Stepless automatic gear shifting in gear drive

A technology of automatic transmission and gear transmission, applied in the direction of gear transmission, transmission, transmission control, etc., can solve the problems of high cost and time-consuming processing of hydraulic parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

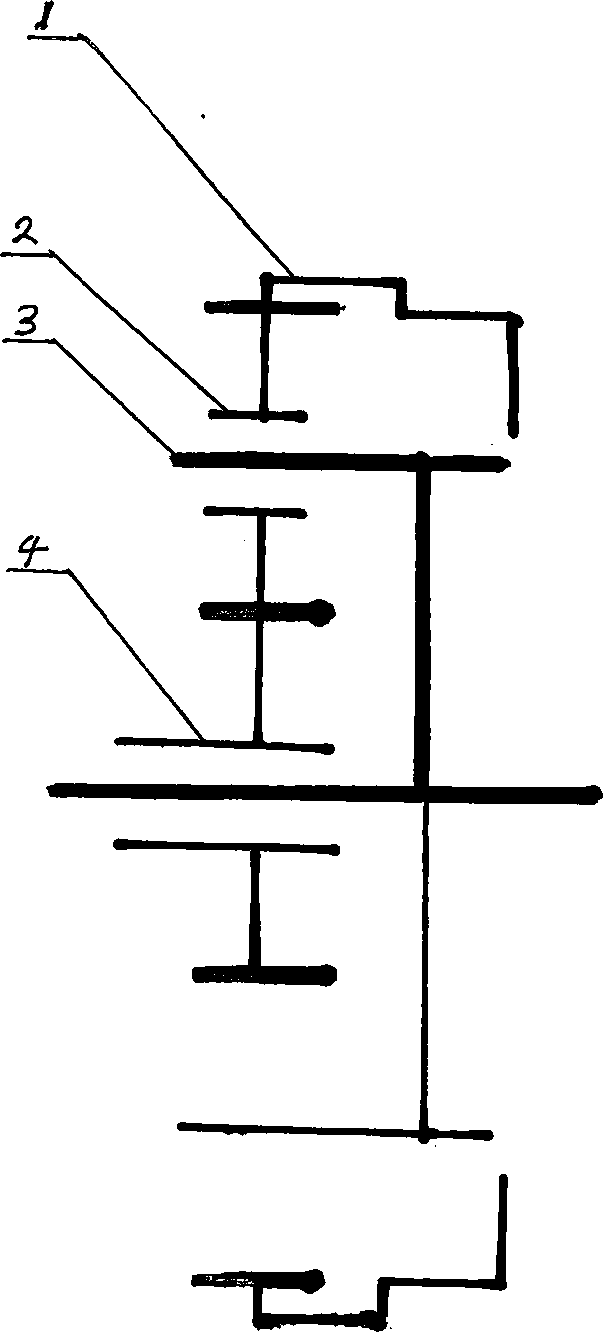

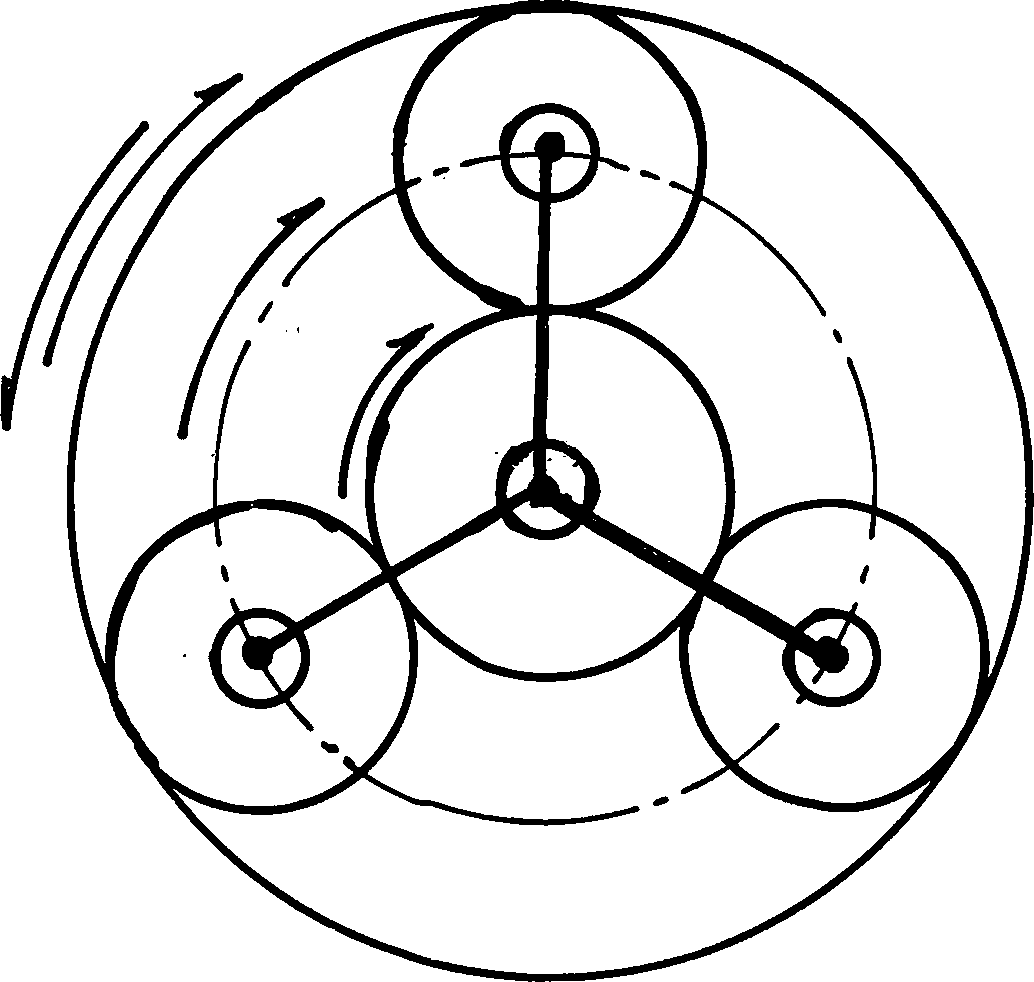

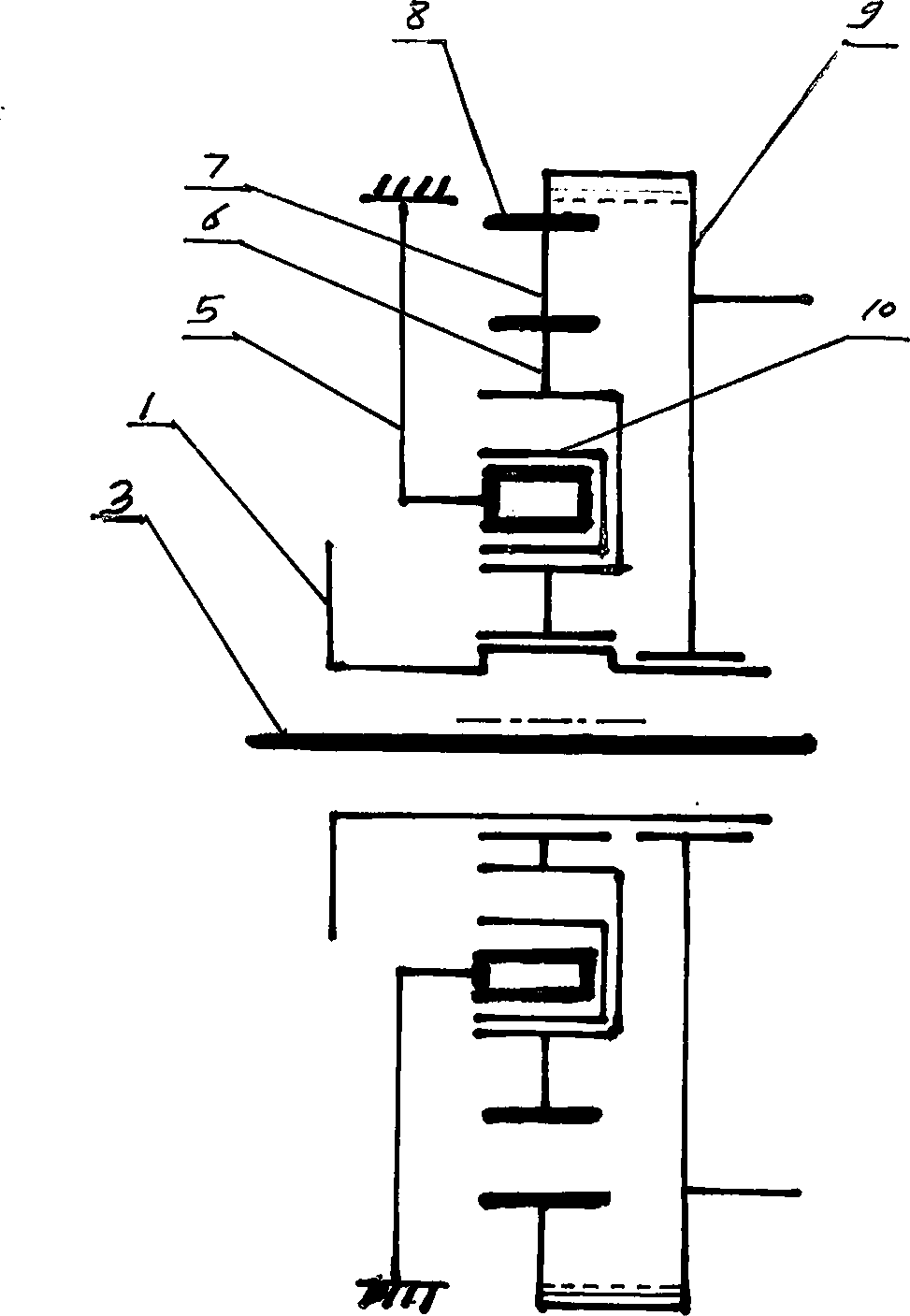

[0047] The present invention comprises two planetary gear sets and self-locking mechanism, starting clutch, and the first planetary gear set is made up of sun gear 4, planetary gear 2, internal gear 1 and planetary gear carrier 3, and the second planetary gear set is made of sun gear 44, Planetary gear 42, internal gear 41 and planetary gear carrier 3 constitute. The sun gear is connected with the planetary gears, and the planetary gear carrier of the two planetary gear sets is a whole. The self-locking mechanism is installed between the two planetary gear sets. The self-locking mechanism is composed of a swinging central gear 6, a free planetary gear 7, a swinging internal gear 8 and a connecting piece 9, a fixed pin 5 and a fixed pin sliding bearing 10, the swinging central gear 6 meshes with the free planetary gear 7, and the free planetary The gear 7 is meshed with the swing internal gear 8. There are a central round hole and a plurality of symmetrical round holes on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com