High-rigidity universal milling head with automatic rotating B shaft

A universal milling head, automatic rotation technology, applied in the driving device, metal processing mechanical parts, metal processing equipment and other directions, can solve the problems of the second type of universal milling head is expensive, prone to safety hazards, and the B axis needs to be manually adjusted. , to achieve the effect of large torque, eliminating safety hazards and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

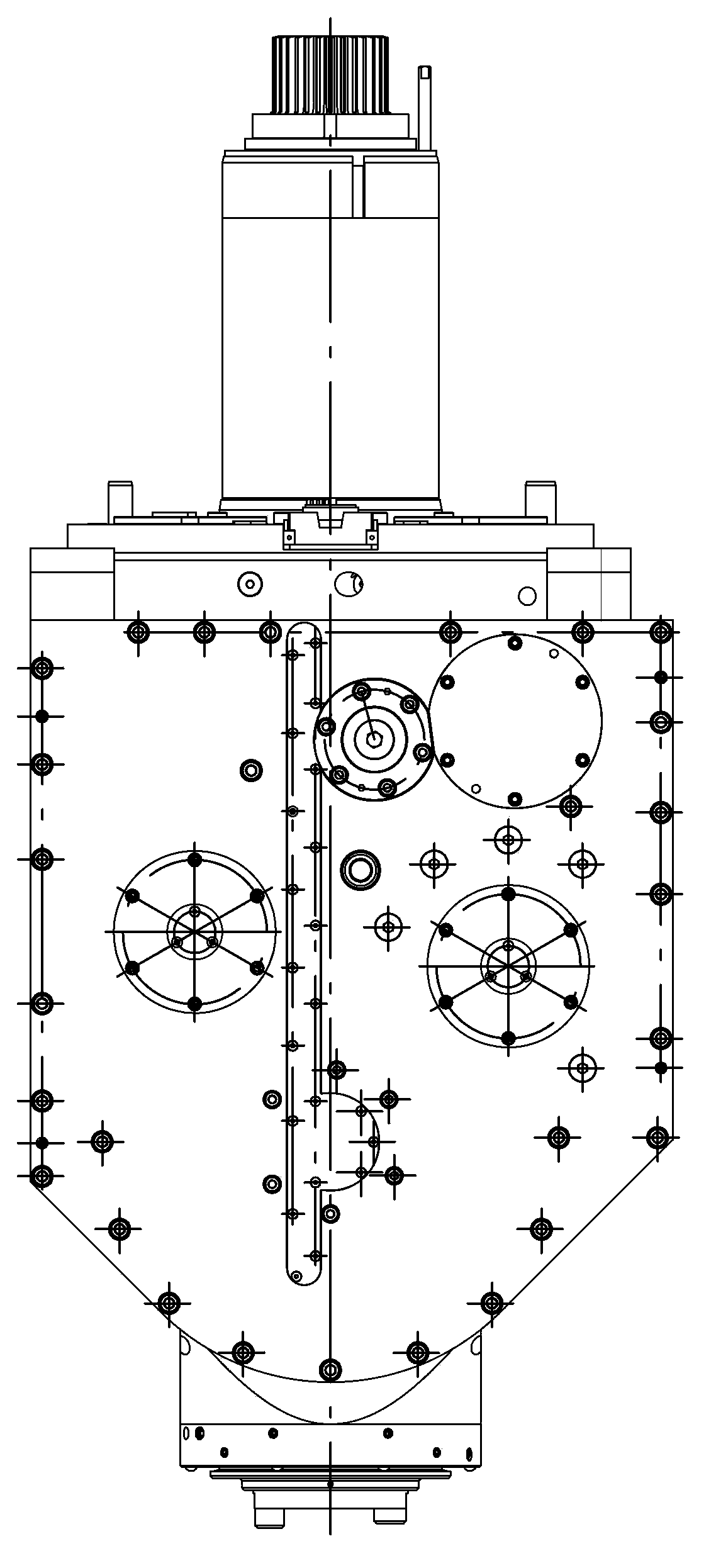

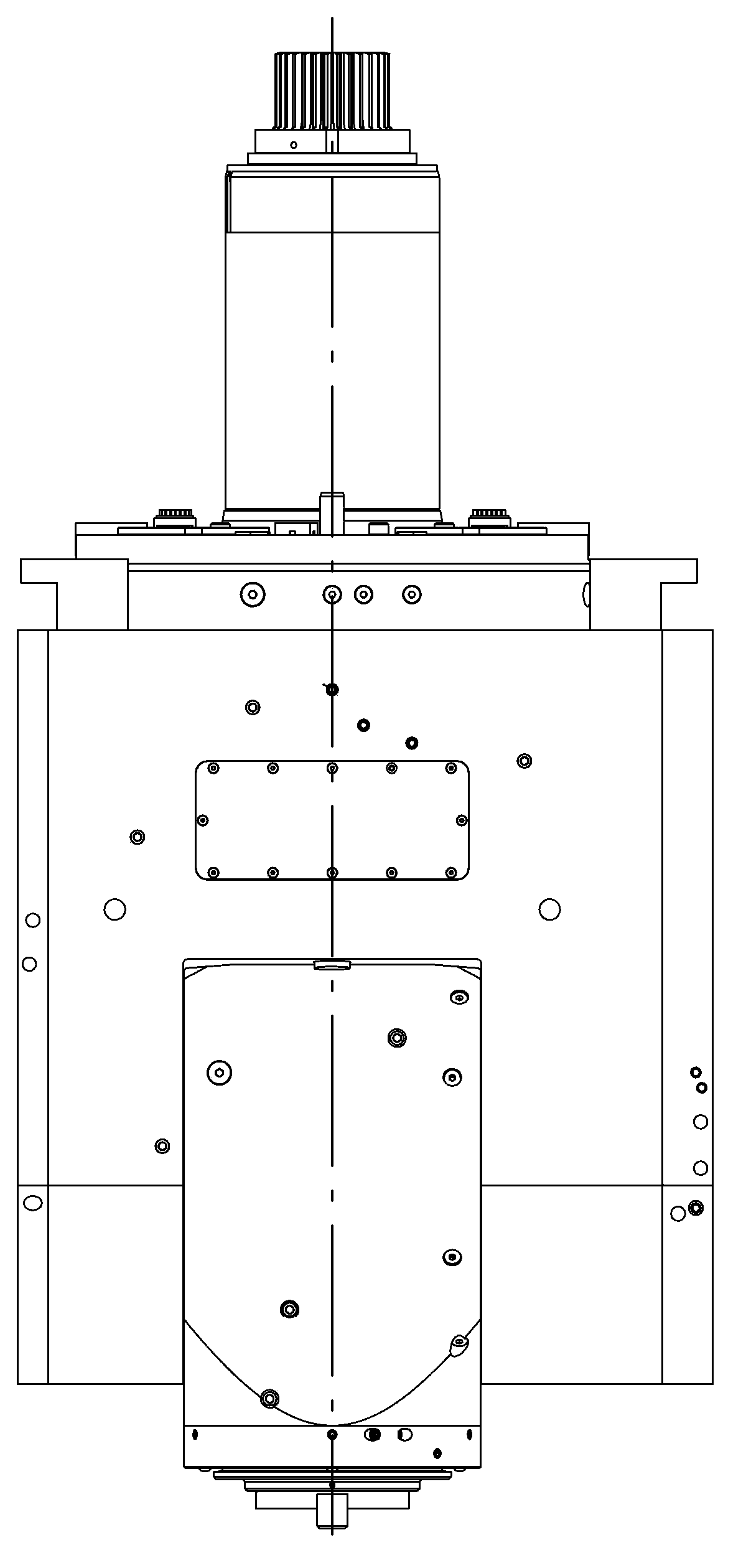

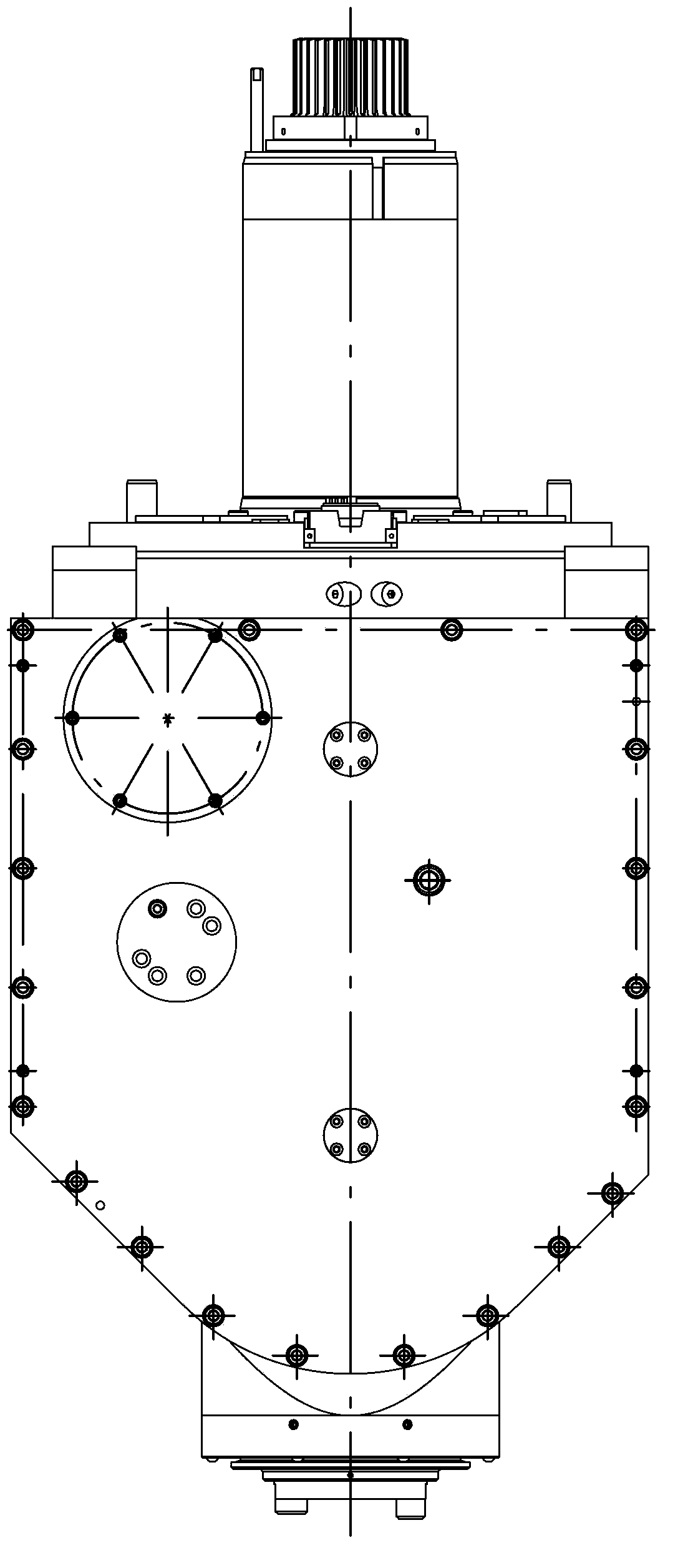

[0024] Highly rigid universal milling head with automatic rotation of the B axis, see Figure 1a-1c , The shell of the universal milling head is hollow, and the tool spindle is installed in the middle of the lower part. It is characterized in that the milling power gear mechanism and the B-axis power gear mechanism are installed on both sides of the universal milling head shell.

[0025] see Figure 2a-Figure 2d , hide the internal structure diagram of the universal milling head shell for the universal milling head. as the picture shows, Figure 2a The B-axis power gear mechanism is installed on the left side, and the milling power gear mechanism is installed on the right side. The Siemens built-in motor 1 is installed in the universal milling head shell, and is the power source of the B-axis power gear mechanism. Its output end is connected to the planetary gear reducer 2, the reduction ratio is i=22, and the output end of the reducer is a flange output. , connecting the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com