Light-emitting device with an electrode arrangement

A light-emitting element and electrode arrangement technology, which is applied to electrical elements, electroluminescent light sources, electric light sources, etc., can solve problems such as increasing production costs, and achieve the effects of reducing manufacturing costs, simplifying electrical contacts, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

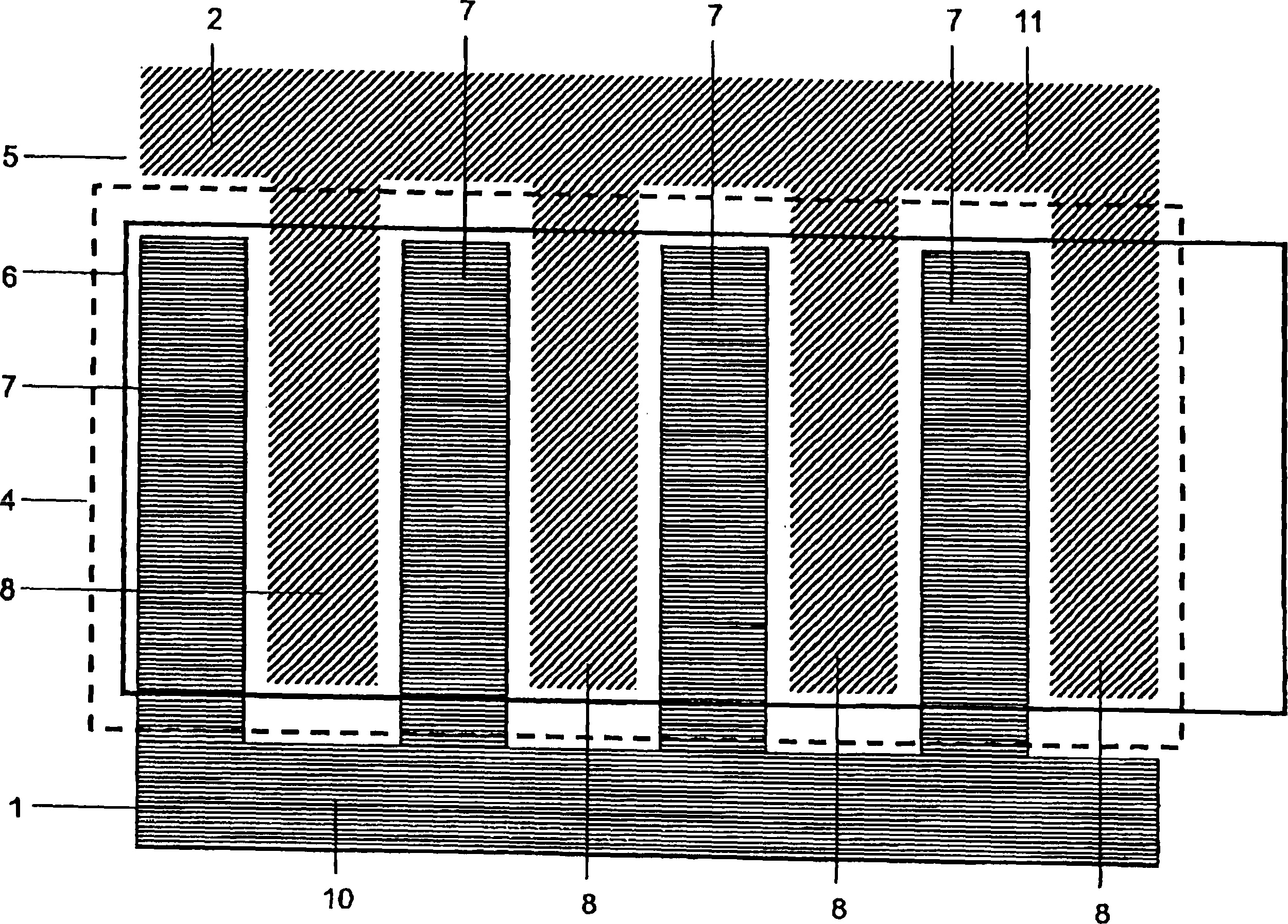

[0039] figure 1 is a schematic diagram of the electrodes of a light-emitting element through which the light-emitting organic region is excited by applying a voltage. The electrode comprises two planar partial electrodes 1 , 2 which are formed in layers adjacent to each other. Above the two partial electrodes 1 , 2 a light emitting region 4 is formed as a layer which has a plurality of organic layers which are themselves distributed across the component surface 5 and which emit light when a voltage is applied. In the illustrated embodiment, the light-emitting region 4 comprises two organic regions with different structures, each of which emits light in a specific color. A planar counter-electrode 6 is arranged above the light-emitting region 4 .

[0040] By applying a voltage to the electrodes including the partial electrodes 1, 2 and the counter electrode 6, the voltage is applied to the plurality of organic regions in the light emitting region 4, thereby emitting light. Two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com