Hydraulic system oil tank liquid low-pressure supercharging device

A technology of hydraulic system and booster device, which is applied in fluid pressure converters, mechanical equipment, etc., can solve the problems of hydraulic pump oil suction noise, insufficient oil suction, loud noise, etc., and achieve the advantages of reducing oil suction noise, simplifying structure, and convenient monitoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

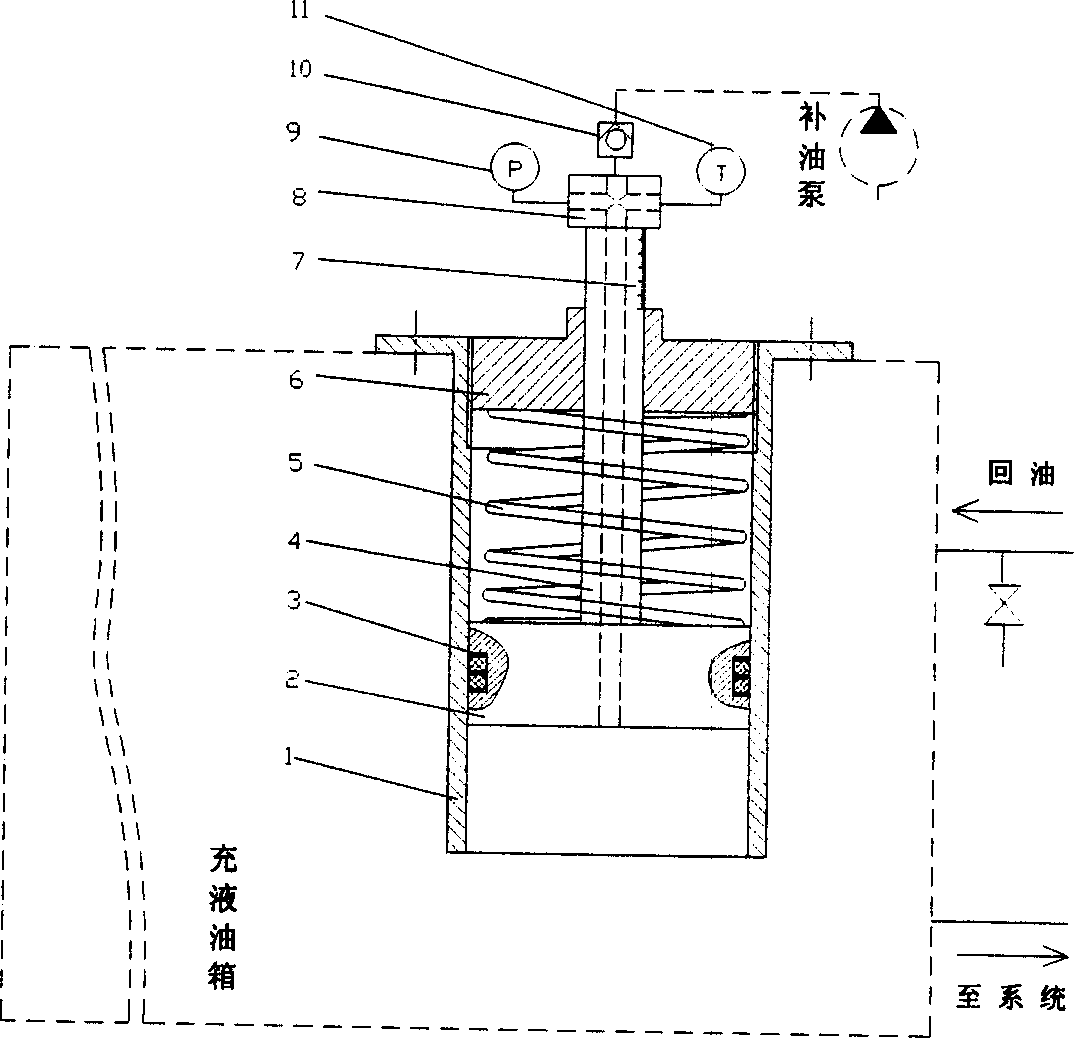

[0012] The supercharging device consists of a supercharging cylinder 1, a supercharging piston 2, a piston seal ring 3, a hollow piston rod 4, a pressure setting spring 5, a pressure regulating cover 6, a leak detection scale 7, and three combinations of oil injection, pressure measurement and temperature measurement. Pass 8, pressure gauge 9, one-way valve 10, temperature gauge 11 composition.

[0013] During implementation, the supercharging device is installed on the liquid-filled oil tank, and the supercharging piston 2 isolates the oil from the atmosphere. After the oil tank and system with the supercharging device are installed, refuel the liquid-filled oil tank and the hydraulic system At this time, the maximum pressure of the oil filter truck is slightly higher than the required filling pressure of the fuel tank (it is required that the minimum oil discharge pressure of the hydraulic system and the pressure resistance of the fuel tank should be higher than the required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com