Production of recombinant human interferon beta

A technology of interferon β and nucleotide sequence, which is applied in the field of efficient production of recombinant human interferon β, and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

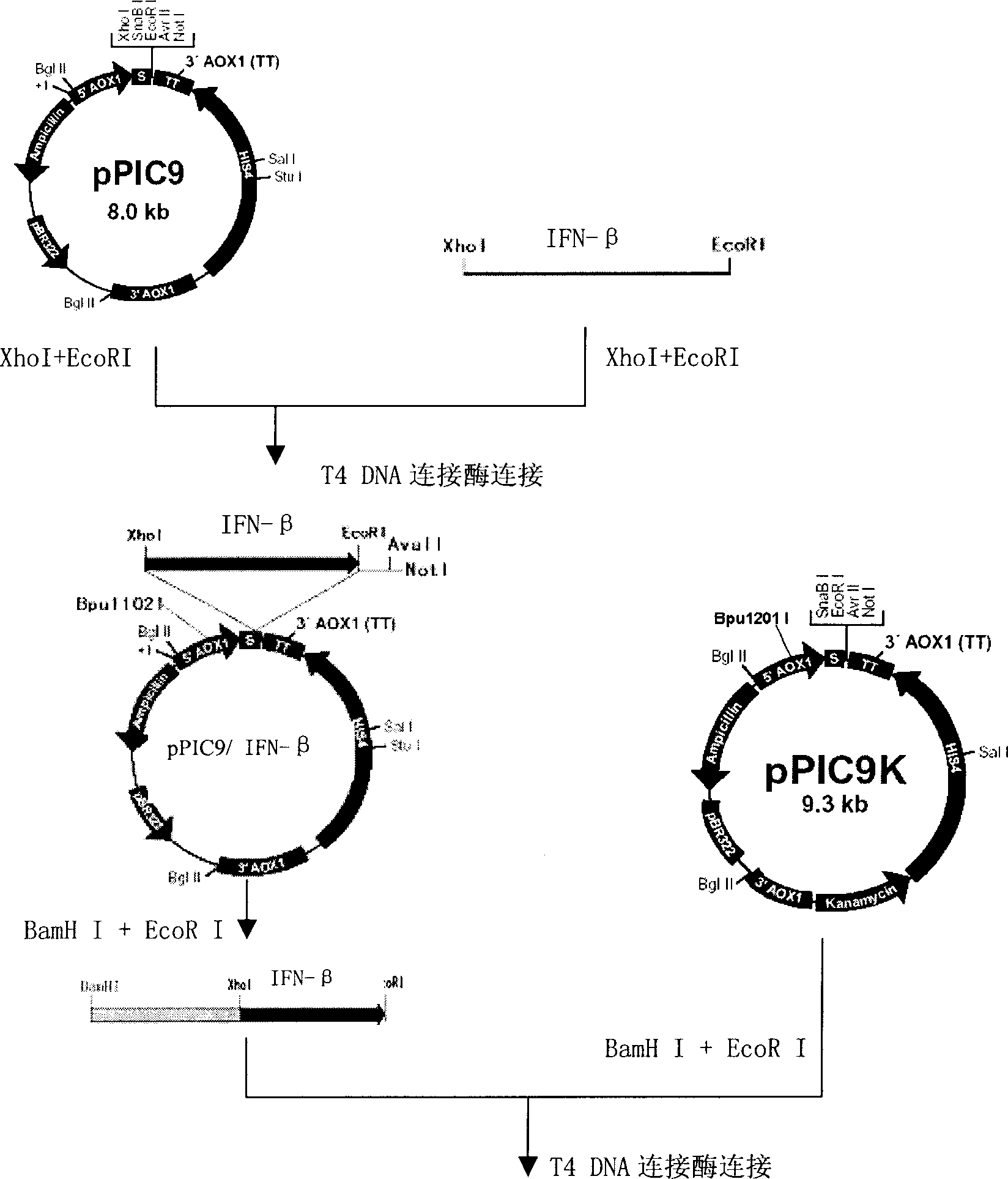

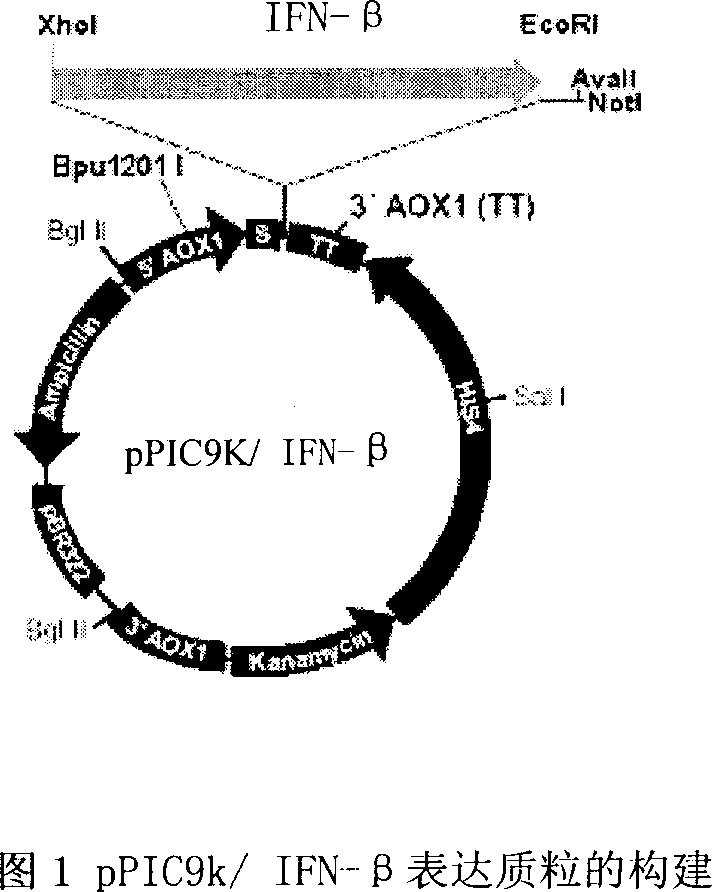

[0064] The construction of embodiment 1 expression plasmid and the acquisition of high expression engineering strain

[0065] According to the natural amino acid sequence of human interferon β, according to the codon preference, under the condition of not changing the amino acid sequence, the target gene sequence of the recombinant human interferon β protein was synthesized, and the gene was cloned into pUC19 and verified by sequencing

[0066] The expression vector construction method is shown in Figure 1. The target human interferon β gene was amplified by PCR, and double-digested with XhoI+EcoRI (MBI, 2*Tango TM , 37°C) PCR product and pPIC9 plasmid (purchased from Invitrogen). The two fragments were ligated with T4 DNA ligase, and the ligated product was transformed into Escherichia coli DH5α (purchased from Promega Company), clones were selected on an LB plate containing ampicillin, a small amount of plasmid was prepared, and screening was performed by double enzyme dige...

Embodiment 2

[0068] Embodiment 2 Induction phase adds different protein protectors to the influence of expression level

[0069] Take a single clone, inoculate it into the BMGY primary seed liquid, and cultivate it for 17-20hr; secondly inoculate it in a 1L Erlenmeyer flask of 250ml BMGY at a ratio of 1:10, culture it for about 4~8hr, put it into the tank for fermentation, pH 5.0, temperature 20°C, DO > 35%, after the dissolved oxygen rises, add 50% glycerol at 10~15 rpm. After the glycerin is exhausted and the dissolved oxygen rises again, use 100% methanol to start induction at speed 1, and gradually increase the speed. In the induction phase, 300ml of CA, Peptone and Tryptone with a concentration of 10% were added to the tank (5L fermenter, 3L fermentation supernatant), and the induction was over for 48hrs. Samples were tested for SDS-PAGE and protein content to determine the best protein protectant for the induction phase.

Embodiment 3

[0070] The influence of different Peptone amounts in the induction stage of embodiment 3 on the expression level

[0071] Take a single clone, inoculate it into the BMGY primary seed liquid, and cultivate it for 17-20hr; secondly inoculate it in a 1L Erlenmeyer flask of 250ml BMGY at a ratio of 1:10, culture it for about 4~8hr, put it into the tank for fermentation, pH 5.0, temperature 20°C, DO > 35%, after the dissolved oxygen rises, add 50% glycerol at 10~15 rpm. After the glycerin is exhausted and the dissolved oxygen rises again, use 100% methanol to start induction at speed 1, and gradually increase the speed. In the induction stage, different volumes of 10% Peptone flow were added to a 5L fermenter (fermentation supernatant 3L), and the induction ended for 48 hours. Samples were tested for SDS-PAGE and protein content to determine the optimal amount of Peptone for the induction phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com