Compensating method for multiple shaft synchronou position error of magnetic stick flat screen printer

A compensation method and multi-axis synchronization technology, which is applied to the program control and electrical program control of the sequence/logic controller, can solve the problems of increased gaps and inability to ensure error consistency, and achieve improved control accuracy and labor efficiency. Productivity and the effect of eliminating accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

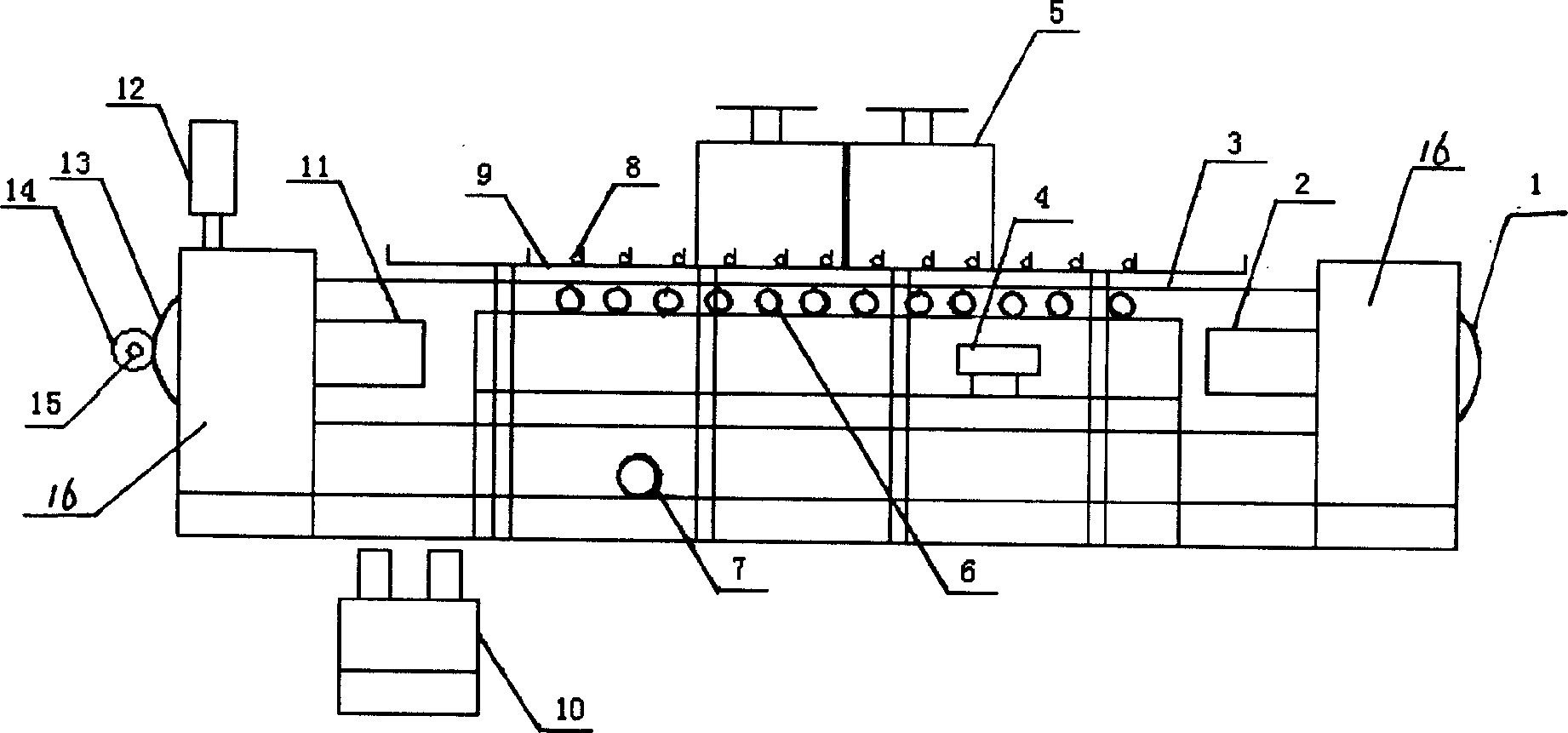

[0015] Such as figure 1 As shown, it is a structural schematic diagram of a magnetic rod flat screen printing machine. The magnetic rod flat screen printing machine is an imported machine equipment, which consists of a driven roller 1, a driven roller servo motor 2, a printing belt 3, and a magnetic rod reciprocating servo motor 4 , electrical control cabinet 5, electromagnetic wire reel 6, washing motor 7, printing magnetic bar 8, printing screen 9, hydraulic station 10, active positioning servo motor 11, operator station 12, driving roller 13, pressure roller 14, encoder 15, fuselage 16 forms.

[0016] The driven roller 1 is connected to the driven roller servo motor 2 and installed on one end of the fuselage 16, the driving roller 13 is connected to the active positioning servo motor 11 and installed on the other end of the fuselage 16, and the printing belt 3 is installed on the driven roller 1 and the driving roller 13 On the top, it moves with the rotation of the drivin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap