A kind of production method of low temperature seamless steel pipe for liquefied natural gas

A technology of liquefied natural gas and seamless steel pipes, applied in temperature control, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of welding bead tracking and feedback system research that have not yet started, and achieve low cost, simple production process, and finished products high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

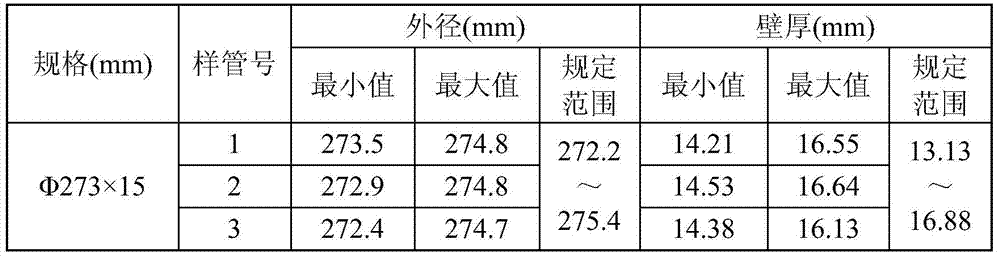

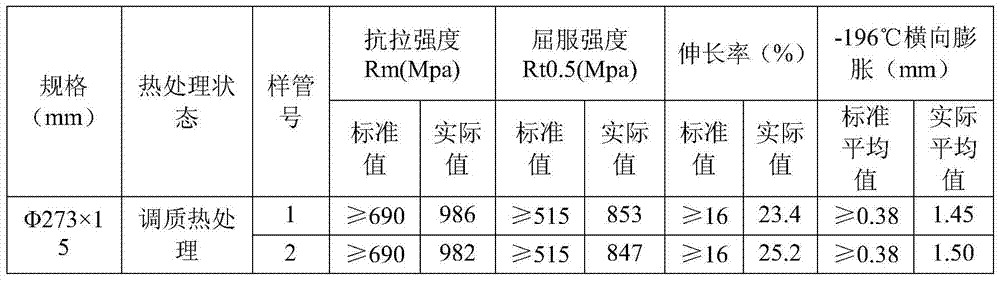

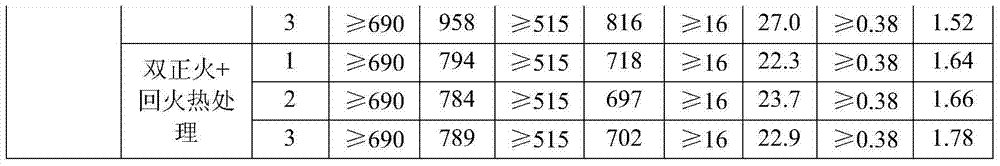

[0029] In this embodiment, the outer diameter is mainly Φ273 mm, the outer diameter tolerance is (-0.8, +2.4) mm; the wall thickness is 15 mm, the wall thickness tolerance is ±12.5%, the length is ≥ 6 mm, the ellipticity is less than or equal to 1.5%, and the wall thickness is not Cr.8 steel low-temperature seamless steel pipes for liquefied natural gas (LNG) with uniformity ≤ 2.8mm.

[0030] The process flow is as follows:

[0031] Φ280mmVD continuous casting billet → billet cutting → billet heating → piercing → 340mmMPM continuous rolling mill rolling tube billet → hot sawing head and tail → cooling → straightening → finishing → size and surface quality inspection → packaging and storage;

[0032] Wherein, the billet heating is divided into a preheating section, a heating section and a soaking section. The preheating section is preheating ≥ 100min at a temperature of 580-795°C; the heating section is divided into heating section 1, heating section 2, and heating section 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com