Non-contact pulp flow pulse reducer for high-speed paper machine approach flow system

A non-contact, high-speed paper machine technology, applied in the direction of paper machine, paper machine wet end, pipeline system, etc., can solve the problems of little influence, complex structure, and reduced inhibition, and achieve easy replacement, simple device structure, Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

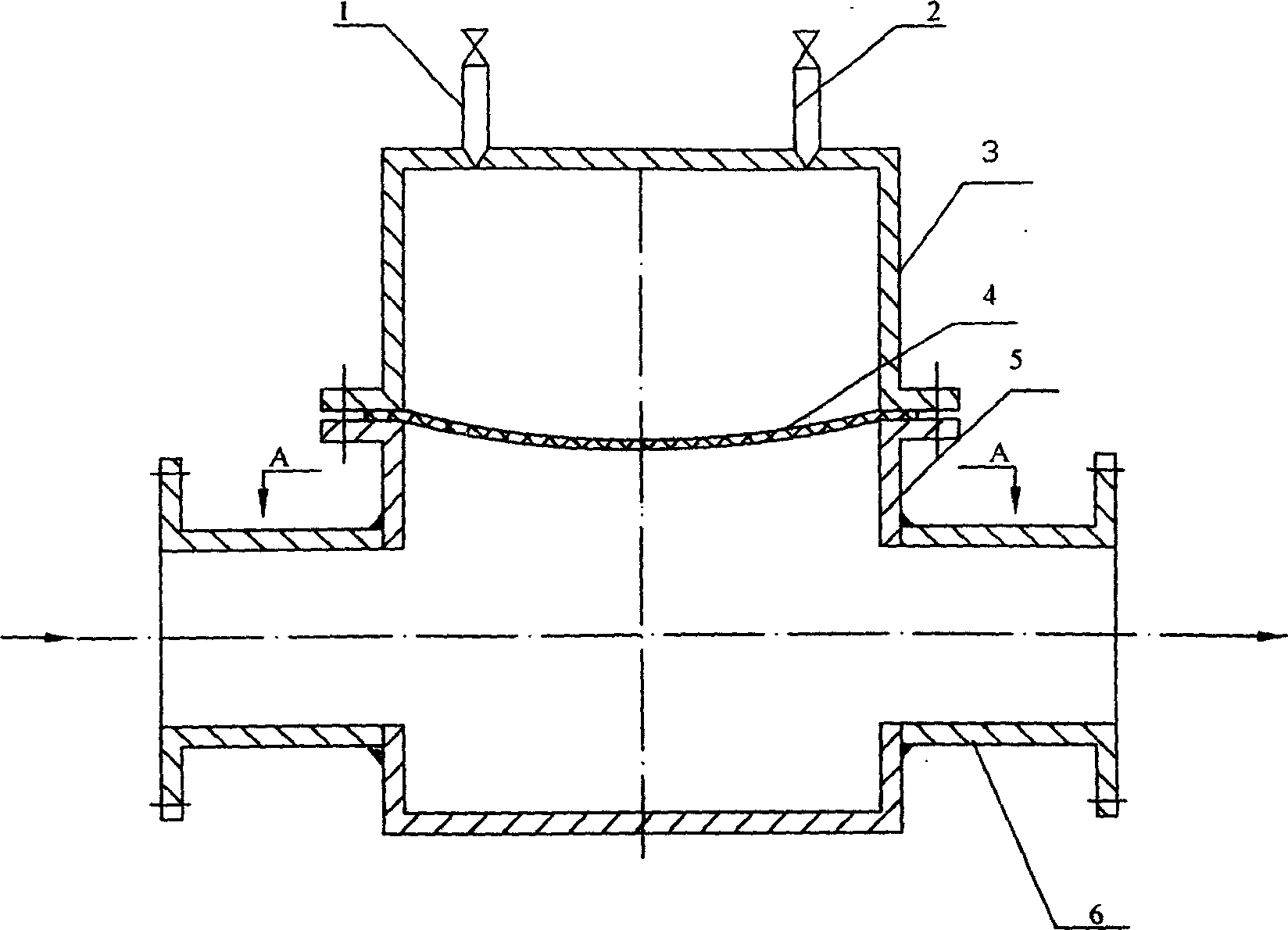

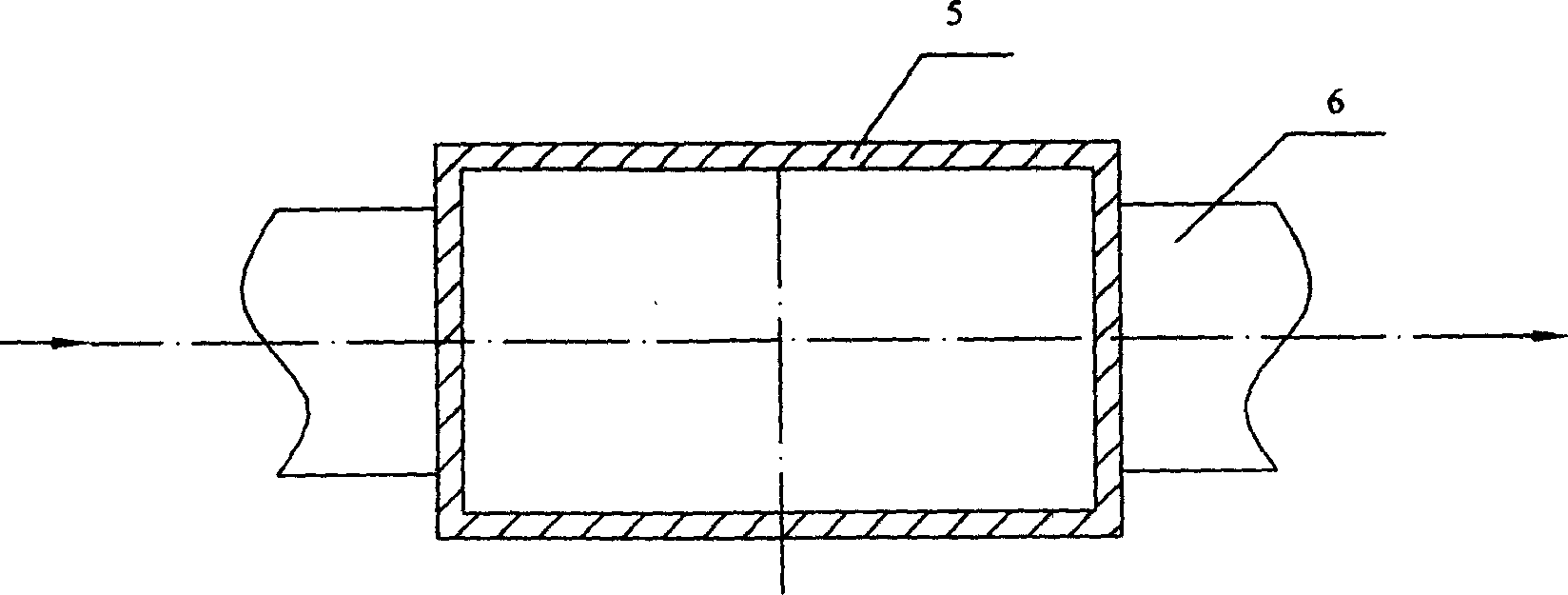

[0020] like figure 1 As shown, a non-contact pulp flow pulse reducer for the high-speed paper machine flow delivery system includes an air chamber 3, an elastic rubber diaphragm 4, and a suddenly expanded rectangular pulp stabilization pipe 5. The two-stage pulp flow pipe The cross-sectional area of the suddenly expanding rectangular slurry-stabilizing pipe 5 connected to the road 6 is greater than the cross-sectional area of the slurry flow pipeline 6, and the suddenly expanding rectangular slurry-stabilizing pipe 5 lower ends are closed, and the upper end is connected to the air chamber 3, and the suddenly expanding rectangular slurry-stabilizing pipe 5 is connected to the An elastic rubber diaphragm 4 is arranged between the air chambers 3 , and the air chambers 3 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com