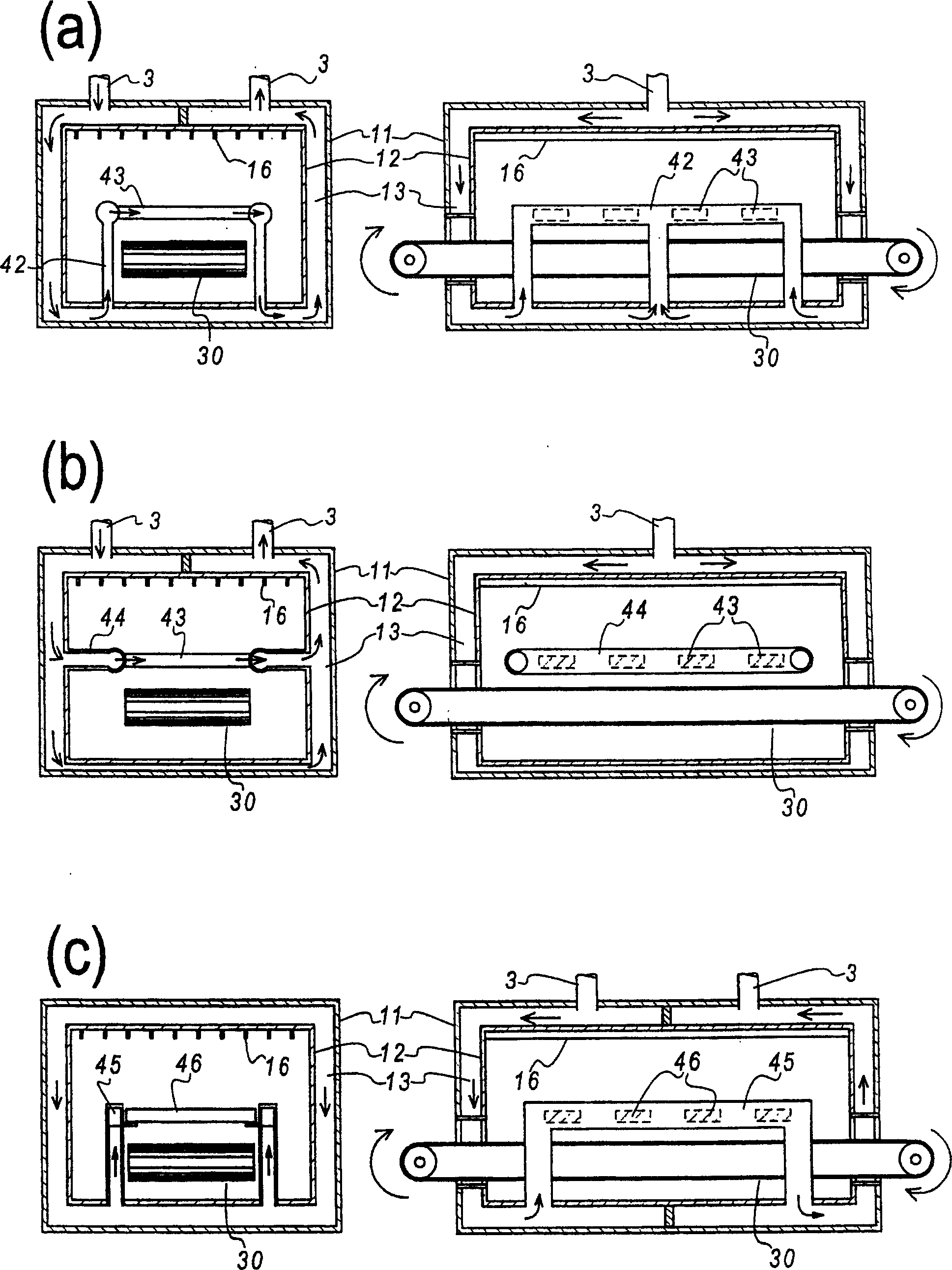

[0027] Fig. 1 is a side sectional view of the cooling system involved in the present embodiment, figure 2 is a front cross-sectional view of the cooling system according to this embodiment.

[0028] Referring first to Figure 1 and figure 2 The overall configuration of the cooling system 1 will now be described.

[0029] Such as figure 2 As shown, the cooling system 1 is roughly composed of a low-temperature medium generating device 2 and a casing 10 . Inside the low-temperature medium generating device 2 , the refrigerant passing through the compressor 20 and the condenser 21 passes through the expansion valve 22 and absorbs heat in the evaporator 23 to cool the cooling medium flowing inside the medium pipeline 3 . As the cooling medium, dry air, salt water, cold water, etc. can be used, but there are also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com