Improved color changing soft tube lamp structure

A hose and white technology, applied in the field of decorative lighting devices, can solve the problems of uneven light color, uncompact and unstable structure, unfavorable color mixing and discoloration, etc., to achieve uniform and continuous light effect, good electrical connection stability, bright and soft The effect of light effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

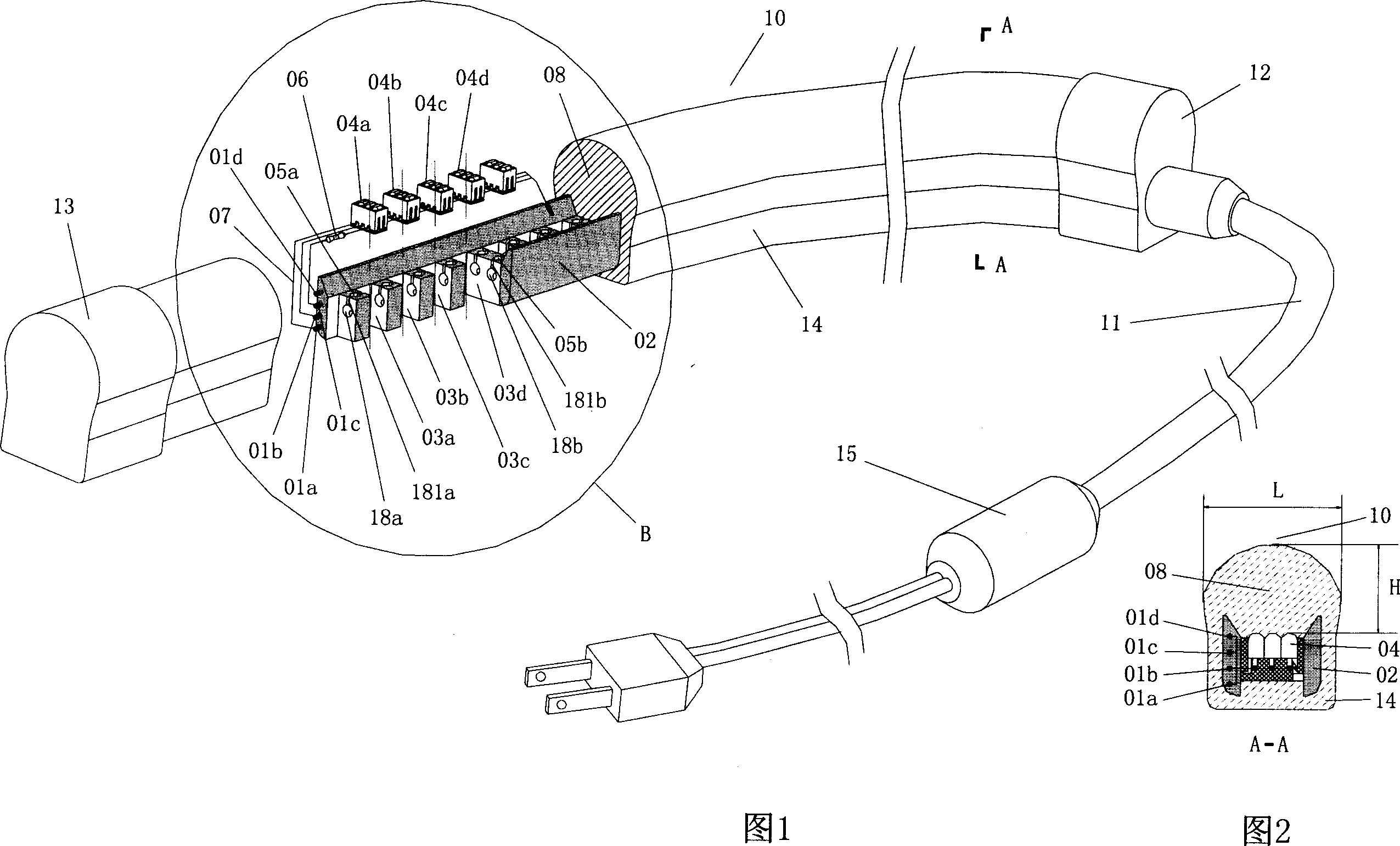

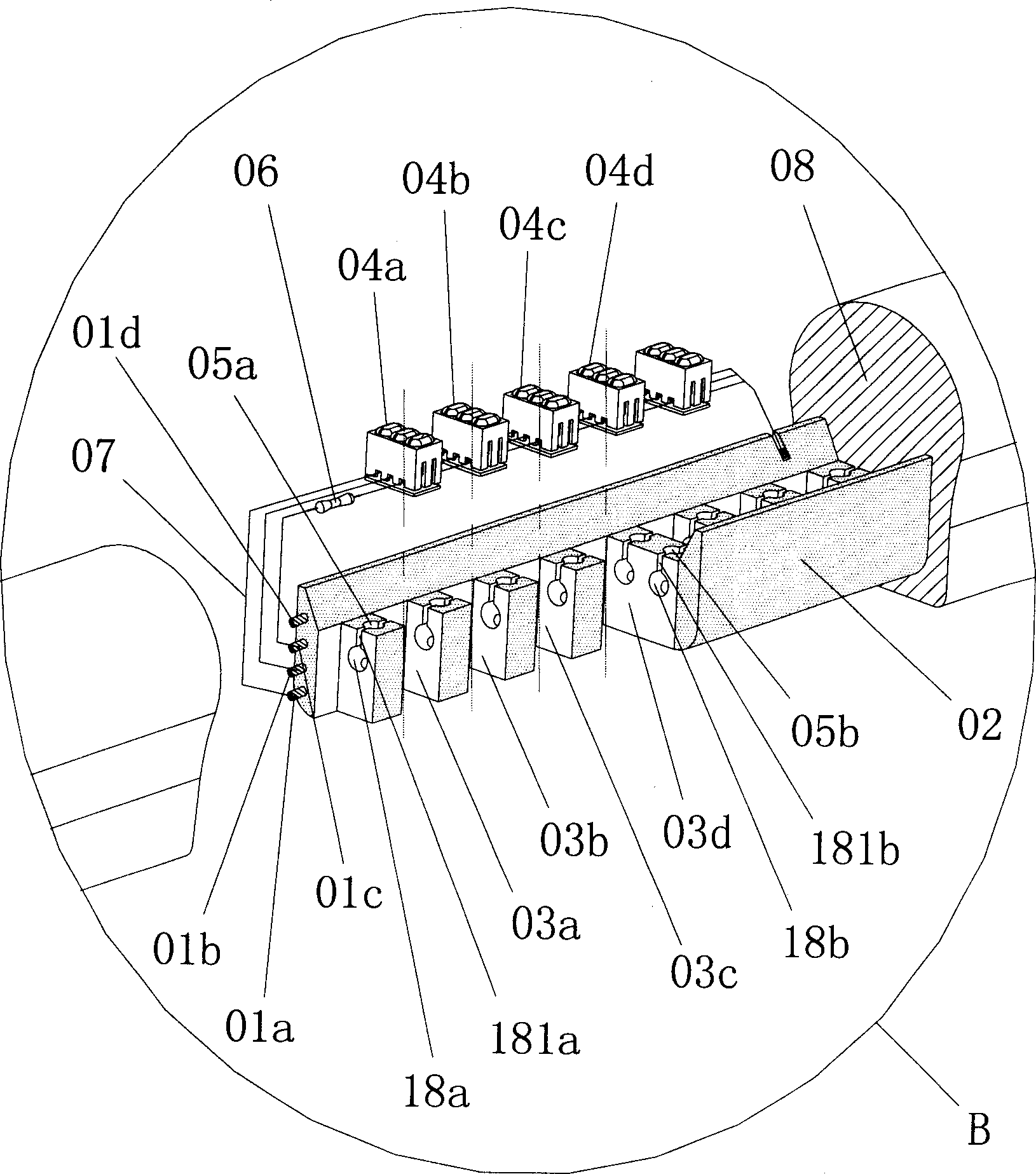

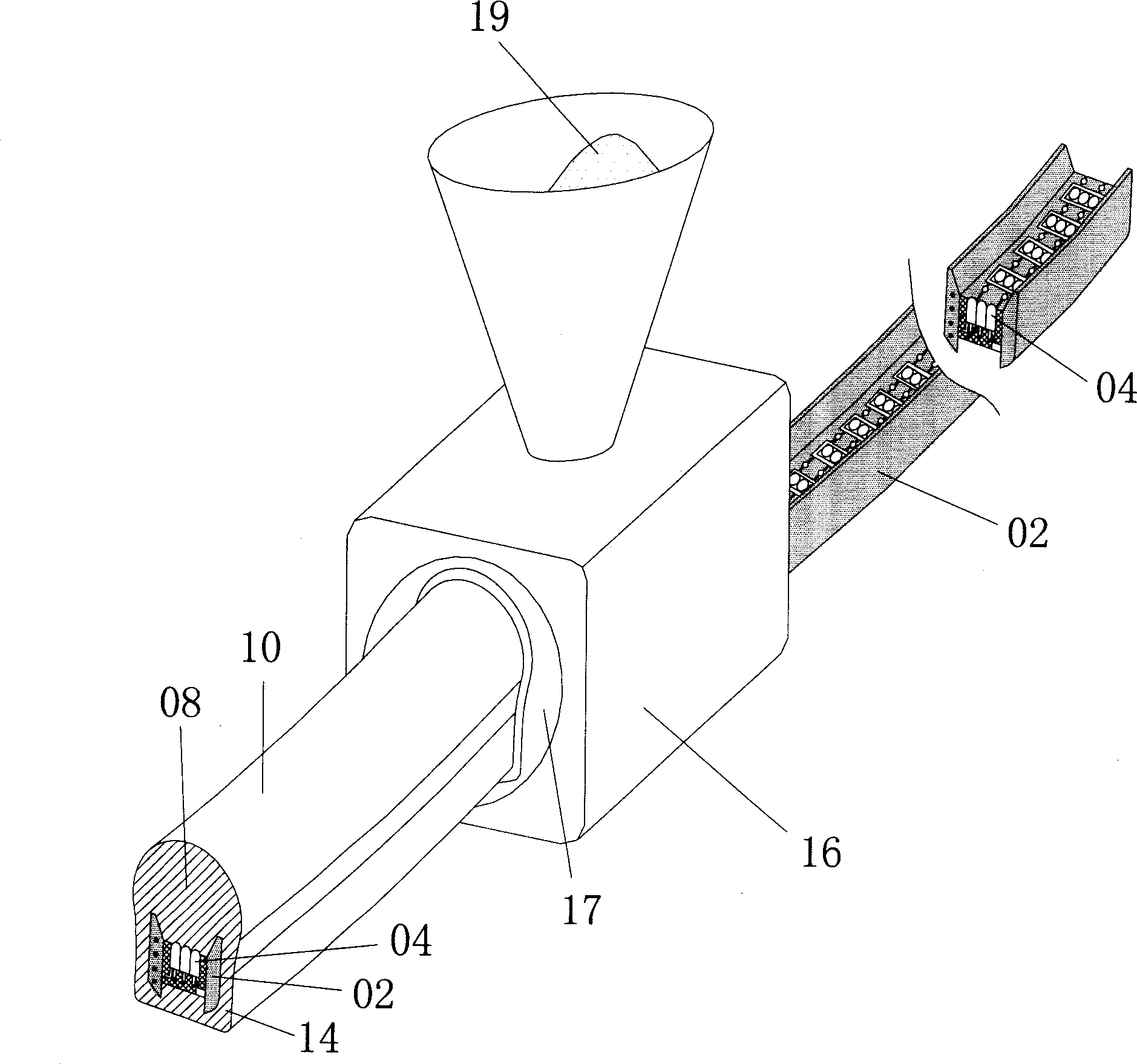

[0022] Below with reference to accompanying drawing, the present invention will be further described:

[0023] Fig. 1 is a perspective view of the present invention, and Fig. 2 is a cross-sectional view of A-A in the perspective view of Fig. 1, image 3 is an enlarged view of B in the perspective view of Figure 1.

[0024] An improved color-changing hose lamp structure of the present invention, its manufacturing process includes: 4 copper stranded wires 01a, 01b, 01c, 01d pass through the forming hole of the extrusion molding machine (not shown in the figure), and the automatic continuous extrusion is carried out by Flexible opaque plastic, usually flexible white opaque PVC material, or a prefabricated length strip formed by other colored plastics, the upper side wall of the strip is provided with a groove, the groove is an inverted trapezoid , the strip is the core wire 02 described in the present invention. In the middle part of the cross section of the core wire 02, two lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com