Non PVC film welding mould

A technology for welding molds and mold bodies, which is applied to paper/cardboard containers, container manufacturing machinery, and box production operations, etc. It can solve the problems affecting the appearance of the bag shape and the surrounding welding strength, inaccurate temperature control of the mold working surface, and the time required for the mold. Long and other problems, to achieve the effect of fast and convenient replacement and adjustment, direct and accurate temperature detection feedback, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

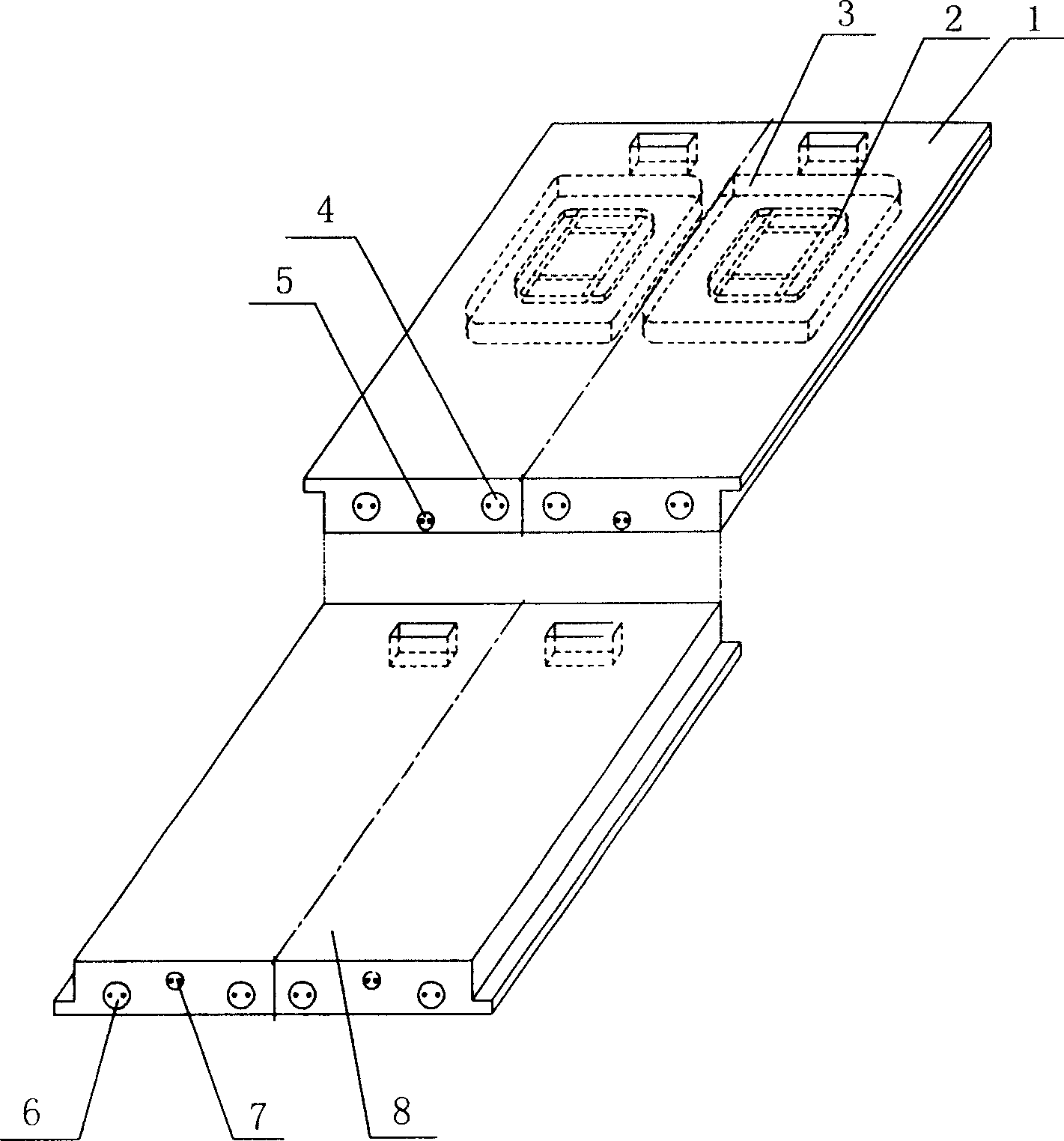

[0011] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

[0012] As shown in the figure, the non-PVC film welding mold of the present invention includes a corresponding upper mold body 1 and a lower mold body 8, the upper mold body is provided with a cooling plate 2, and the lower mold body 8 is provided with a cooling liquid circulation inner Cavity, that is, the lower mold body 8 and the cooling plate are made into an integrated structure, and electric heating rod jacks and thermocouple jacks are set on the upper mold body 1 and the lower mold body 8, and the electric heating rods 4 of the upper and lower mold bodies 1 and 8 , 6 and thermocouples 5, 7 are respectively inserted in their corresponding jacks.

[0013] The cooling plate 2 on the upper mold body 1 cools the non-PVC film to prevent the non-welding surface from melting due to excessive temperature during welding, and only processes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com