Motor-operated valve

An electric valve and motor technology, applied in the direction of lift valve, valve device, valve details, etc., can solve the problems of increasing processing cost, control roughness, contact, etc., and achieve the effect of high-precision control and improvement of decomposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

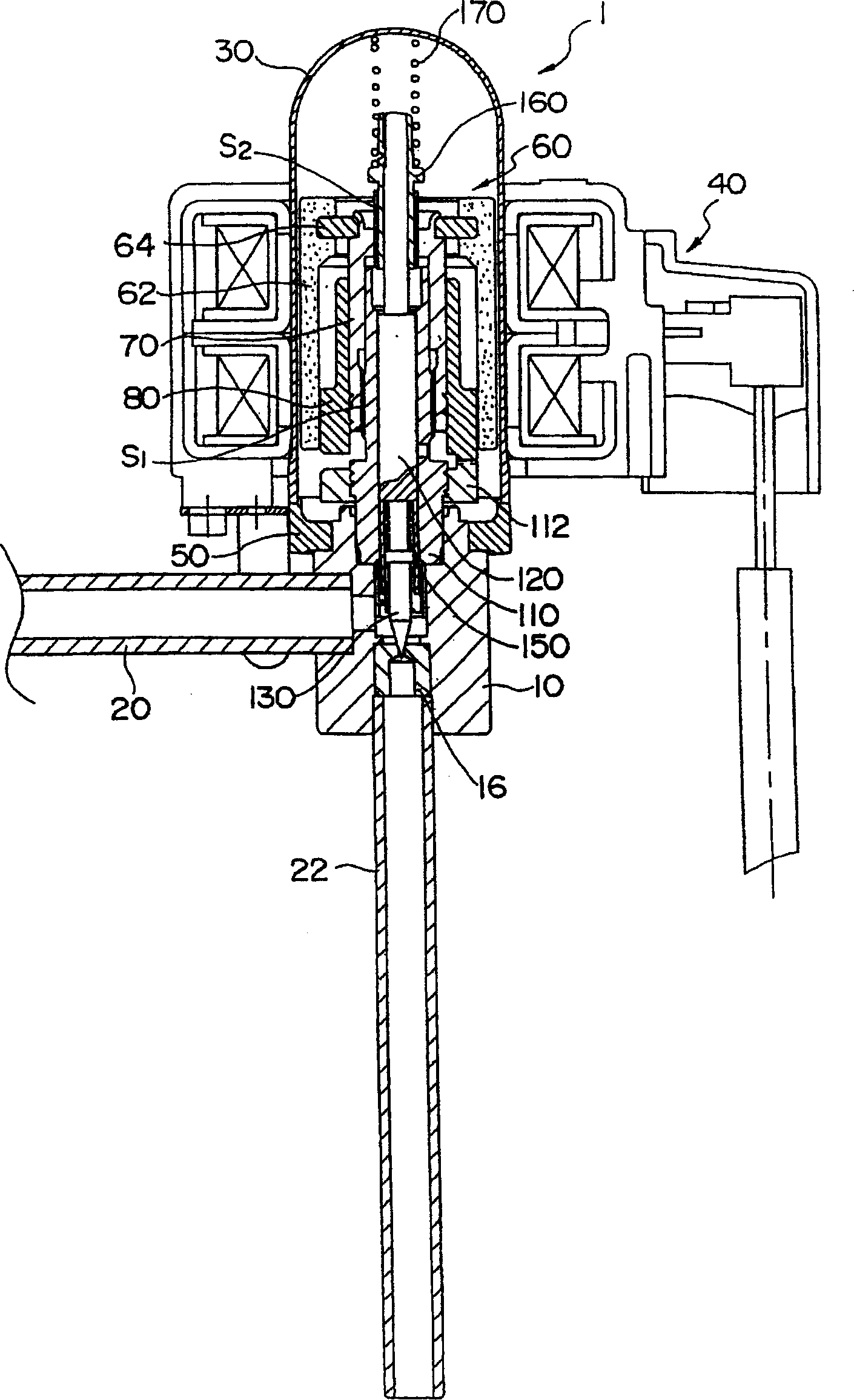

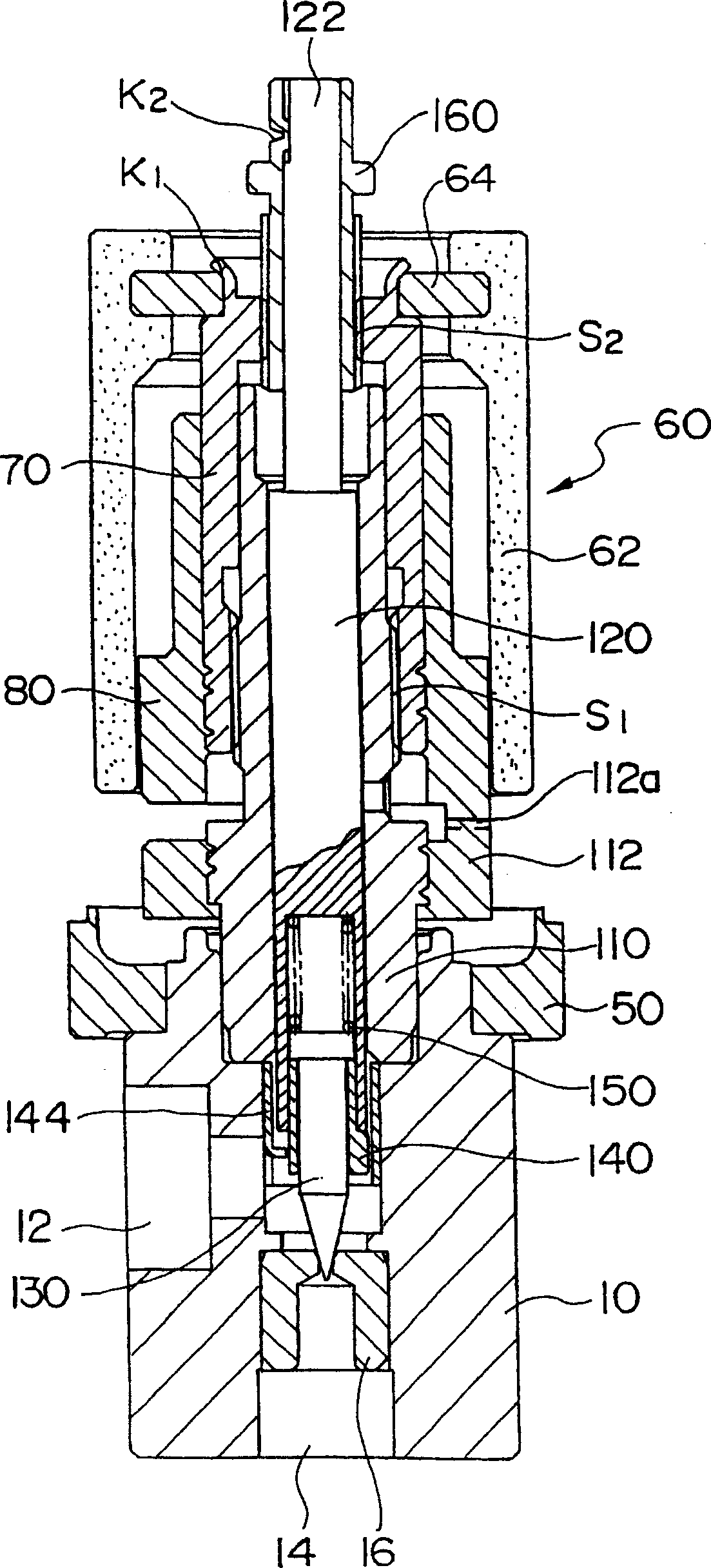

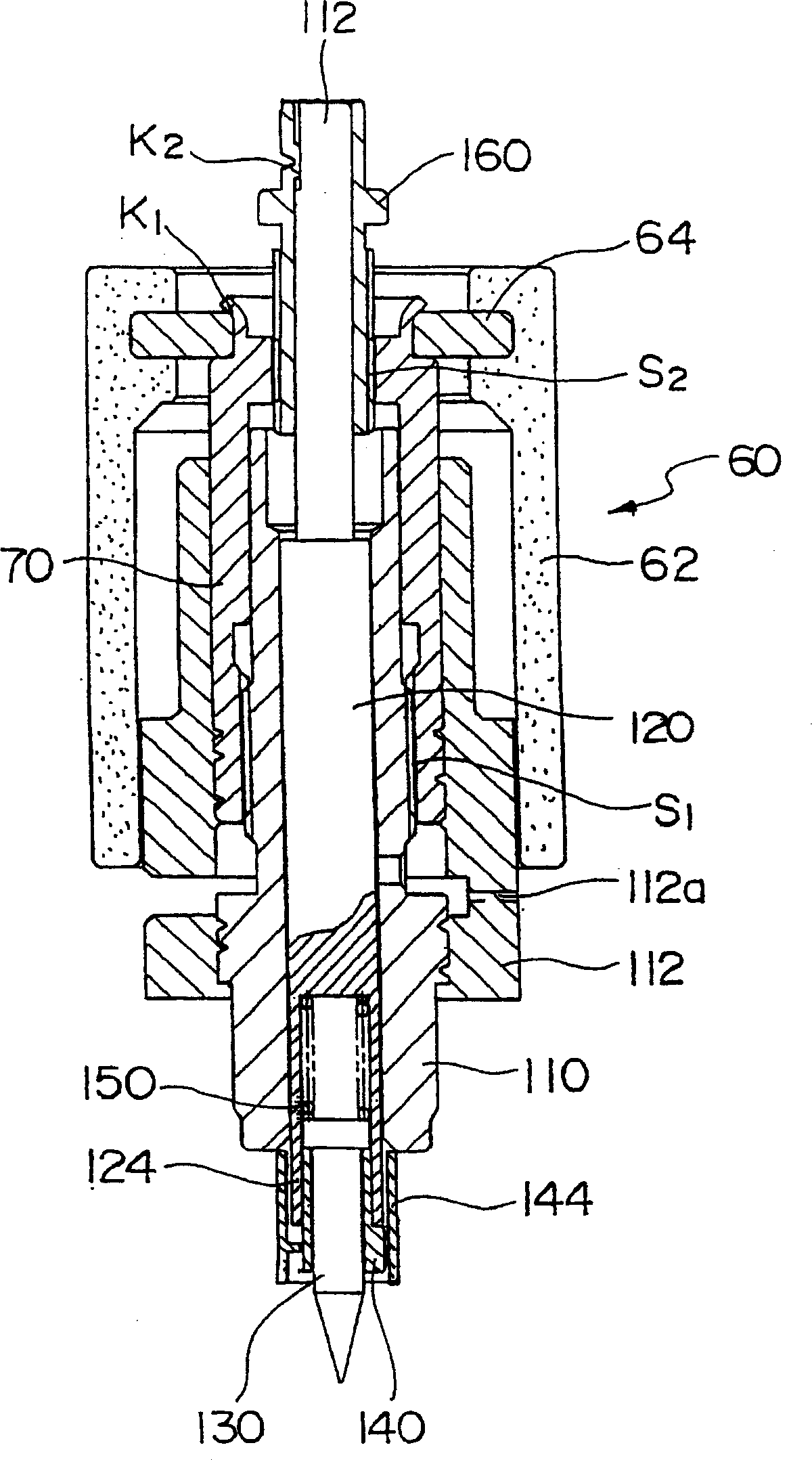

[0021] figure 1 The whole structure of the electric valve of this invention is shown.

[0022] An electric valve denoted as a whole by reference numeral 1 has a valve body 10 , and a valve seat member 16 is inserted into the valve body 10 . Pipes 20 and 22 are connected to the valve body 10 .

[0023] The shell 30 which is a cylindrical pressure vessel is fixed to the upper part of the valve main body 10 via the receiving member 50 . A stator unit 40 of a stepping motor, which is an example of a driving motor, is disposed outside the case 30 .

[0024] The rotor unit 60 is rotatably arranged inside the housing 30 . The rotor unit 60 includes a rotor 62 composed of a plastic magnet formed by mixing a magnetic material with resin, and a screw feeding member 70 connected to the rotor 62 through a ring member 64 .

[0025] The screw feeding member 70 has a first threaded portion S1 and a second threaded portion S2 formed in the same direction of rotation, and the pitch of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com