Heat compensated oil collection tank

An oil collecting tank and thermal compensation technology, applied in the direction of fractionation, can solve problems such as affecting normal operation, damage to the oil collecting tank, and large deformation due to heat, so as to reduce the residence time, prevent coking, and ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

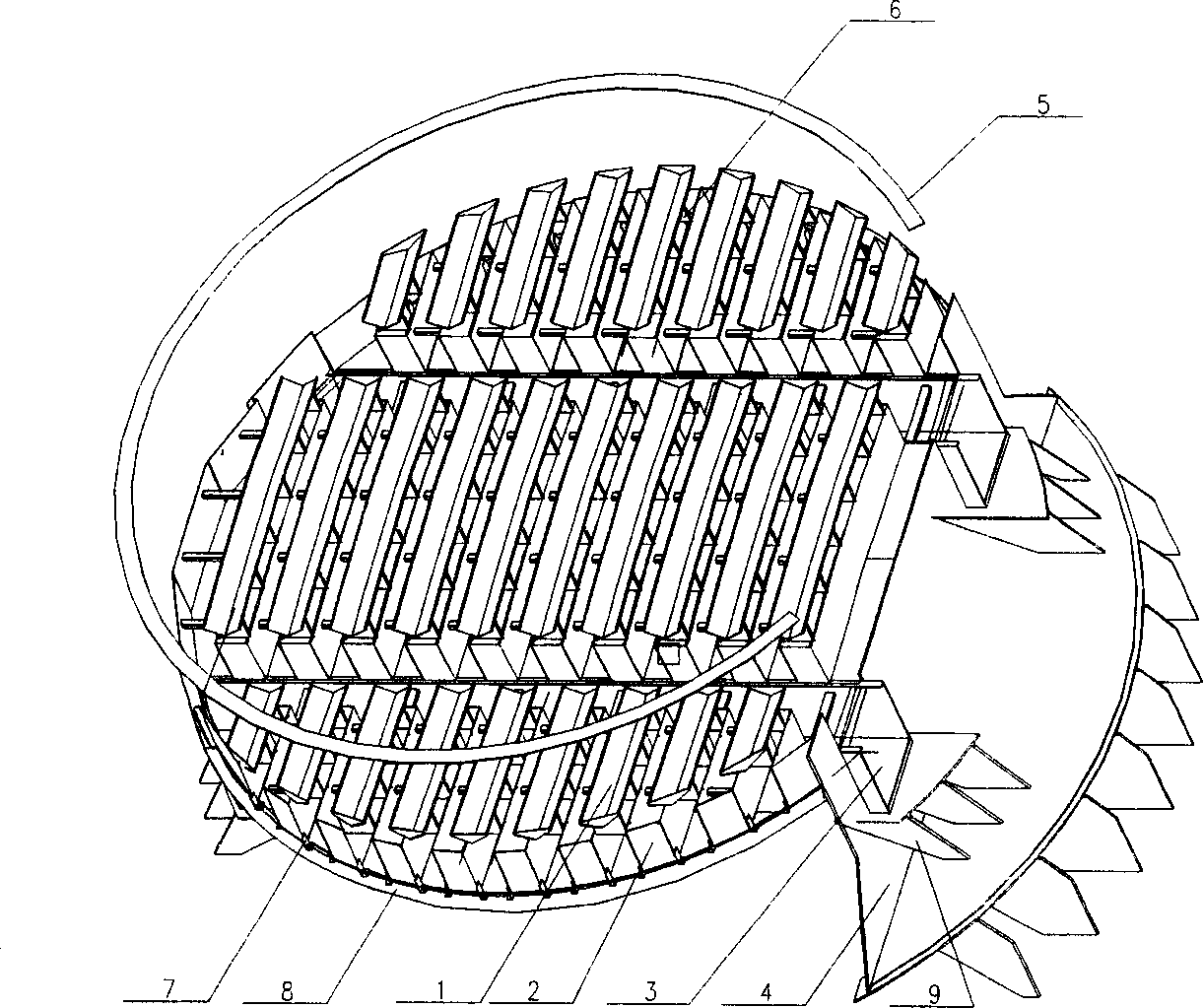

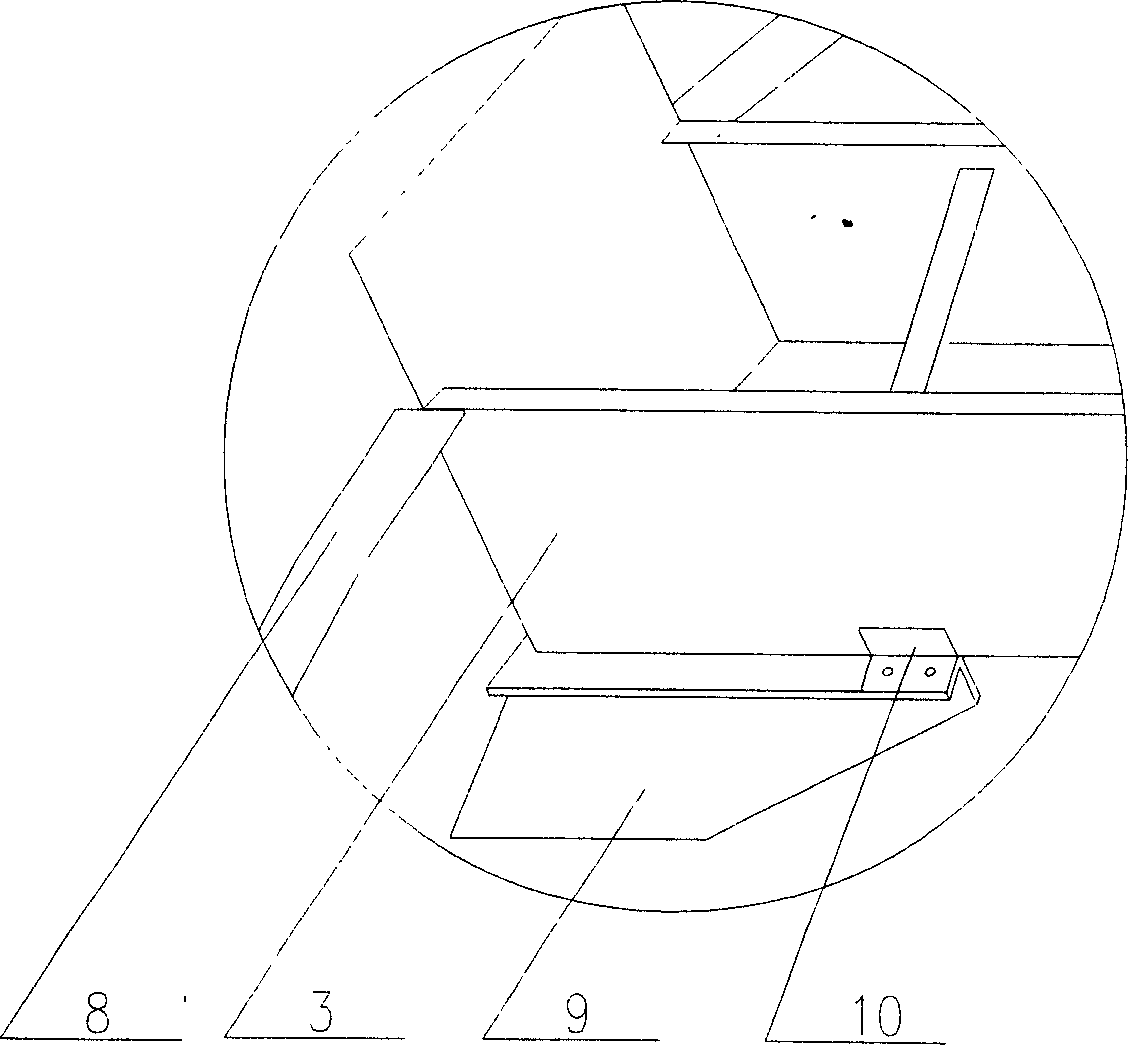

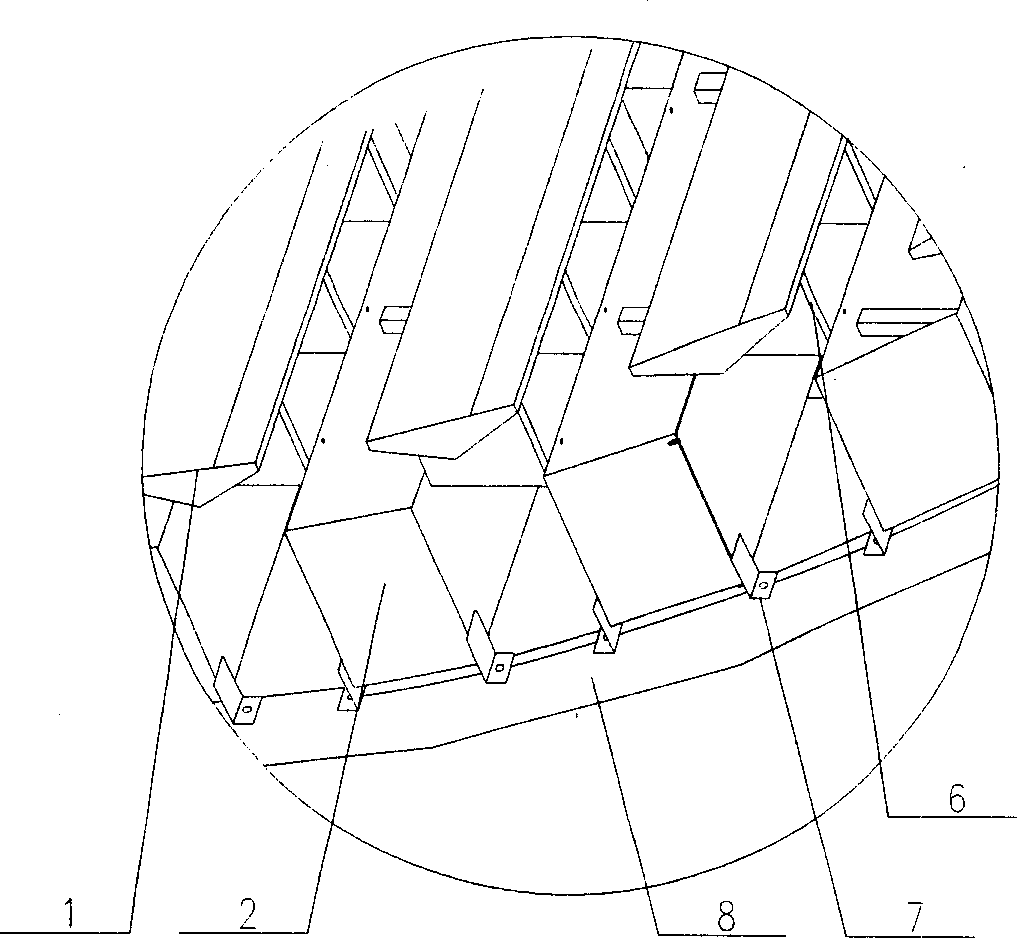

[0026] Such as figure 1 As shown, the heat-compensated oil collection tank includes a liquid collection cap 1, a liquid collection tank 2, a liquid collection channel 3, an extraction bucket 4, a liquid shielding ring 5, a support rib 6, a liquid collection tank limiter 7, a tower ring 8, Components such as the support 9, the liquid collecting channel limiter 10 and the limit expansion ring 11 (wherein the tower ring 8 and the supporting seat 9 are common parts in the tower, and will not be elaborated in the present invention.), the liquid collecting channel 3 The fixed end of the sump is fixed on the extraction bucket 4 or the support 9, the free end is lapped on the support 9 and the lateral position is limited by two sump stoppers 10, and the fixed end of the sump 2 is fixed on the sump 3, the free end is lapped on the tower ring 8 and its lateral position is limited by two liquid sump stoppers 7, the liquid collecting cap 1 is fixed between the liquid sump 2 through the su...

Embodiment 2

[0032] The difference from Example 1 is that when there are two or more sumps 3, the fixed end of the sump 2 between the sump 3 and the support 9 is fixed on the side plate of the sump 3, and the free end It is sealed by a blocking plate and rests on the tower ring 8, and the lateral position is limited by the liquid sump limiter 7, and its thermal deformation can be compensated by the free expansion and contraction in the longitudinal direction. Both ends of the sump 2 located between the two sump channels 3 are fixed on the side plates of the sump channels 3 , and its thermal deformation can be compensated by the deformation of the side plates of the sump channels 3 .

Embodiment 3

[0034] The difference from Example 1 is that when there are two or more collecting channels 3, both ends of the collecting cap 1 located between the two collecting channels 3 are open, so that the liquid flows to the collecting channels on both sides respectively. within 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com