Drum photocatalysis reactor

A photocatalytic reactor and rotating drum technology, applied in the direction of light water/sewage treatment, etc., can solve problems such as affecting the processing capacity of the reactor, and achieve the effects of small footprint, low treatment cost and low energy consumption

Inactive Publication Date: 2006-11-29

TIANJIN UNIVERSITY OF TECHNOLOGY

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The common feature of the existing reactors is that the main part of the reactor is static, and the distribution of the treatment liquid and the catalyst is adjusted depending on the fluid flow rate and the amount of catalyst added or loaded. This adjustment method will affect The throughput of the reactor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0021] Add 5L of 4BS direct dye with an initial concentration of 5mg / L to the first drum type photocatalytic reactor, and after 7 hours of reaction, the decolorization rate of 4BS dye reaches 63.98%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

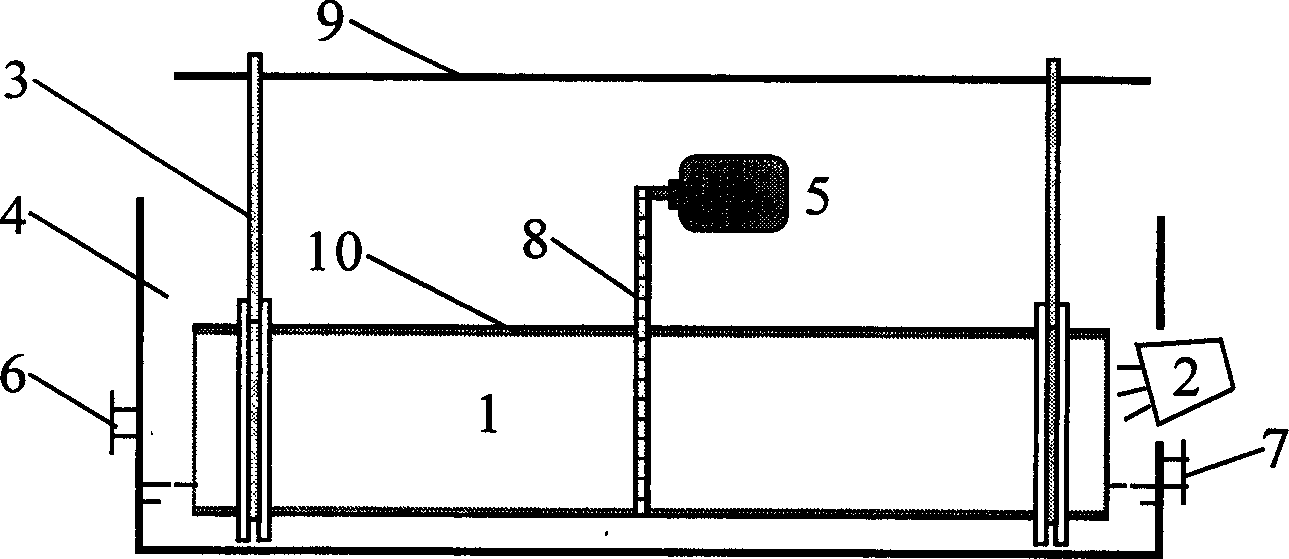

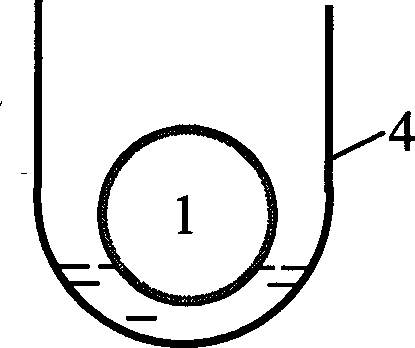

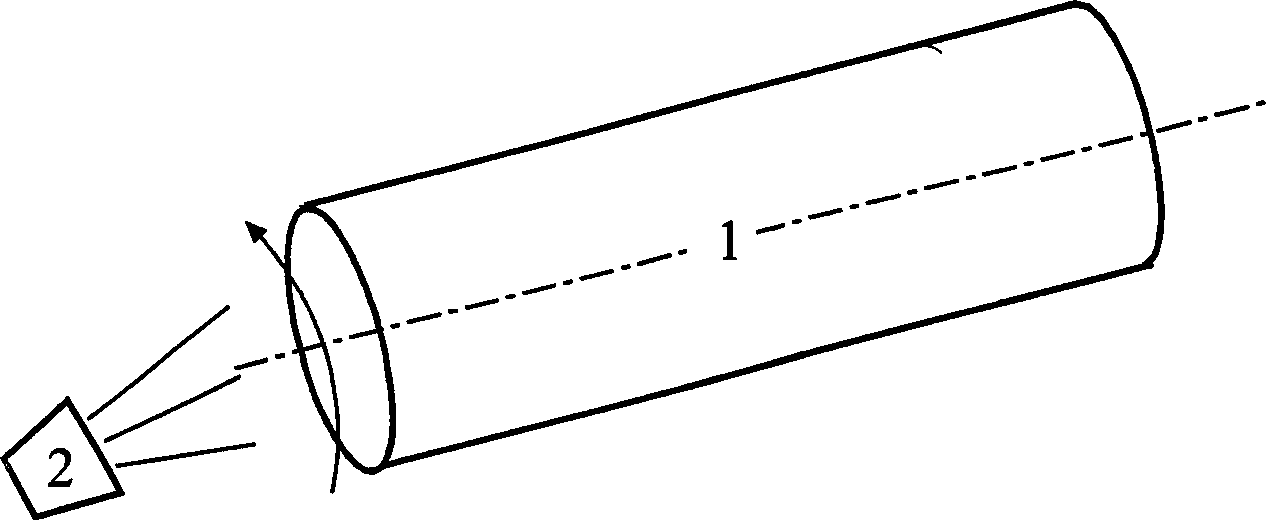

A rotary drum type photo-catalytic reactor for treating sewage is composed of a water bath with water inlet and outlet, a rotary drum arranged horizontally in said water bath by a supporting frame and with coated TiO2 photo-catalyst layer on its inner surface, a speed adjustable motor for driving said rotary drum via gear set, and an ultraviolet lamp able to irradiate the inner surface of rotary drum by a certain angle.

Description

technical field [0001] The invention relates to a photocatalytic water treatment reaction device. Background technique [0002] Photocatalytic water treatment technology is moving from laboratory to practical application due to its wide applicability and high efficiency. At this time, reactor design has become an important link in whether this technology can be industrialized. The photocatalytic water treatment reactor integrates the light source, catalyst and treatment liquid, and can make it a place to maximize the photocatalytic reaction to treat sewage. Therefore, it should have the ability to fully contact the catalyst, treatment liquid, and photons. basic features. High treatment intensity, low treatment cost and wide adaptability are the basic requirements for photocatalytic water treatment reactors. [0003] At present, there are two main types of photocatalytic water treatment reactors: one is a fixed-bed reactor (including a membrane reactor) that loads a cataly...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/32

Inventor 尹晓红辛峰张凤宝王世铭张国亮

Owner TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com