Method of lightning proofing a blade for a wind-energy plant

A technology for wind energy equipment and lightning protection, which is applied in the field of wind energy equipment and lightning protection blades, can solve problems such as damage, achieve good electrical connection, and avoid the effect of blade processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

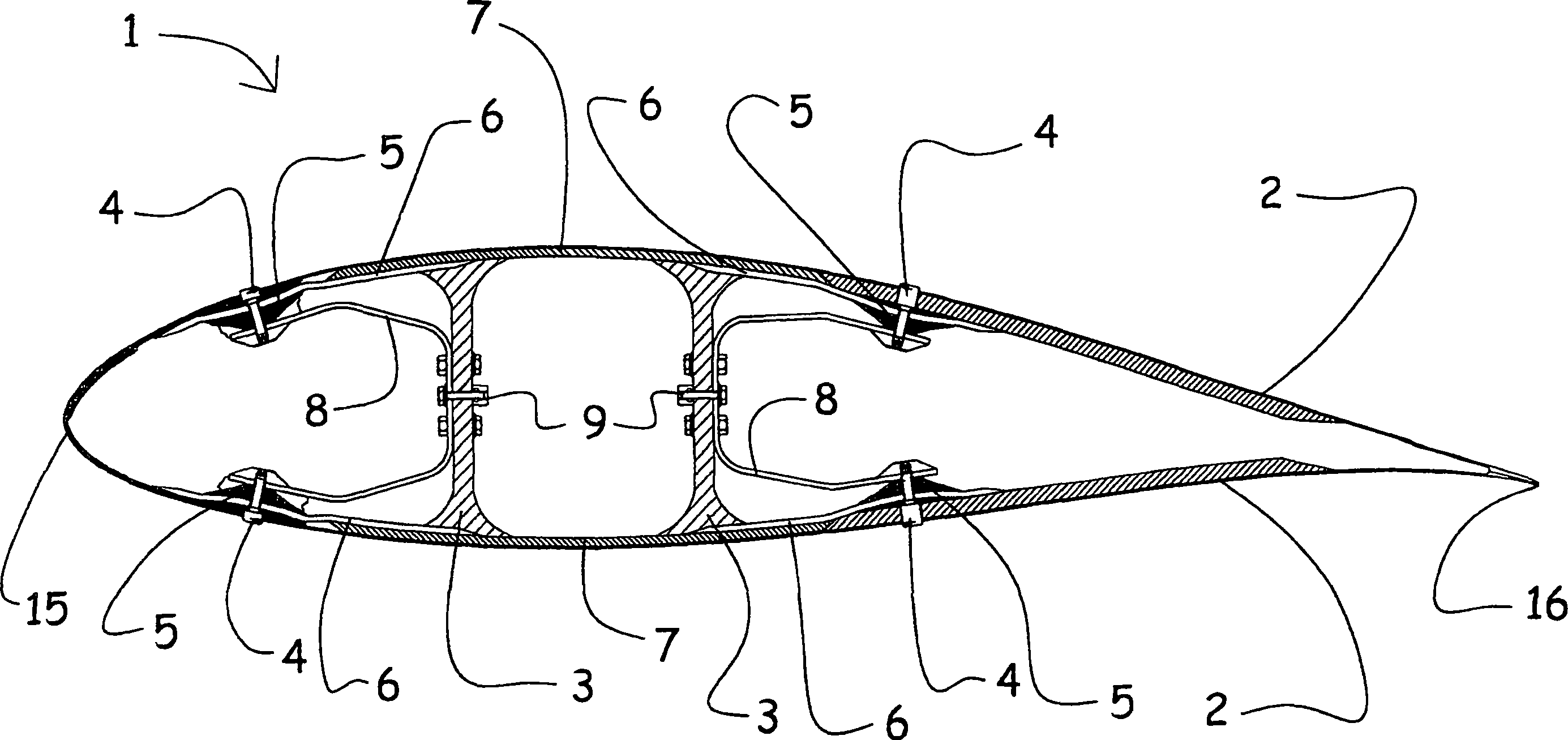

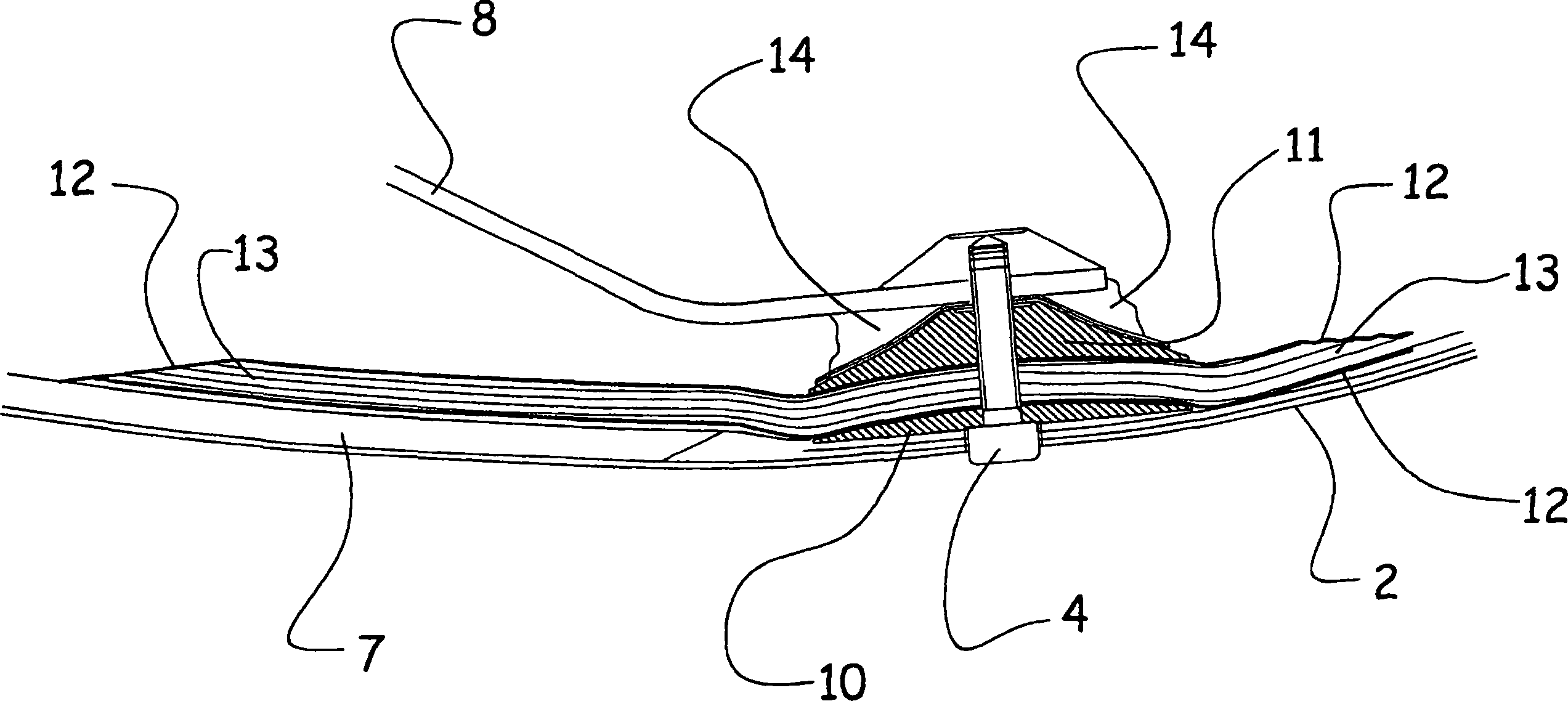

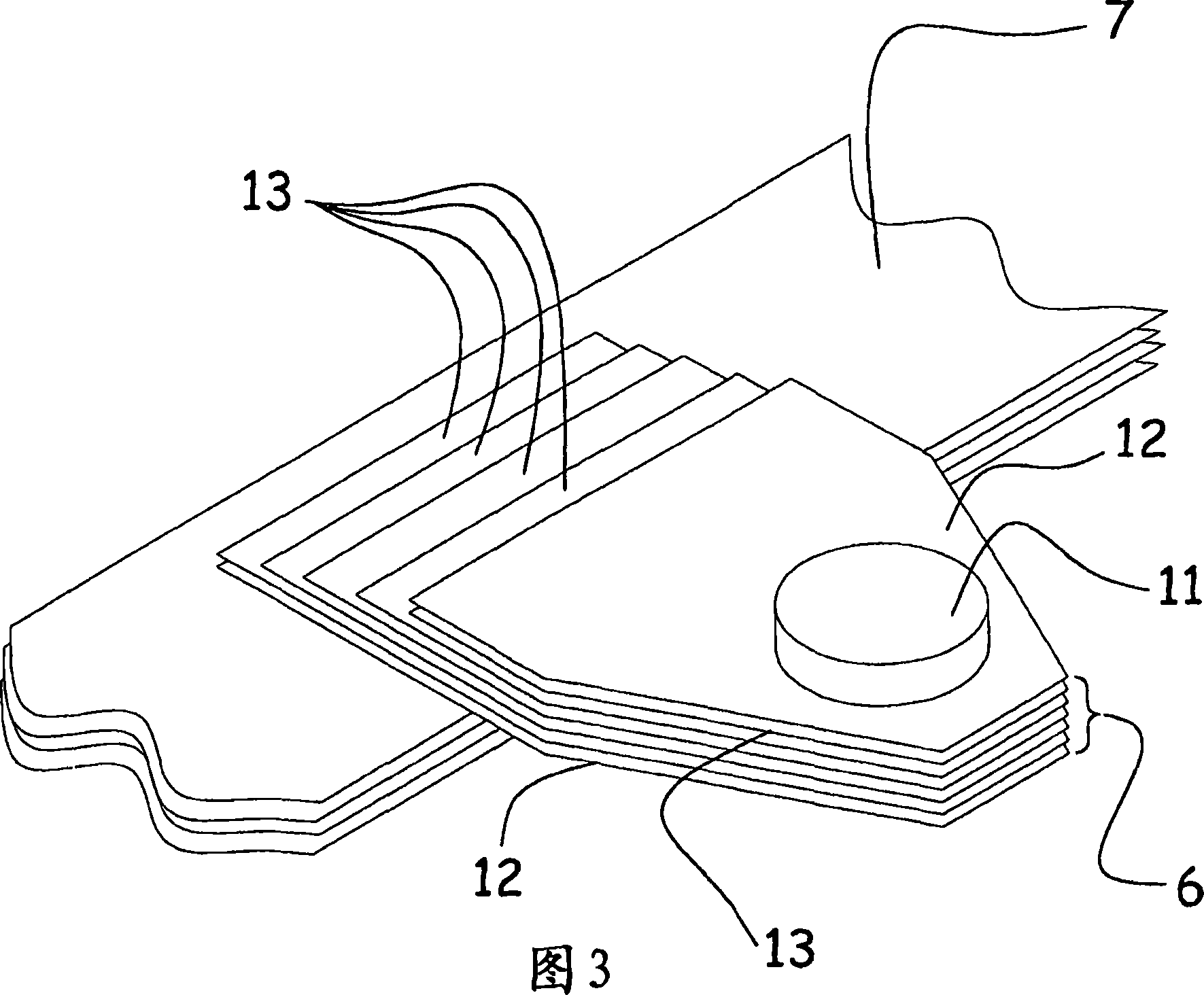

[0036] figure 1The illustration shows a blade 1 for a wind energy installation. The blade 1 comprises a blade shell 2 which forms the aerodynamically active part of the blade. The blade shell 2 comprises an upper main laminate 7 by which an essential part of the strength and rigidity of the blade is achieved. For supporting purposes, two substantially longitudinally extending beams 3 are arranged inside the blade. The leading and trailing edges of the blades are denoted by reference numerals 15 and 16 respectively. As part of the lightning protection method of the blade 1 shown, a metal receiver 4 is provided at the outer surface of the blade shell 2 . The term "receiver" is to be understood as an electrically conductive object configured for the purpose of capturing and conducting lightning currents. The receiver 4 is connected to a lightning arrester 9 via a connection 8 . The receiver 4, the connection 8 and the arrester 9 are metallic objects configured to be able to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com