Directly crosslinked blue dye preparation process

A preparation process, blue color technology, applied in the direction of complex metal compounds of azo dyes, azo dyes, organic dyes, etc., can solve the problems of poor coloring, waste of resources, insufficient heat resistance, etc., to achieve good coloring, not easy Good effect of fading and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Direct cross-linking dyes, also known as reactive direct dyes, can be used in conjunction with reactive color fixing agents, which is different from general direct dyes, thereby improving their wet fastness and rubbing fastness.

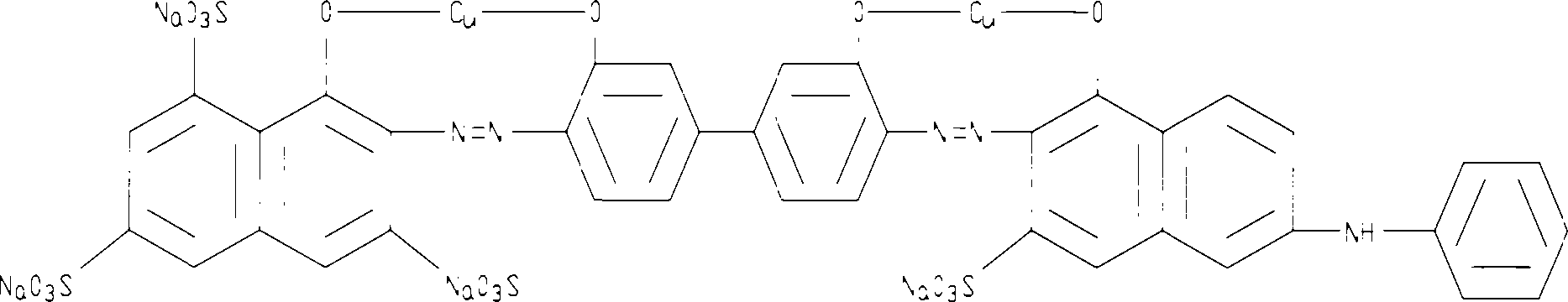

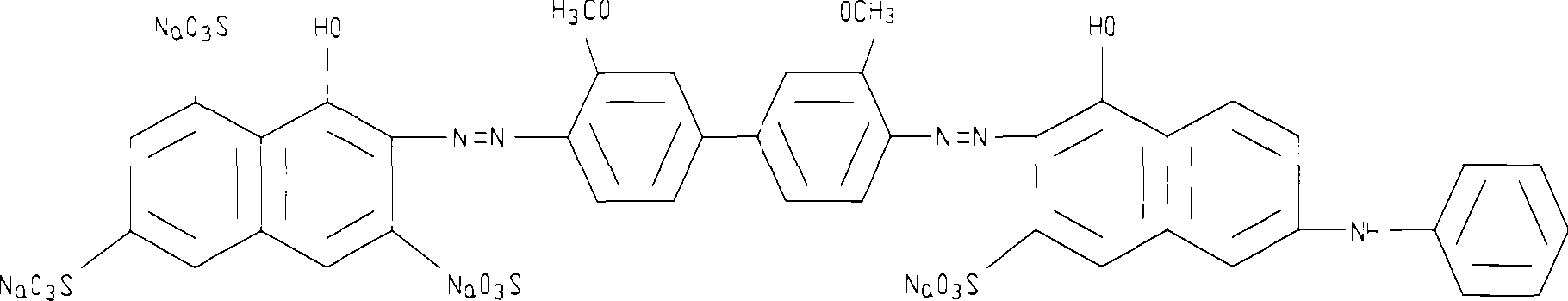

[0021] A kind of preparation technology of directly cross-linked blue dye comprises following reaction steps:

[0022] ①. Diazo reaction: Mix 1.0 moles of 3,3, dimethoxybenzidine with 75 moles of water, heat the mixture to 70°C and stir to make it fully mixed, add 4.9 moles to a concentration of 30% hydrochloric acid, stir the solution for 7 hours, then add ice to cool it to 4°C, and slowly add 2.03 moles of 30% sodium nitrite solution dropwise on the liquid surface after 3 hours, the reaction temperature is 11°C, and then react 2 hours until the end point to produce 3,3, dimethoxybenzidine double nitrogen salt;

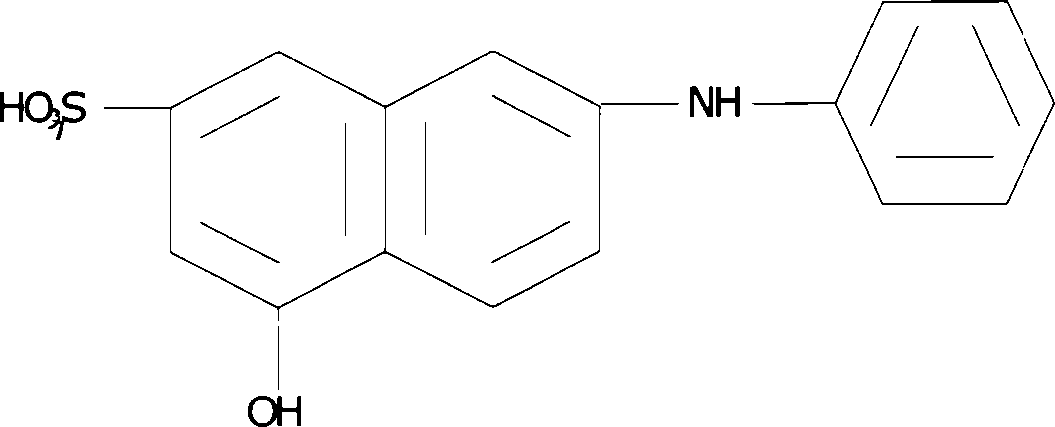

[0023] ②, a coupling reaction: dissolve 1.1 moles of 1-hydroxynaphthalene-3,6,8 trisulfonic acid into 305 moles of water, add hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com