Pinhole inserted yaw brake of wind electricity generator

A wind turbine and yaw braking technology, which is applied in the control of wind turbines, wind turbines, wind power generation, etc., can solve the problems of brake disc deformation, difficulty in adopting fail-safe, difficult springs, etc., to achieve reliable braking, The effect of simple structure and small operation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

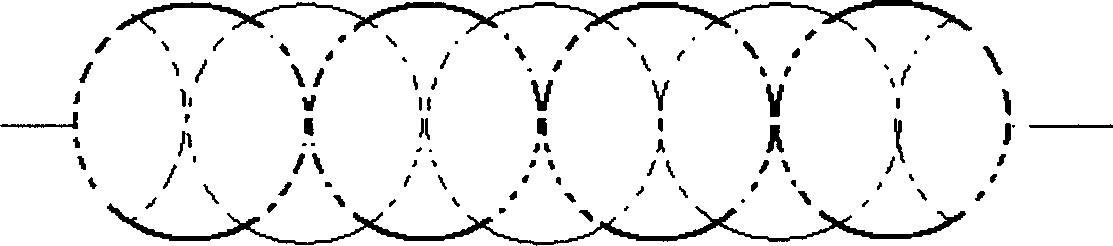

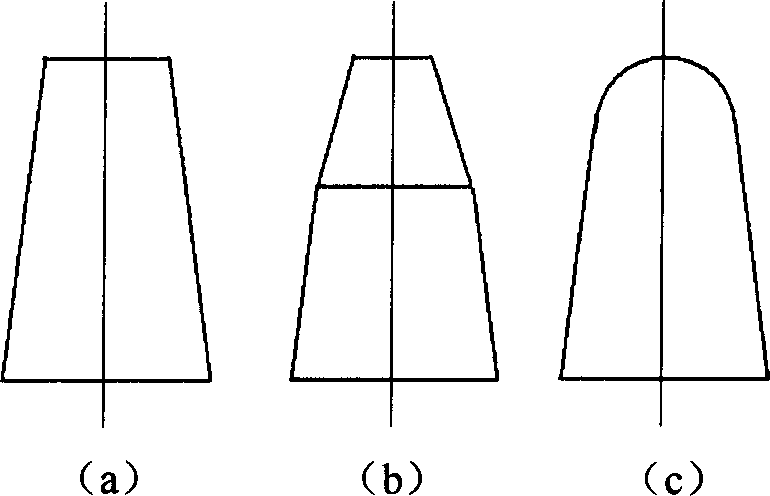

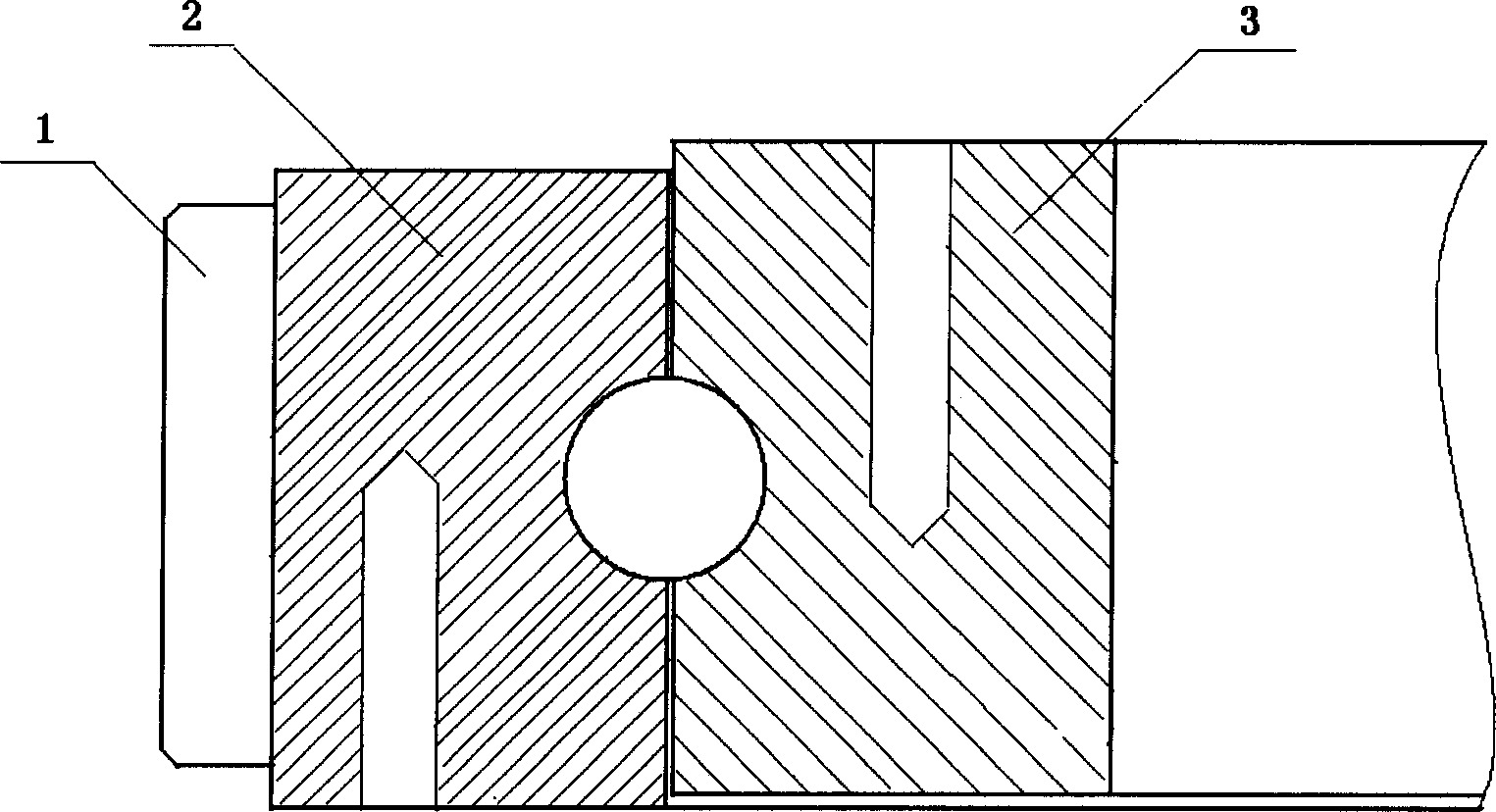

[0021] figure 1 It is a schematic diagram of straight-line development of radial or axial boreholes set on the bearing ring. A series of conical holes are arranged at equal intervals in the axial or radial direction along the same circumference. According to the requirements of yaw accuracy, the hole center distance of these holes can be greater than the diameter of the hole, equal to the diameter of the hole or smaller than the diameter of the hole. figure 2 It is a structural schematic diagram of a conical pin, which can be a single-taper conical pin, a double-taper conical pin, or a conical pin with a spherical upper end. The inner and outer bearing rings of the yaw slewing ring are static and dynamic. The stationary bearing ring is fixed to the tower, and the rotating bearing ring is connected to the base of the nacelle. The conical ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com