Fabricating method for turning large rudder pintle of fuel ship in 300, 000 tons

A processing method and rudder stock technology, which is applied in the field of processing 300,000-ton oil tanker large rudder stock, and achieves significant technical effects, low processing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

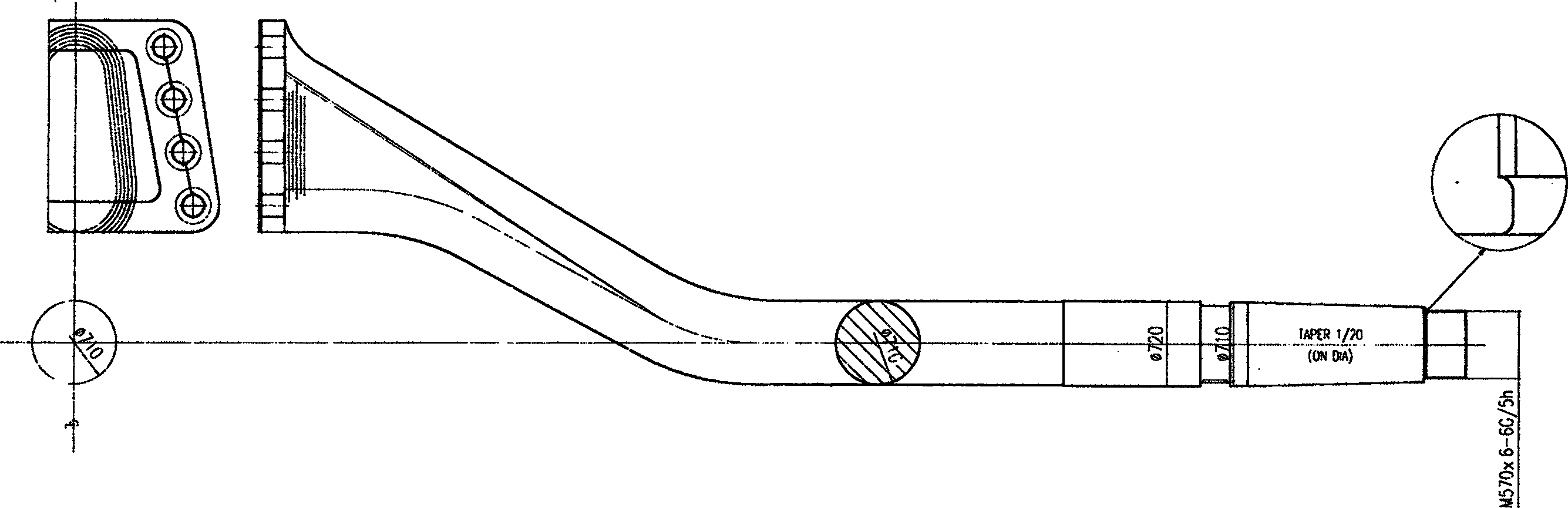

[0023] Such as figure 1 As shown, the large rudder stock used by the 300,000-ton tanker is a special type of part, and the existing heavy-duty horizontal lathes do not have this processing capability.

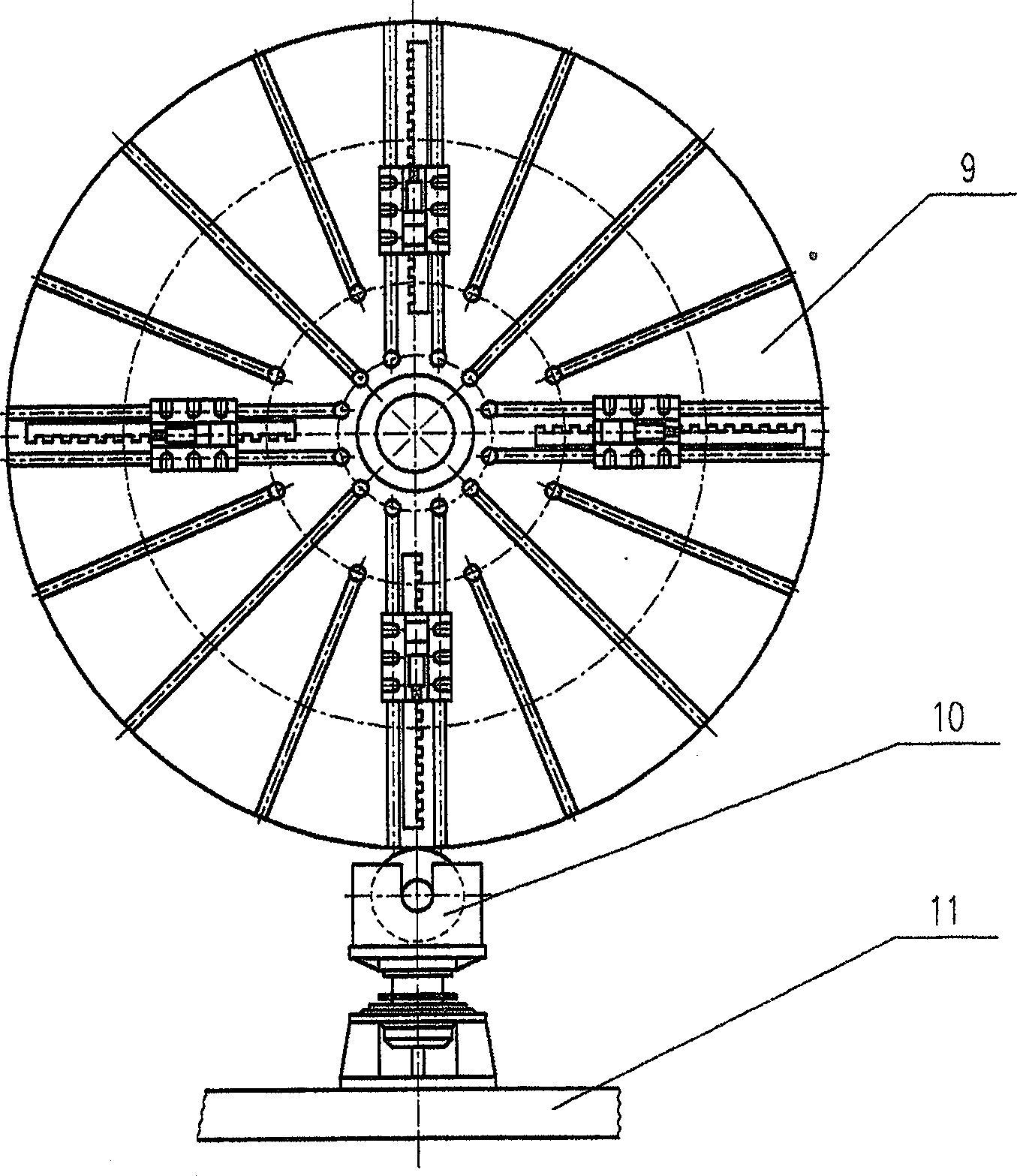

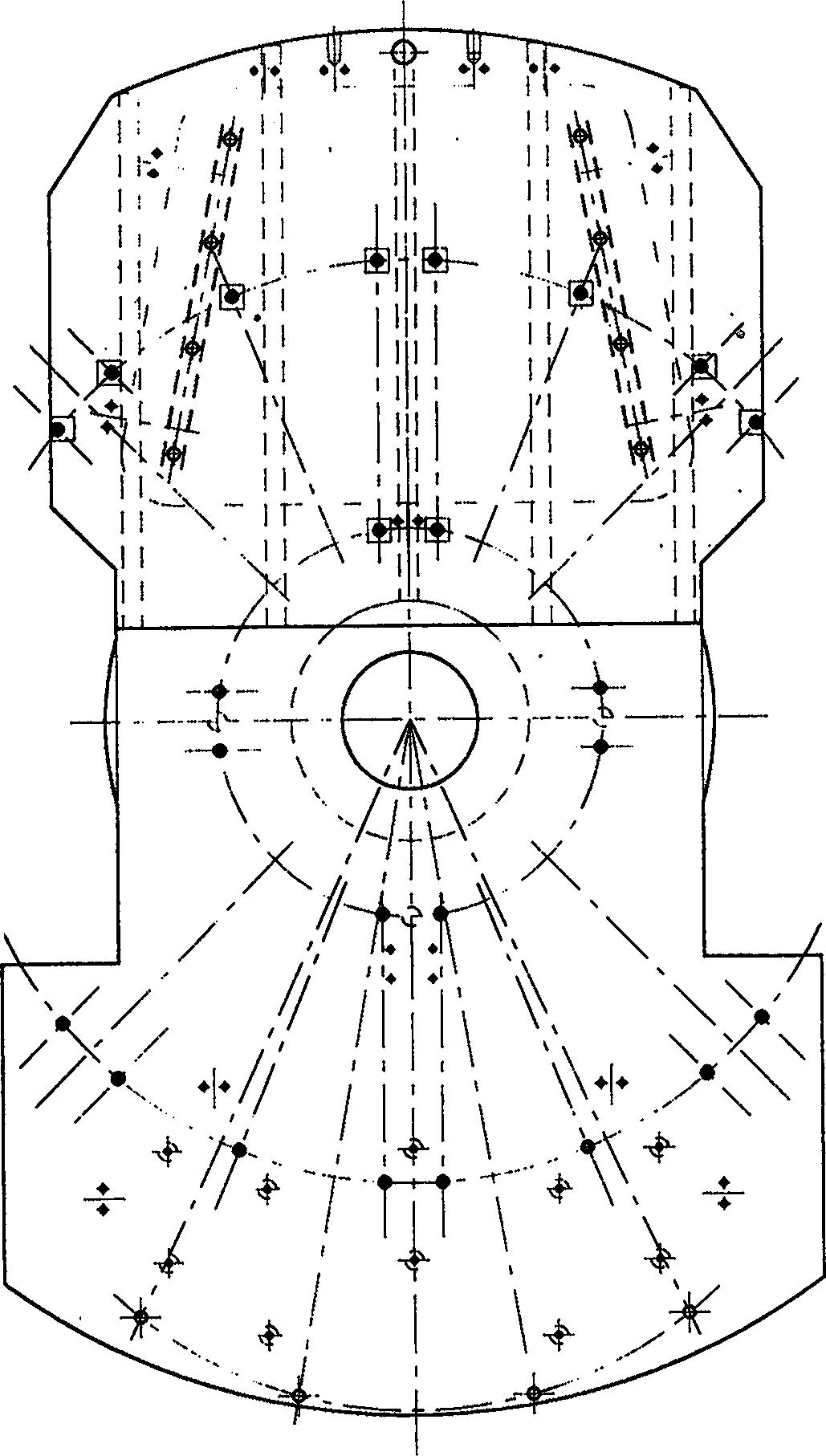

[0024] The present invention adopts a bull head lathe used for processing the rotary cylinder to turn the rod portion of the rudder stock. The faceplate of the bull head lathe has a diameter of ¢4.2m and a maximum load of 80 tons, which can be adapted to a processing range of ¢5.88×12m after enlargement and transformation.

[0025] The specific method is as follows:

[0026] Firstly, the rudder stock is roughly machined on the floor boring machine, and the rudder stock is milled into a polygonal shape with a universal square milling head to ensure the machining allowance of the bar. After rough machining, the weight of the rudder stock is 50-60 tons; This is to reduce the weight of the rudder stock when it is clamped on the bullhead lathe as much as possible, and leave a marg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com