Ring type heat exchanging system

A heat exchange device and loop technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve problems such as low yield rate of finished products, unfavorable return of working liquid, and obstruction of liquid return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

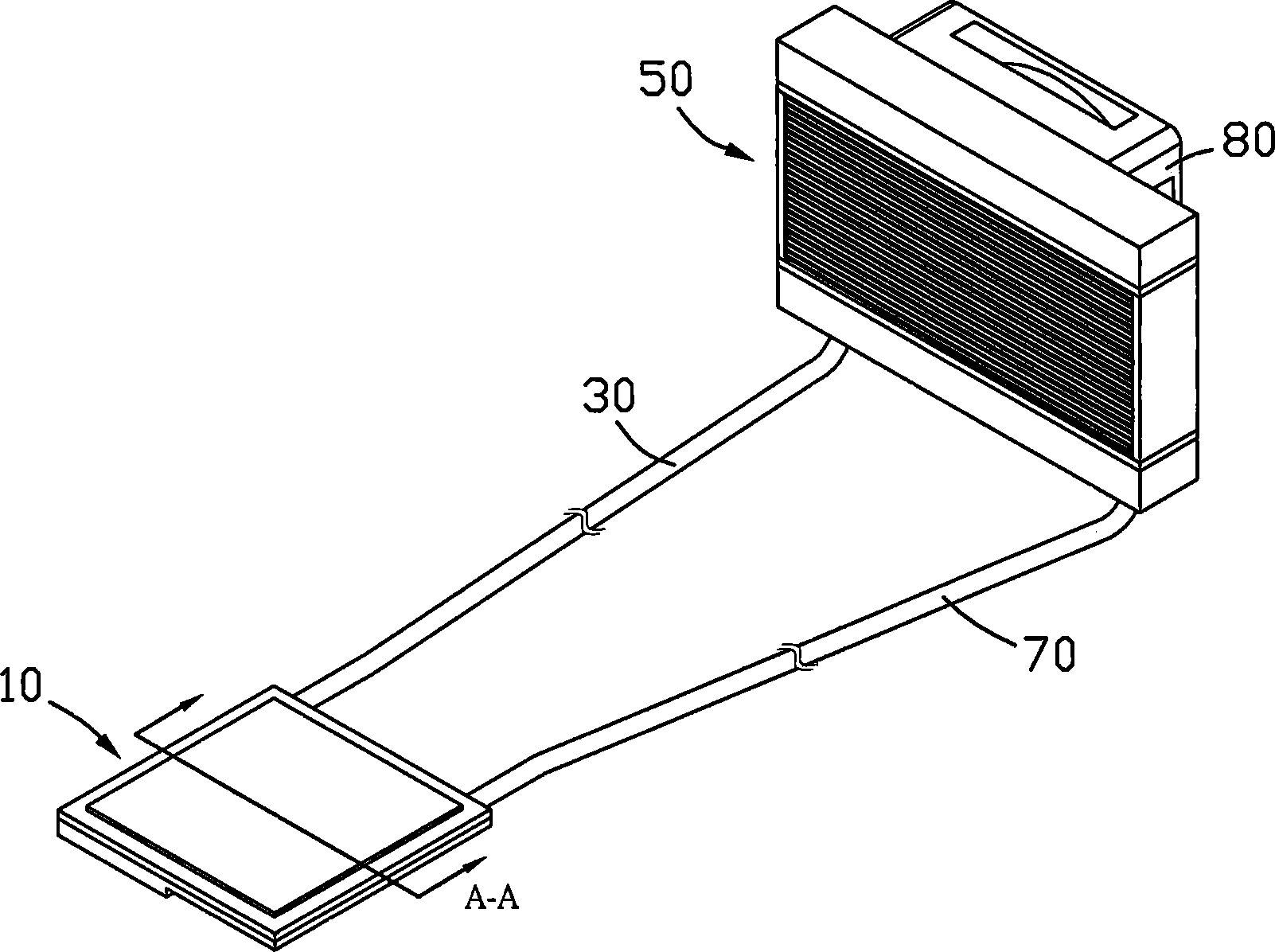

[0036] figure 2 It is a three-dimensional schematic diagram of the appearance of the first embodiment of the loop heat exchange device of the present invention, including an evaporation part 10 , a steam conduit 30 , a condensation part 50 and a return conduit 70 .

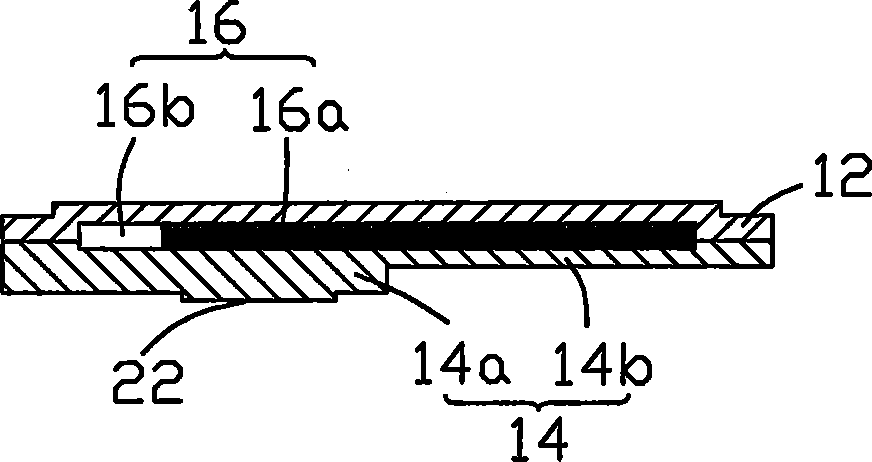

[0037] image 3 for figure 2 The evaporator 10 in the figure is a sectional view viewed along the A-A section, the evaporator 10 includes an upper cover plate 12 and a lower cover plate 14, and the upper cover plate 12 and the lower cover plate 14 form a sealed flat cavity 16, in which There are multiple microfluidic channel capillary structures composed of several layers of tightly arranged metal meshes, and the capillary structure divides the cavity space into a liquid phase microfluidic channel area 16a and a low flow resistance steam channel area 16b. The upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com