Glass needle-tube former of pre-encapsulated injector

A technology for syringes and glass needles, which is applied in the field of forming glass syringes for prefilled syringes. It can solve the problems of imminent localization of prefilled syringes, restrictions on the development of the pharmaceutical industry, and capital outflows, achieving significant economic and social benefits. Automated operation and good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

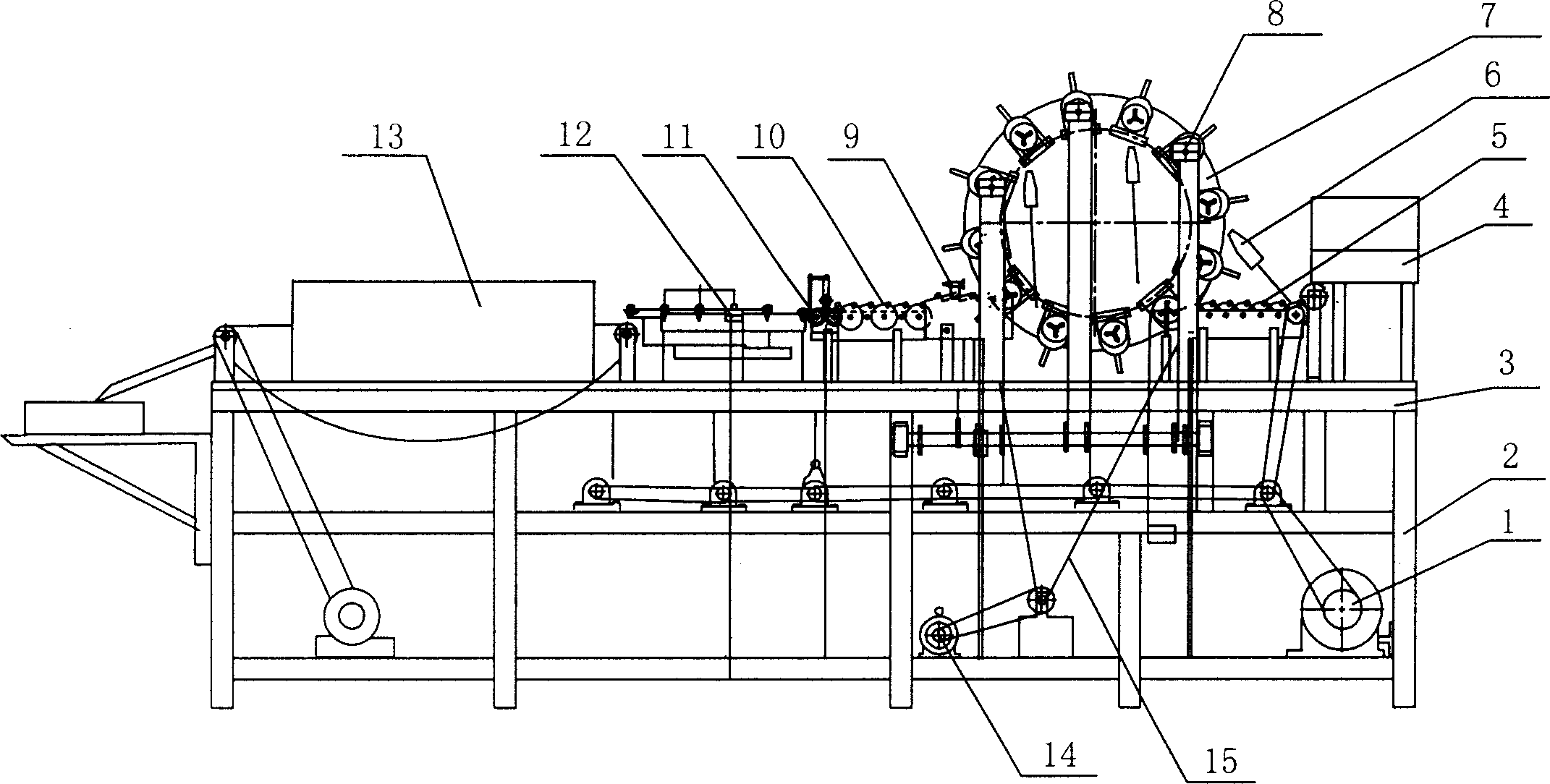

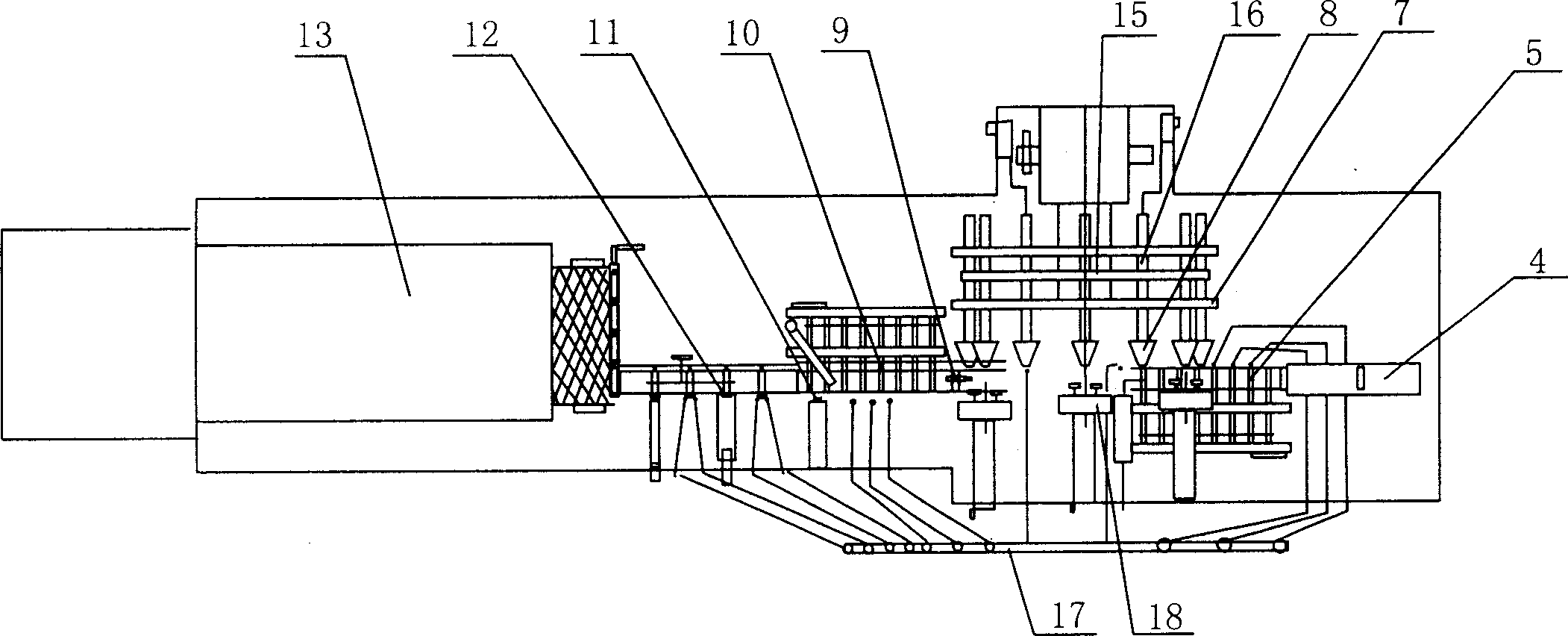

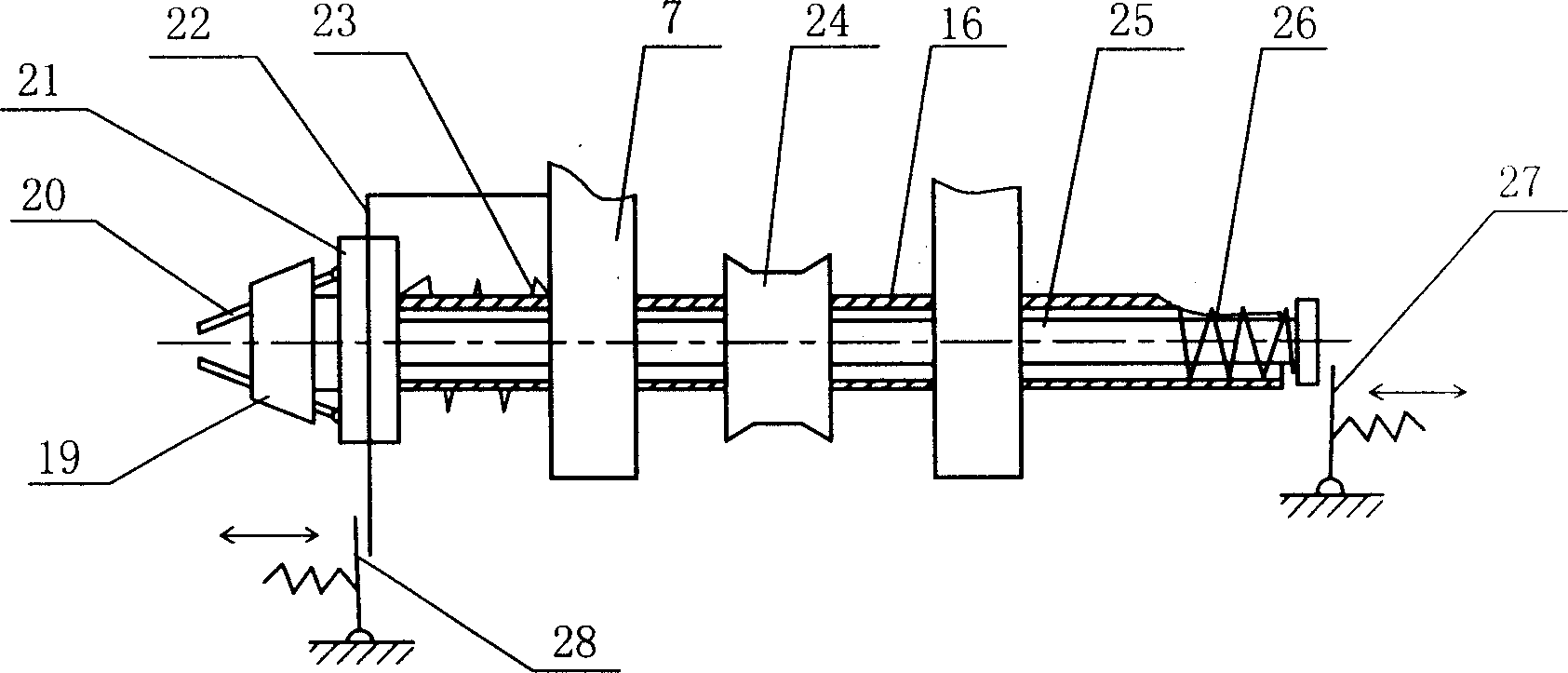

[0032] Such as figure 1 , 2 , 8 and Figure 9As shown, the glass syringe molding machine for prefilled syringes of the present invention sequentially includes a glass tube input mechanism 5, a head forming mechanism, a tail flanging mechanism 11 and an annealing furnace 13, and a glass tube delivery mechanism is arranged between each mechanism. Mechanism, the glass tube conveying mechanism is composed of notched disc wheels 46 distributed in dislocation, and the notched disc wheels are respectively fixed on the rotating shafts in the same direction and at the same speed. The glass tube input mechanism includes glass tube storage bucket 49 and notch input shaft 47, glass tube storage bucket 49 The lower mouthpiece 48 of the nozzle corresponds to the notch input shaft 47, and the notch input shaft 47 corresponds to the notch sheet wheel of the subseq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com