Method for installing an elevator

A technology for elevators and elevator shafts, applied in the field of elevators, can solve problems such as the expansion of car boxes, and achieve the effects of reducing installation time, saving installation time, and reducing installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

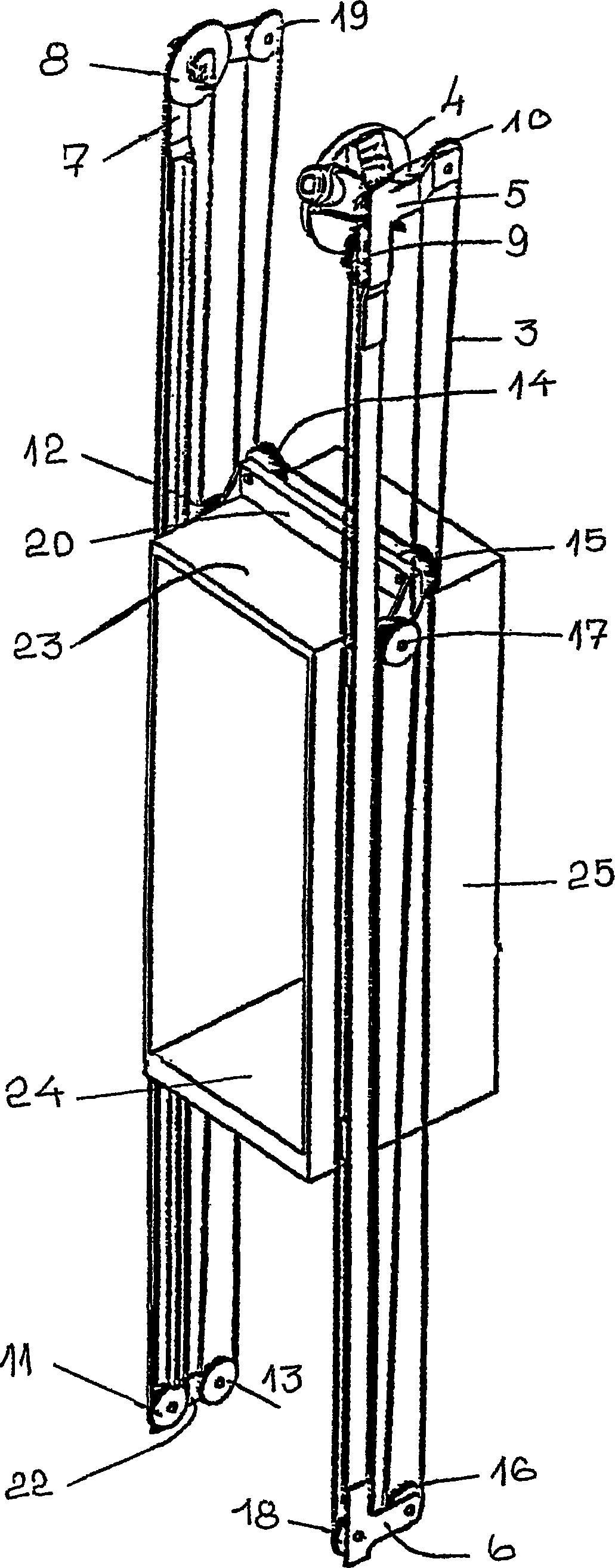

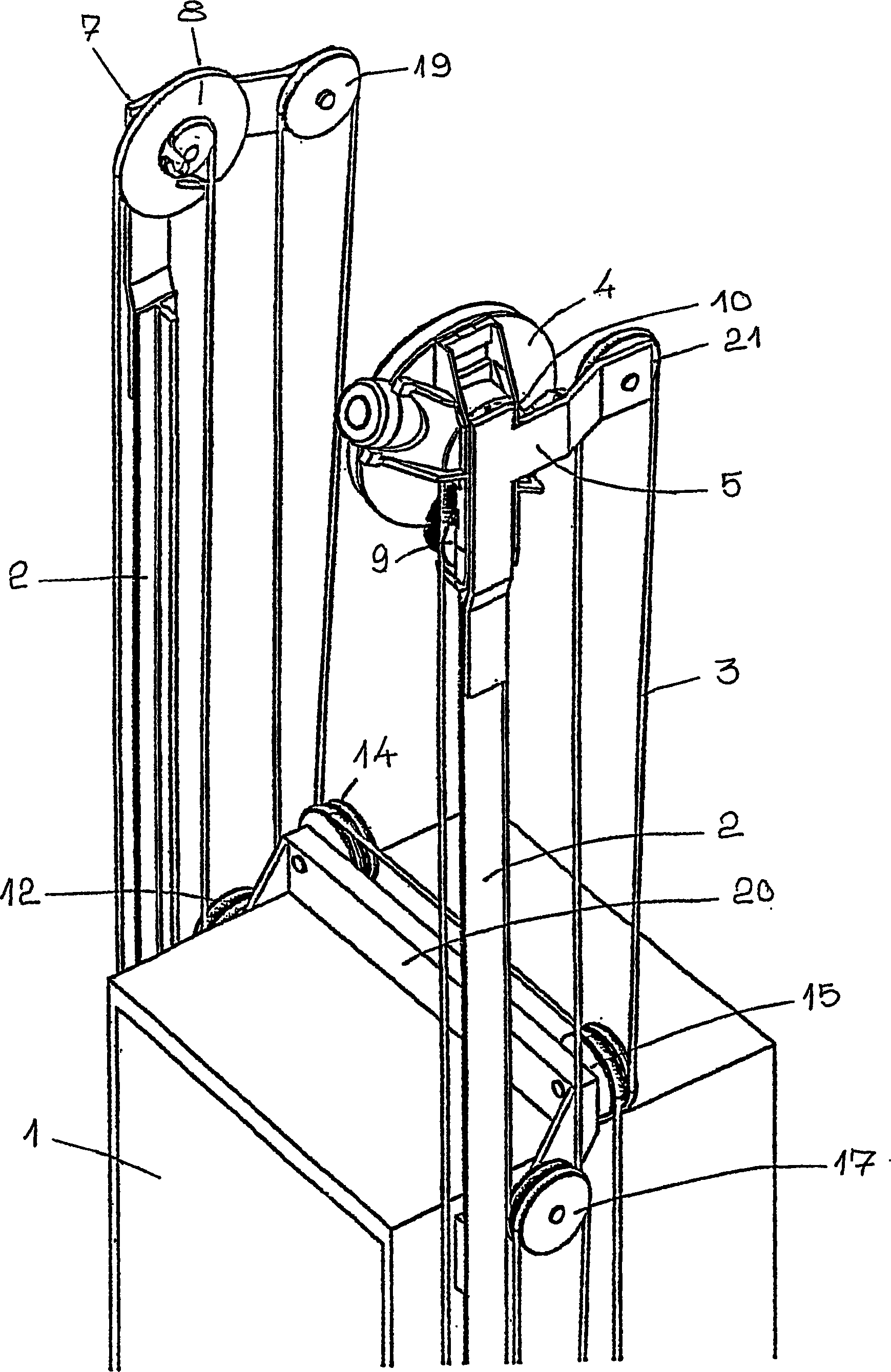

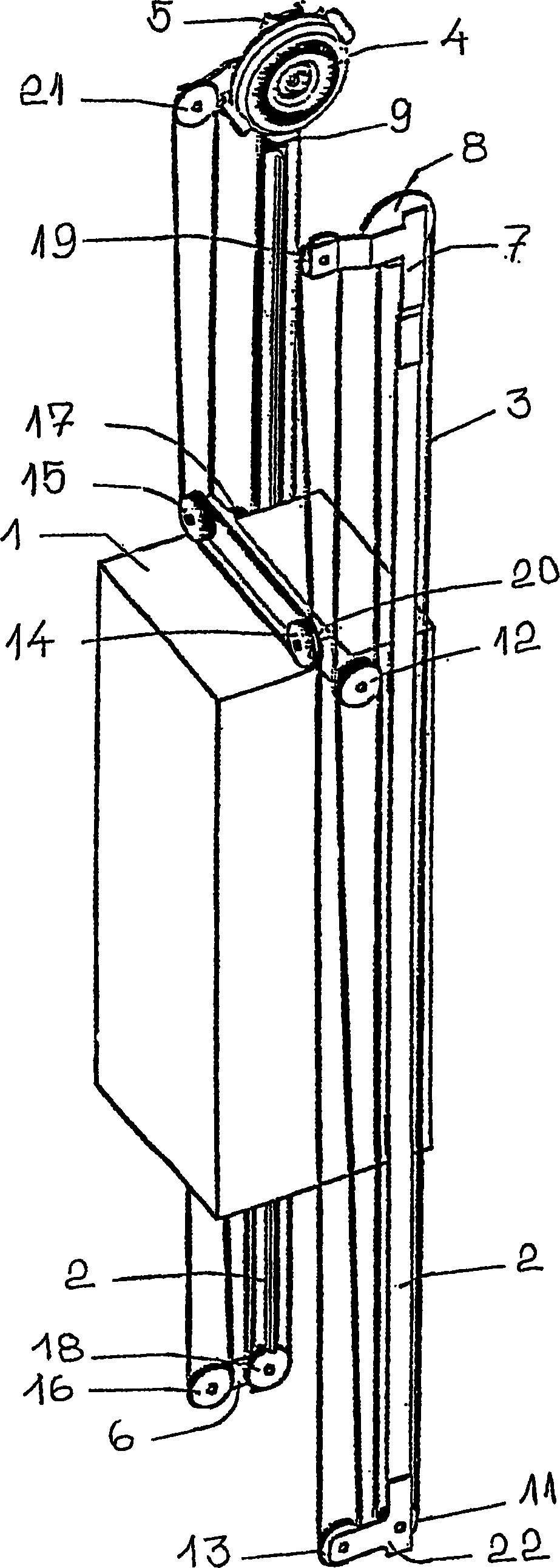

[0056] figure 1 , 2 and 3 represent the elevator structure according to the invention. The elevator is preferably an elevator without a machine room and the drive machine is arranged in the elevator shaft. The elevator shown in the figures is a traction sheave elevator without counterweight and with the machine on top, wherein the elevator car 1 moves along guide rails 2 . exist figure 1 , 2 and 3, the hoisting rope is extended in the following manner: one end of the hoisting rope is fixed on a wheel of small diameter contained in the compensating mechanism that functions as a compensating device 8, said wheel being fixedly mounted on a second large diameter wheel, the second wheel is included in the compensating mechanism 8 . Via a support element 7 fixed immovably on an elevator guide rail 2 , the compensating mechanism 8 as compensating device has been fixedly mounted on the elevator shaft. From the small diameter wheel of the compensating mechanism 8, the hoisting ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com