Gallium nitride base blue light LED

A blue-light emitting, gallium nitride-based technology, applied in the field of light-emitting tubes, can solve the problems of high operating temperature, low light output efficiency, and affecting the light output rate of GaN blue light-emitting diodes, and achieve the effect of improving light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

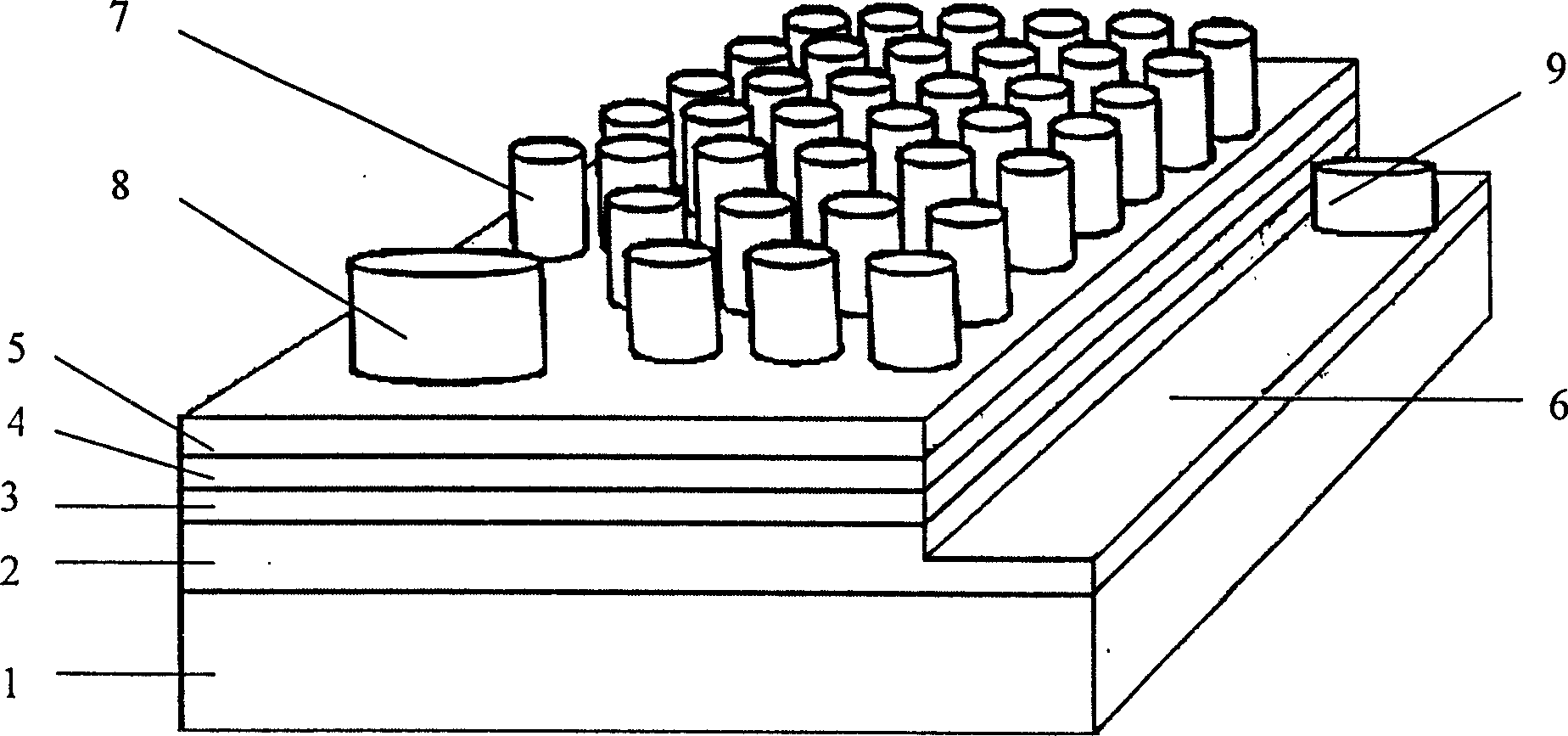

[0013] Such as figure 1 As shown, the present invention is provided with sapphire substrate 1, N-GaN layer 2, active layer 3, P-GaN layer 4 and current spreading layer 5 from bottom to top, on the upper surface of current spreading layer 5 to N-GaN layer The n-type mesa 6 is obtained by etching in step 2. A cylindrical body array 7 is arranged on the upper surface of the current spreading layer 5, and binding posts 8 and 9 are respectively arranged on the upper surface of the current spreading layer 5 and the bottom surface of one end of the n-type mesa 6. The sapphire substrate 1 is used as a substrate for GaN material growth, and its thickness is 400 μm. The thickness of the N-GaN layer is 3 μm, the thickness of the active layer is 0.4 μm, the thickness of the P-GaN layer is 0.5 μm, the thickness of the current spreading layer is 100 nm, the height of the cylinder in the cylinder array is 300 nm, and the cross-sectional diameter of the cylinder is 5 μm. The cylinders in th...

Embodiment 2

[0016] Similar to Embodiment 1, the difference lies in the through n-type mesa 6 obtained by etching from the upper surface of the current spreading layer 5 to the N-GaN layer 2 (see figure 1 ) is changed to partially non-through n-type mesa, or through the groove, and the binding post is arranged on the part of the non-penetrating n-type mesa, or on the bottom plane of the through groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com