Ac drive system for electrically operated vehicle

A drive system and motor technology, applied in the direction of electric vehicles, electric braking systems, drive interaction, etc., can solve the problems that cannot be used to provide the driving force of the wheels, and the danger of sparks in the maintenance of shunt-type motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

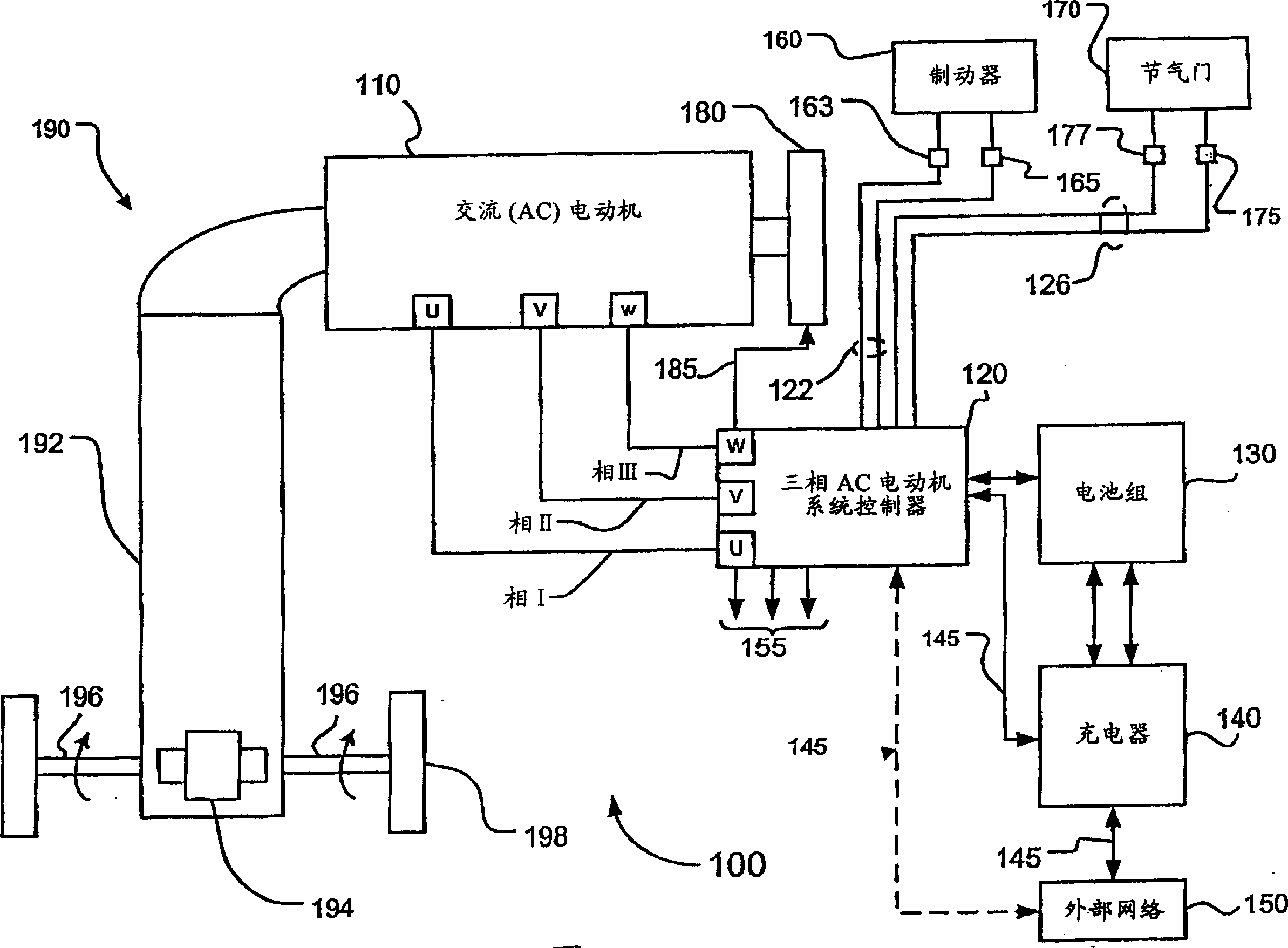

[0052] figure 1 is an exemplary block diagram of an AC drive system in accordance with various embodiments. exist figure 1 An AC drive system 100 is shown in , which may include a three-phase (3φ) AC motor 110 such as an asynchronous motor or a permanent magnet motor, and a matching AC drive motor controller 120 for use in, for example, a golf cart and / or small utility vehicles on electric vehicles 190 . As described below, the AC drive system 100 may provide traction, service braking functions, and may recover and convert kinetic energy of the vehicle 190 into potential energy in the form of electromotive force (EMF).

[0053] refer to figure 1 , in response to motor controller 120 , electric motor 110 may provide motive power to drive wheels 198 , and transfer motive power or traction energy to rear wheels 198 via shaft 192 via locking differential 194 and shaft 196 . Electric motor 110 is operatively connected to electric brake 180 , which is controlled by motor control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com