Oxygen-absorbing resin composition

An oxygen-absorbing resin and composition technology, applied in the field of packaging materials, can solve problems such as the inability to obtain gas barrier properties, and achieve the effects of inhibiting oxidative deterioration, excellent oxygen-absorbing performance, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

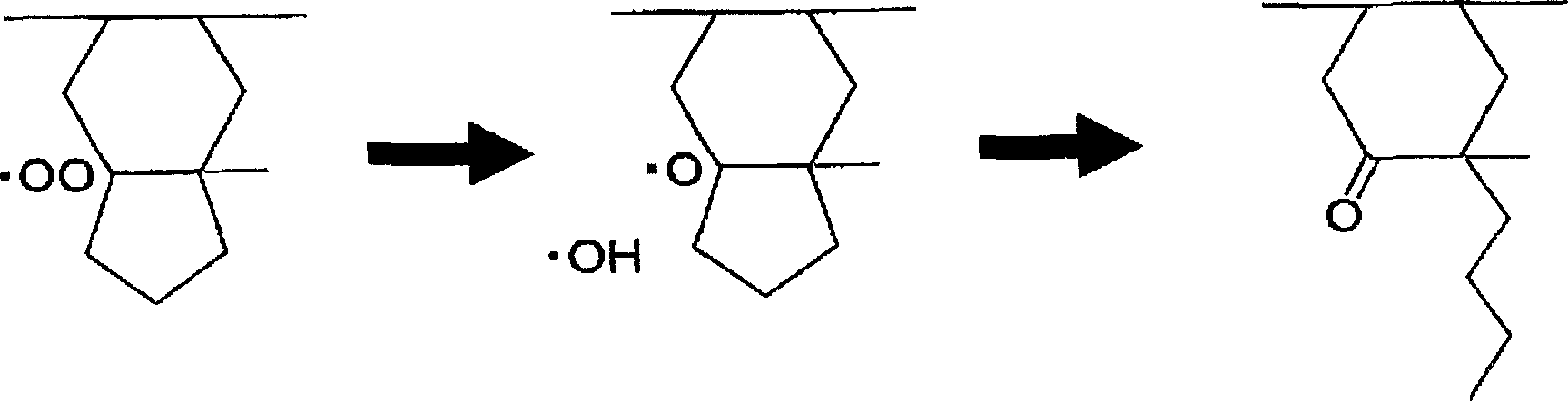

Method used

Image

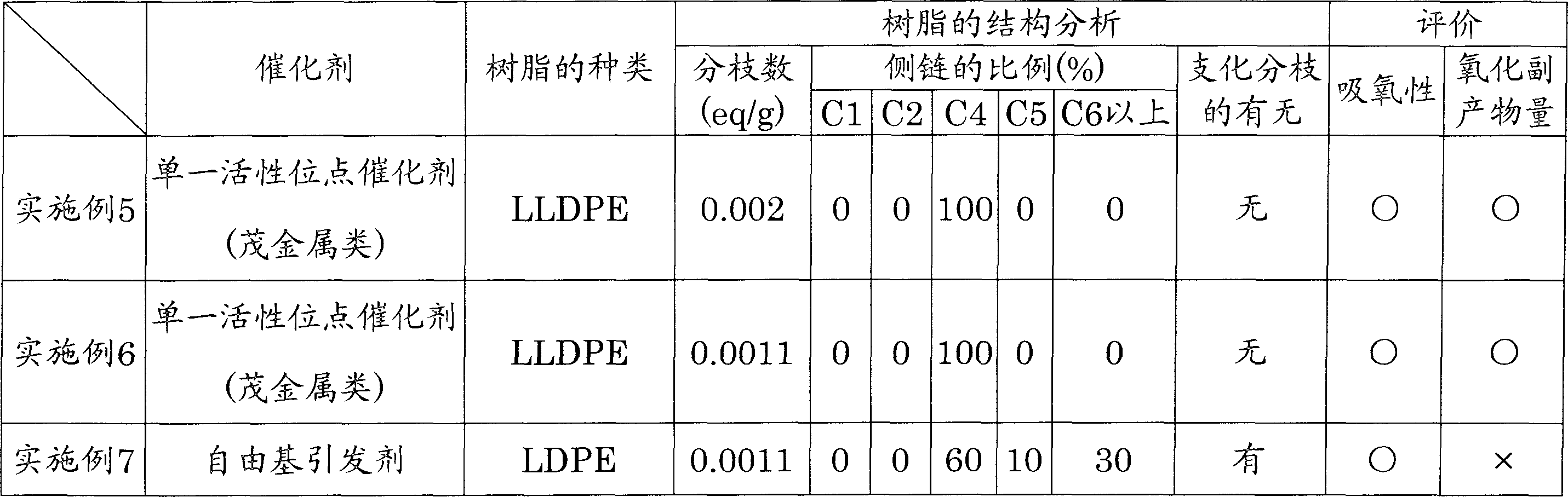

Examples

Embodiment 1

[0109] In low-density polyethylene resin (JB221R, produced by Nippon Polyorefin Co., Ltd.), 5.0% by weight of hydrogenated styrene-isoprene-styrene triblock copolymer resin (Hibura-7125, produced by Co., Ltd.) was mixed. Production, the carbon-carbon double bond content in the resin is 2.0×10 -4 eq / g) and an oxidation catalyst, the above-mentioned method was used to make resin composition pellets, and the oxygen absorption amount (cc / g) of the resin composition was calculated. The results are shown in Table 1.

[0110] In addition, using the pellets, a multi-layer bottle was produced by the above-mentioned method, and the evaluation of the oxygen barrier property and the measurement of the hunter color b value were performed. The results are shown in Table 2.

Embodiment 2

[0112] In addition to replacing hydrogenated styrene-isoprene-styrene triblock copolymer resin, hydrogenated styrene-butadiene-styrene triblock copolymer resin (Taftec P2000, Asahi Kasei Chemical Co., Ltd.) Production, the carbon-carbon double bond content in the resin is 1.9×10 -3 Except eq / g), resin composition pellets were produced in the same manner as in Example 1, and the oxygen absorption amount (cc / g) of the resin composition was calculated. The results are shown in Table 1.

[0113] In addition, using the pellets, a multi-layer bottle was produced by the above-mentioned method, and the evaluation of the oxygen barrier property and the measurement of the hunter color b value were performed. The results are shown in Table 2.

Embodiment 3

[0115] In addition to replacing the hydrogenated styrene-isoprene-styrene triblock copolymer resin, a 2.5% by weight hydrogenated styrene-butadiene-styrene triblock copolymer resin (Taftec P2000, Asahi Kasei Chemikarzu Co., Ltd., the carbon-carbon double bond content in the resin is 1.9×10 -3 eq / g) and 2.5% by weight of hydrogenated styrene-butadiene copolymer resin (Dainaron 1320P, produced by (strain) JSR, the carbon-carbon double bond content in this resin is 2.4 × 10 -5 Except eq / g), resin composition pellets were produced in the same manner as in Example 1, and the oxygen absorption amount (cc / g) of the resin composition was calculated. The results are shown in Table 1.

[0116] In addition, using the pellets, a multi-layer bottle was produced by the above-mentioned method, and the evaluation of the oxygen barrier property and the measurement of the hunter color b value were performed. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com