Method for producing highly chlorinated methanes

A technology of highly hypochlorinated methane and hypochlorinated methane, applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., can solve the problems of chlorine loss, insufficient research on raw material hindering factors, and large-scale recovery equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

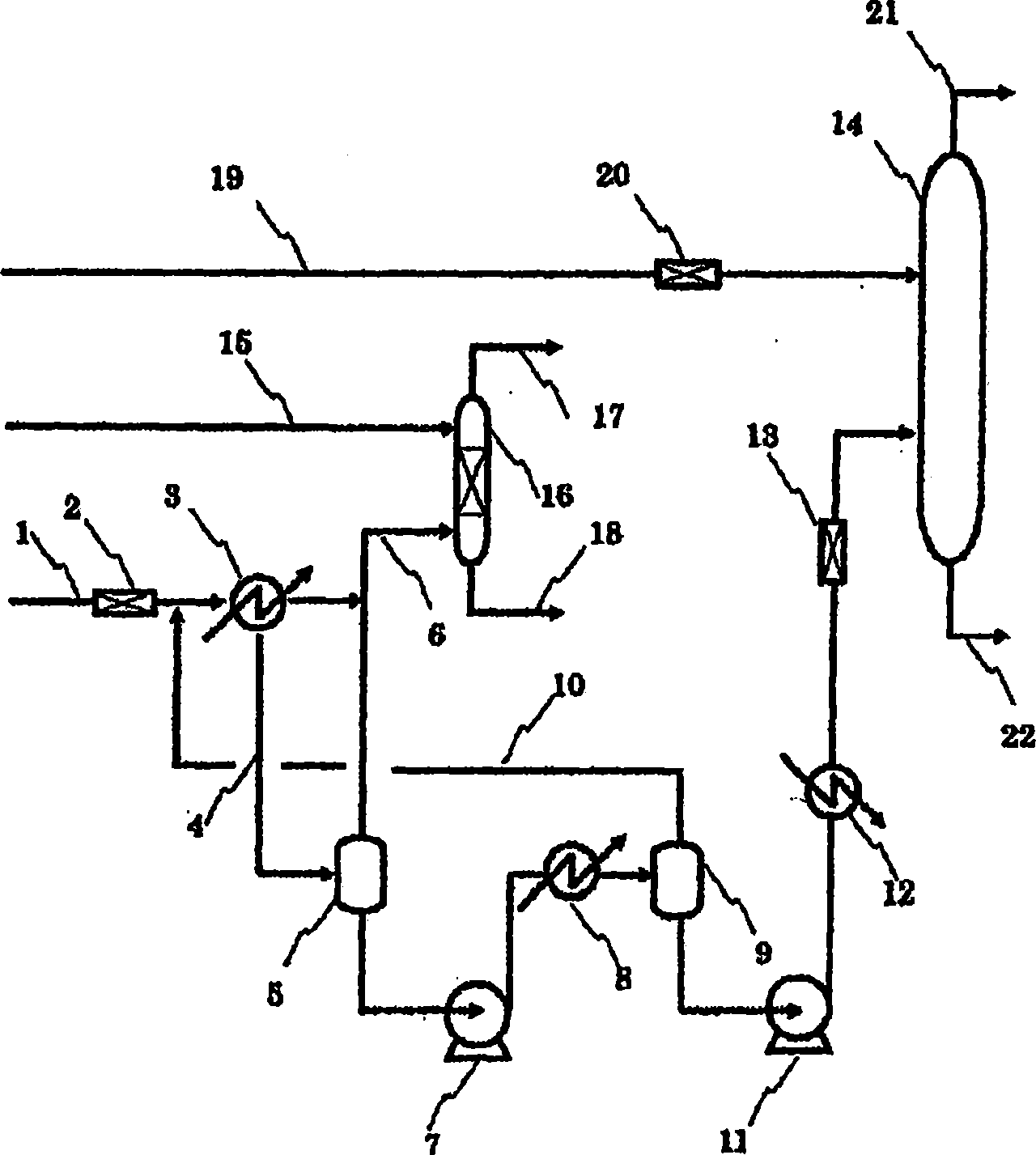

[0042] through as figure 1 The shown method for producing hyperchlorinated methanes using the chlorine supply method of the present invention produces hyperchlorinated methanes. Chloromethane and dichloromethane were supplied to the reactor at 9.8kg / h, chlorine containing 55 mass ppm oxygen was supplied at 9.2kg / h, and in the presence of a radical initiator, the The reaction was carried out in the liquid phase. The amount of iron brought in by this raw material was 2 mass ppm, and the moisture content was 14 mass ppm. In the reactor after the reaction started, the reaction was carried out at a stable temperature and pressure. In addition, in order to purify oxygen in chlorine to 55 mass ppm, the loss amount of chlorine was 1.5 mass %.

Embodiment 2

[0044] The same method as in Example 1 was followed except that the concentration of oxygen in the supplied chlorine was 40 mass ppm, the iron carried in from the raw material was 4 mass ppm, and the water was 18 mass ppm. In the reactor after the reaction started, the reaction was carried out at a stable temperature and pressure. In addition, in order to purify oxygen in chlorine to 40 mass ppm, the loss amount of chlorine was 2.5 mass %.

Embodiment 3

[0046] The same method as in Example 1 was followed except that the concentration of oxygen in the supplied chlorine was 20 mass ppm, the iron carried in from the raw material was 4 mass ppm, and the water content was 18 mass ppm. In the reactor after the reaction started, the reaction was carried out at a stable temperature and pressure. In addition, in order to purify the oxygen contained in chlorine to 20 mass ppm, the loss amount of chlorine was 3 mass %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com