High-toughness Yakeli light-reflecting film and production thereof

A flexible and acrylic technology, applied in the field of high-flexibility acrylic reflective film and its manufacturing, can solve the problems of difficult large-scale industrial production, low brightness of reflective film, low retroreflection coefficient, etc., to facilitate large-scale industrial production, High reflective intensity and good flexural resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

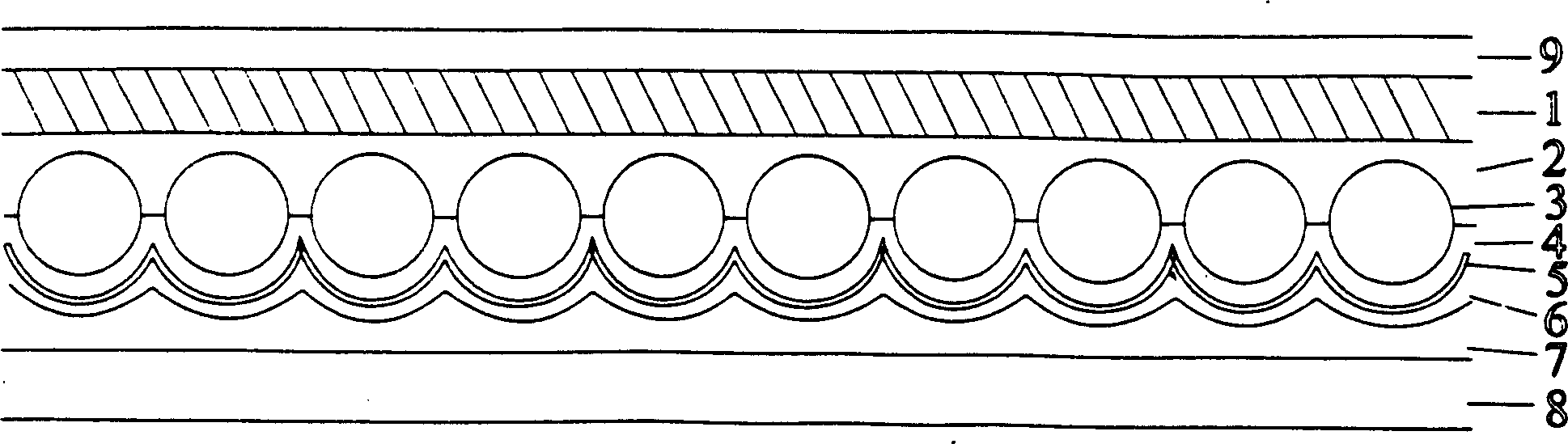

[0014] Such as figure 1 The shown highly flexible acrylic reflective film of the present invention consists of a surface resin layer 1, an adhesive layer 2, a single layer of closely arranged glass bead layer 3, a focusing paint layer 4, a metal reflective layer 5, a metal protective layer 6, a pressing The sensitive adhesive layer 7 and the anti-adhesive layer 8 are compositely bonded, and the surface resin layer 1 is provided with a protective backing layer 9 . The surface resin layer 1 is a transparent resin film with a thickness of 15-70 microns coated with high weather resistance multi-component acrylic resin, unsaturated polyester resin or polyurethane resin, or a mixture of the above materials. The focusing coating 4 is a spherical focusing coating 4 with a thickness of 5-10 microns and concentric with the spherical bottom surface of the glass microspheres 3 . The metal reflective layer 5 has a thickness of 3-5 microns. The metal protective layer 6 has a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com