Electric chuck unit

An electric chuck and chuck technology, applied in the field of machinery, can solve the problems of dynamic balance, complex structure, difficult installation and maintenance, etc., achieve the effect of reducing mass, simple and compact structure of the device, and improving the quality of dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

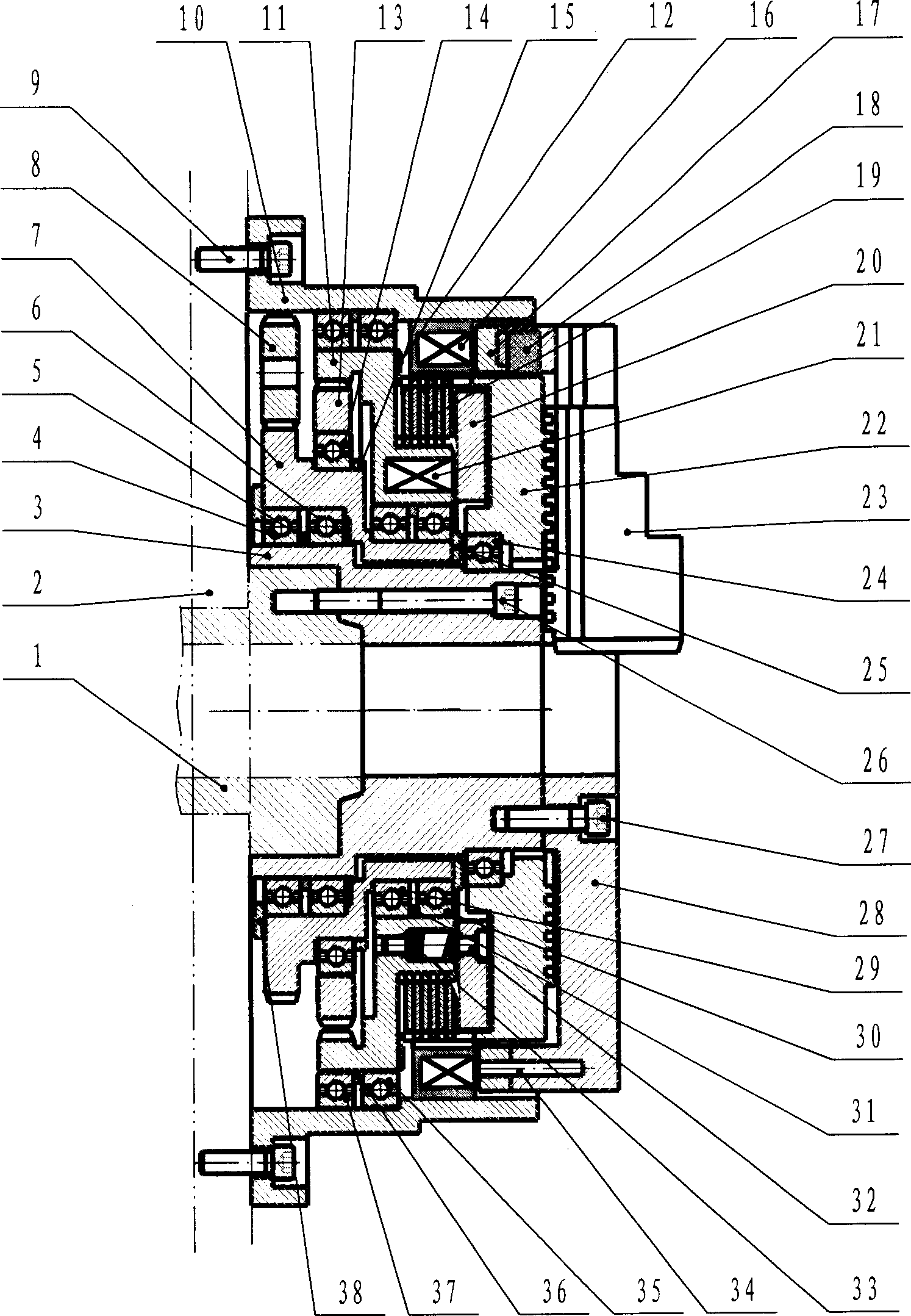

[0025] figure 1 In the structure shown, when the chuck clamps (or loosens) the workpiece, the electromagnetic brakes 16, 17, 34 are energized to act and brake, that is, the electromagnet group 16 is energized to attract the brake ring 17, so that the chuck The body shell 10, the chuck end cover 28, the chuck seat 3, and the main shaft 1 are connected as a whole without rotation; at this time, when the chuck motor (not shown) connected with the gear 8 rotates, the external meshing gear pair 7,8 Move according to the transmission ratio, and the gear 7 is used as an input part and transmits the motion to the internal gear 11 through the gear 13 installed on its eccentric shaft; at the same time, the electromagnetic friction clutch assembly 12, 19, 20, 21 is powered by the slip ring 11 , 32, 33 are energized and act, that is, the electromagnet 21 is energized and the pressure ring 20 is pressed against the friction plate group 19, and the coil wire 22 rotates synchronously with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com