Bush for a chuck and method of its manufacture

An intermediate shaft and chuck technology, applied in the direction of chucks, manufacturing tools, couplings, etc., can solve the problem of high cost and achieve the effects of low processing cost, small clamping force loss and high production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

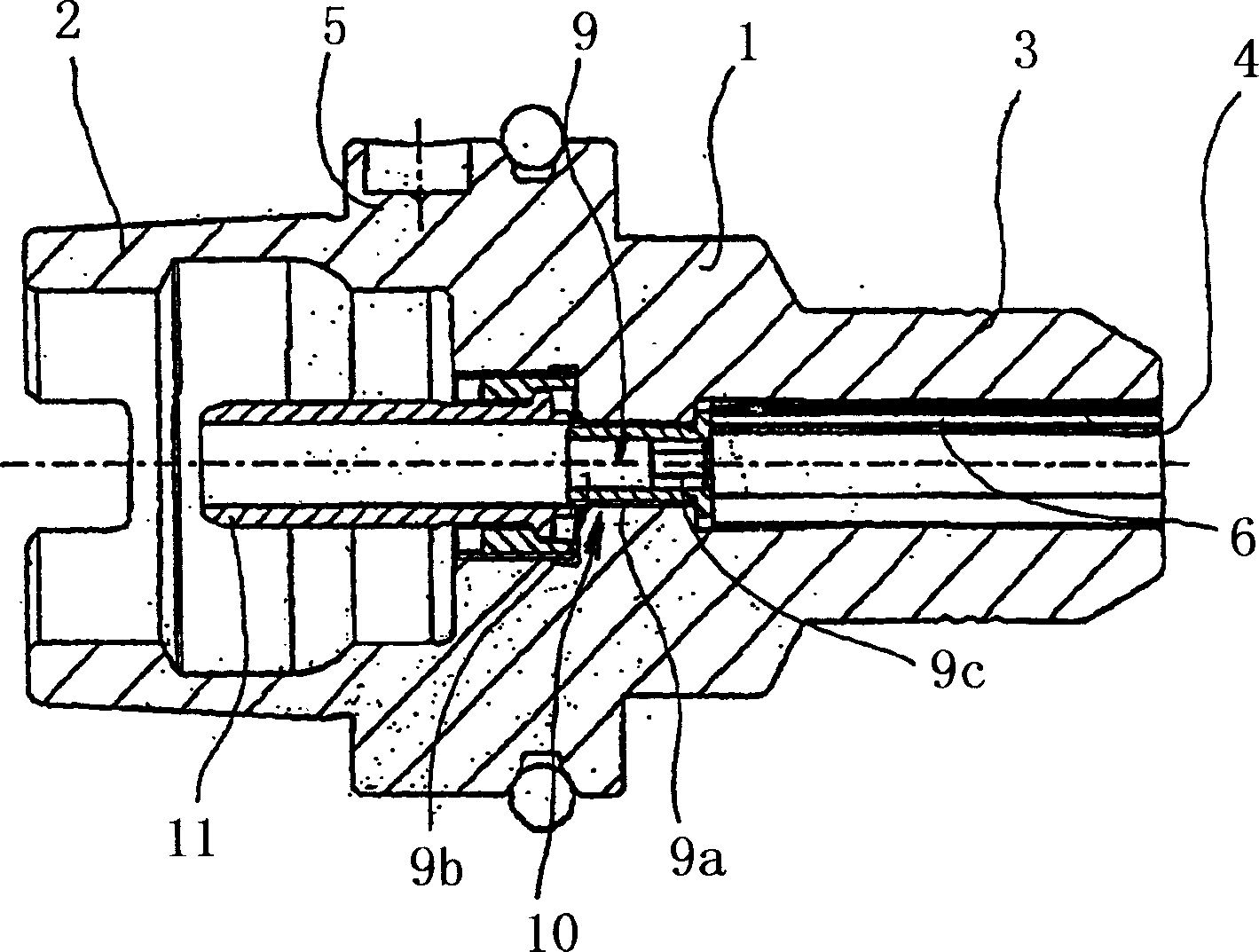

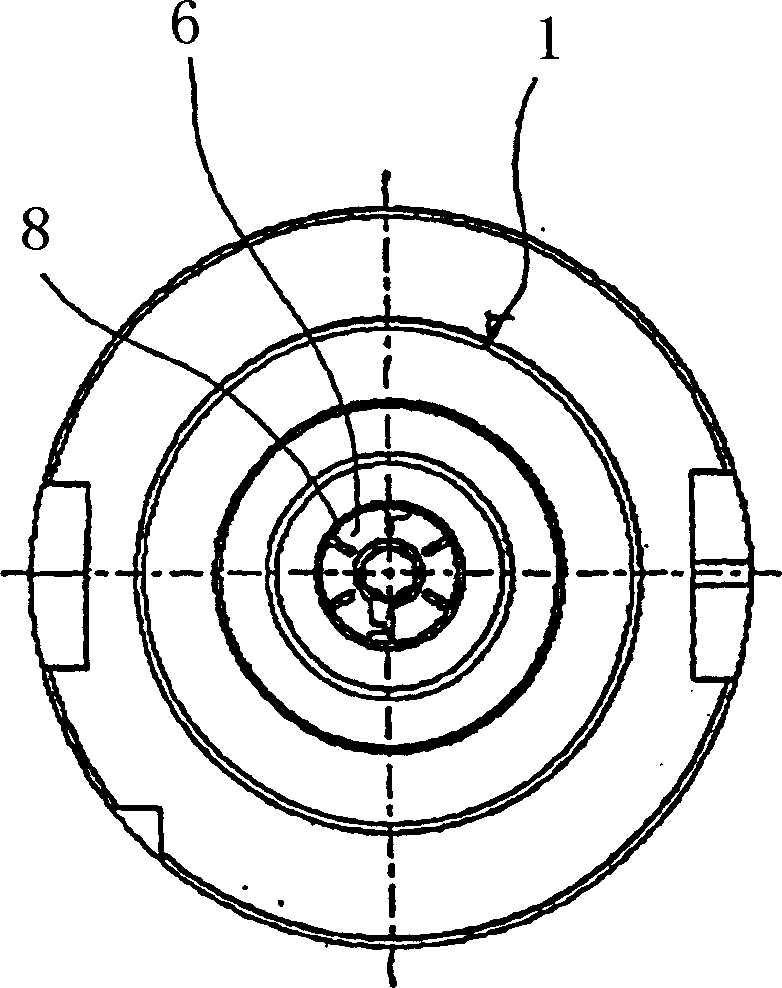

[0020] exist figure 1 and figure 2 In , an embodiment of the chuck according to the invention is shown in longitudinal section and in front view. This chuck has a chuck body 1 made of rigid material with a connection cone 2 in a known manner at one end region of the chuck body 1 for the rotary drive work of the clamping to the machine tool on the spindle. On the other end of the chuck body 1 there is provided a connecting shaft 3 with a central socket 4 into which a cylindrical shaft of a tool such as a drill or cutter can be pushed, and in the connecting cone Between 2 and the connecting shaft 4 there is a central portion 5 of increased diameter.

[0021] The chuck shown is in the form of a heat shrink chuck. Alternatively, however, an embodiment in the form of an expansion chuck is also possible, which then has an expansion clamping mechanism in a known manner in the region of the connecting shaft 3 .

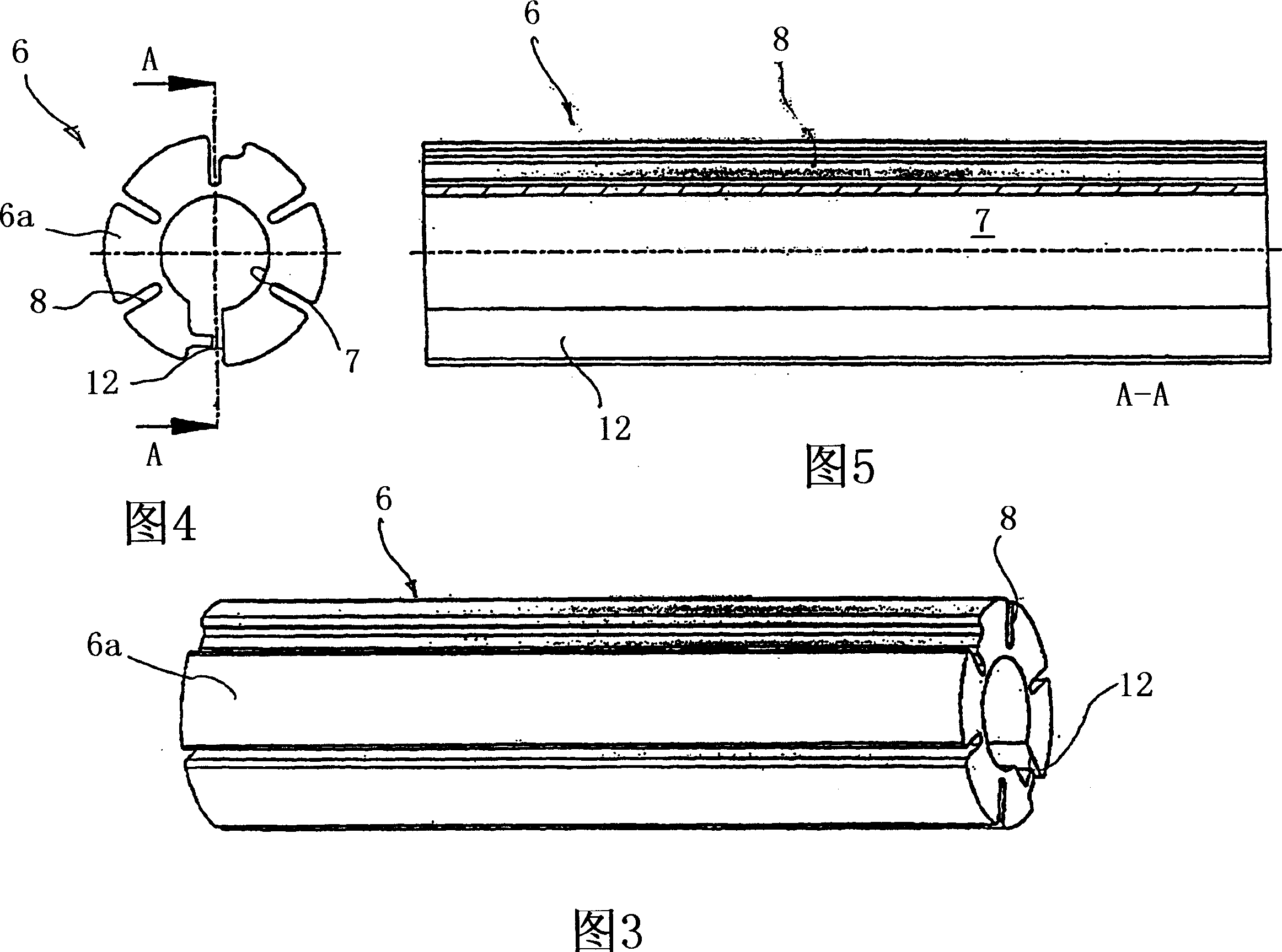

[0022] Also in order to be able to use the chuck 1 to clamp the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Maximum width | aaaaa | aaaaa |

| Maximum width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com