Method for the catastrophic transfer of a thin layer after co-implantation

A transfer method and thin-layer technology, applied in electrical components, microstructure technology, semiconductor/solid-state device manufacturing, etc., can solve problems such as no derivation, and achieve the effect of avoiding ring defects, improving topology, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

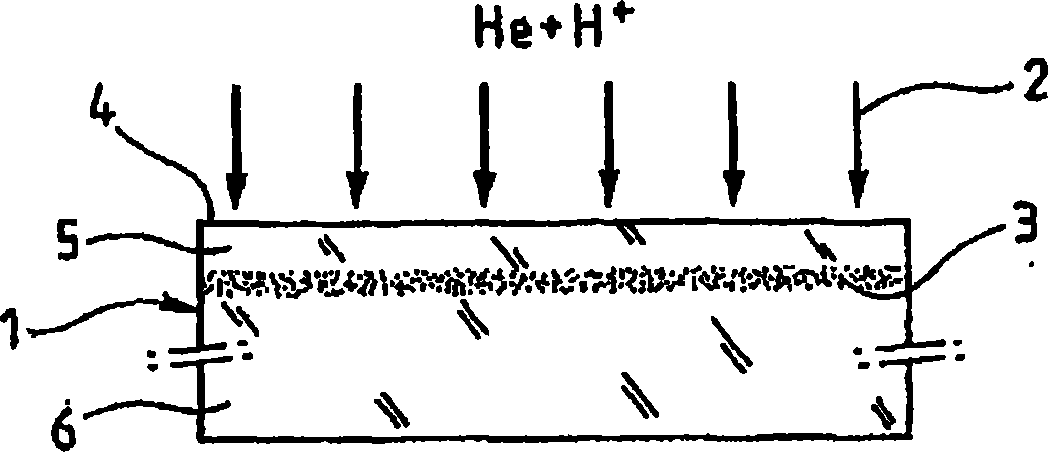

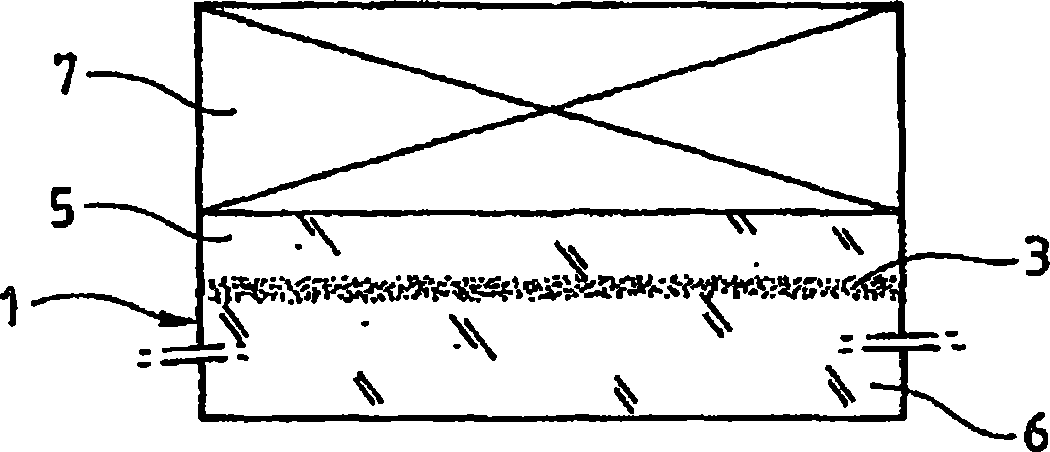

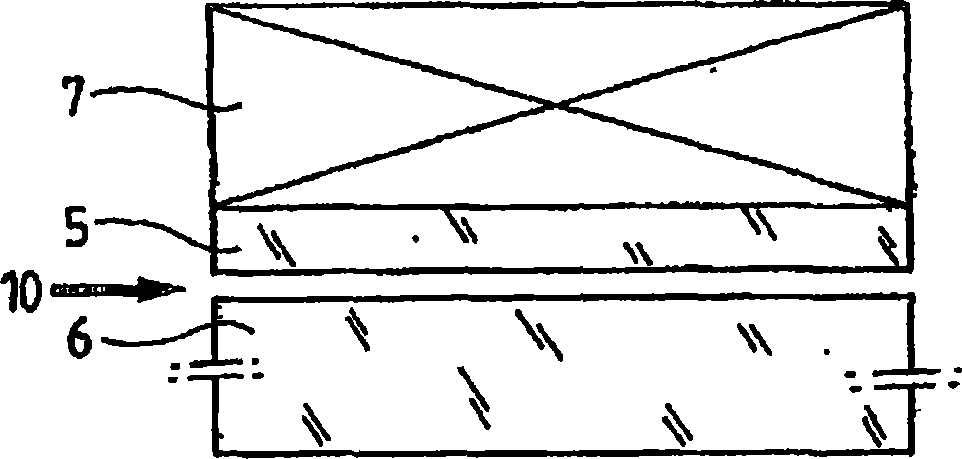

[0100] Joint injection

[0101] According to a first embodiment of the present invention, one contains a thermal SiO on the surface (for example, 145nm) 2 The layer of Si substrate (-700μm) can be at 70KeV-10 16 He / cm 2 Helium atoms were injected under the injection conditions of 30KeV-4.25×10 16 H / cm 2 Hydrogen atoms are injected under the same injection conditions. This achieves that the deepest contour line is injected first. The source substrate can then be bonded to a target Si substrate (-700 μm) by molecular bonding. Then, this structure is subjected to heat treatment at about 350°C for a certain period of time (for example, 2 hours). If the heat treatment is adjusted, as disclosed in, for example, European Patent Application 02-293049, the window for obtaining the self-sustained fracture phenomenon is about several hours (ie, the brittle annealing between 2 and 6 hours). Then, as soon as a blade is inserted between the bonding interfaces in the form of impact, the self-sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com