Method and equipment for building gas phase circulation driven by inert gas in hydrocarbon class of liquid phase in narrow distillation

A technology of gas phase circulation and inert gas, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reduced normal operation efficiency, large pressure fluctuations, unstable flow, etc., and achieve the effect of overcoming the design load method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

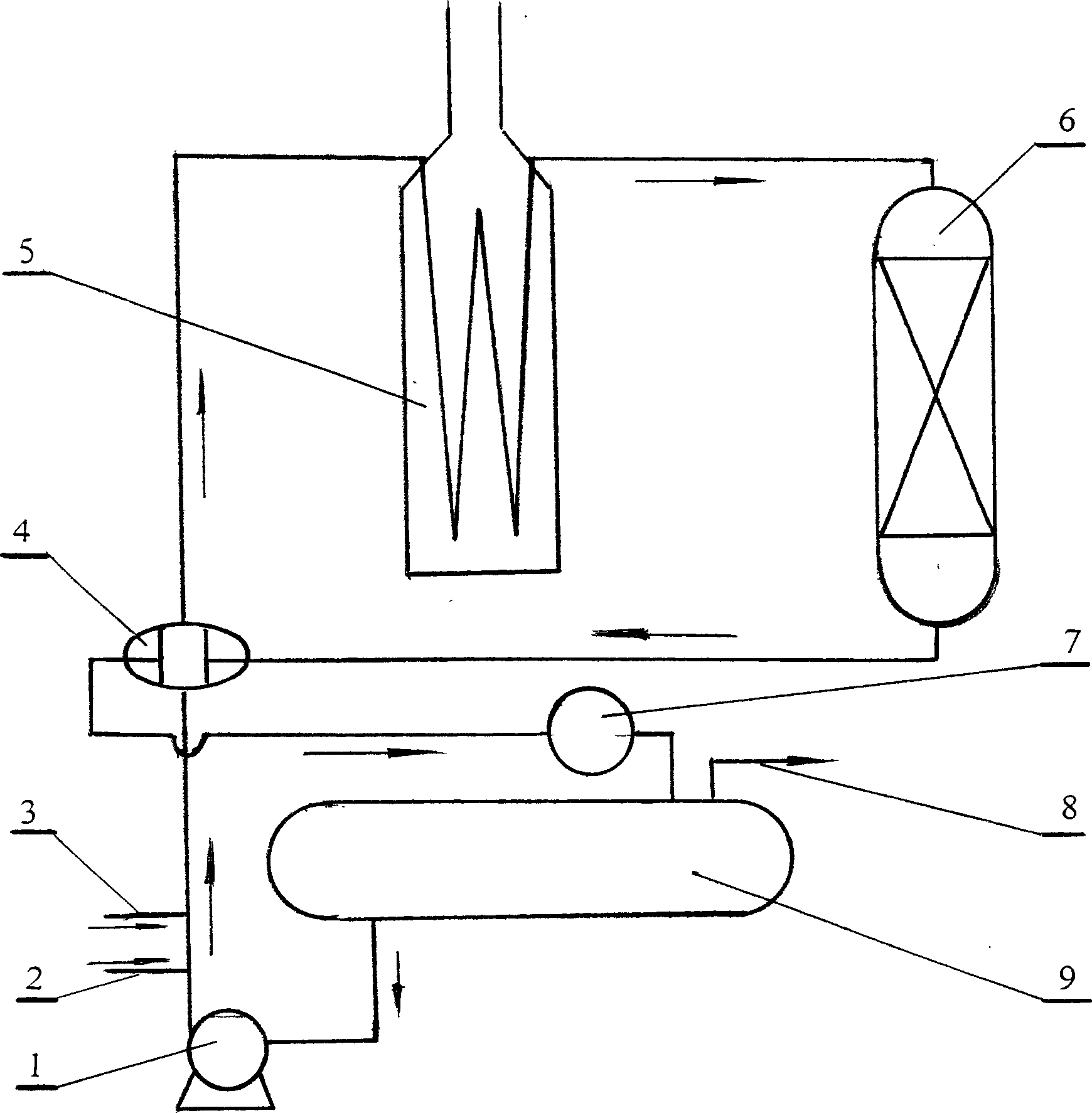

[0018] As shown in the drawings of the description, the device for promoting the establishment of gas-phase circulation by narrow-fraction liquid-phase hydrocarbon inert gas is based on the original equipment, and an inert gas inlet (3) is connected to the outlet pipeline of the circulation pump (1). A one-way valve is installed on the inert gas inlet (3) pipeline to prevent hydrocarbon materials from flowing backward; there is also a flow control valve to adjust the amount of inert gas entering the cycle. The specification of the inert gas inlet (3) can be determined by the designer according to the capability of the equipment. The original equipment includes circulating pump (1), raw material inlet (2), feed heat exchanger (4), raw material heating furnace (5), reactor (6), cooler (7) and circulating buffer tank (9) . The liquid outlet of the circulation buffer tank (9) is connected to the inlet of the circulation pump (1). The gas outlet (8) of the circulating buffer tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com