Reciprocating internal-combustion engine with direct fuel injection by means of an injector arranged on the intake side

一种内燃机、往复式的技术,应用在内燃活塞发动机、燃烧发动机、机器/发动机等方向,能够解决增加壁热损失、刺耳燃烧噪音等问题,达到减少不发火、减少烟尘的形成、提高燃烧稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

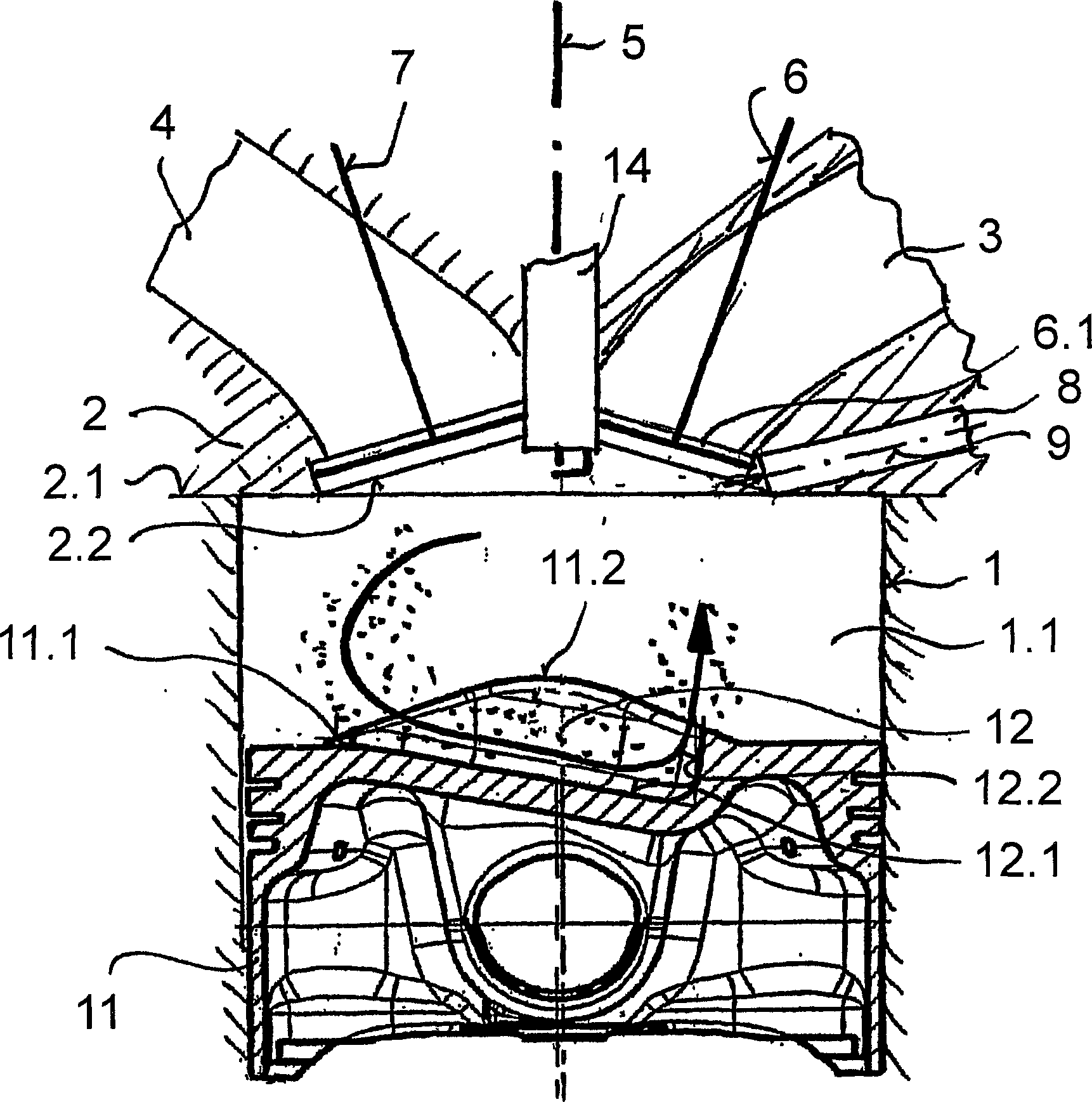

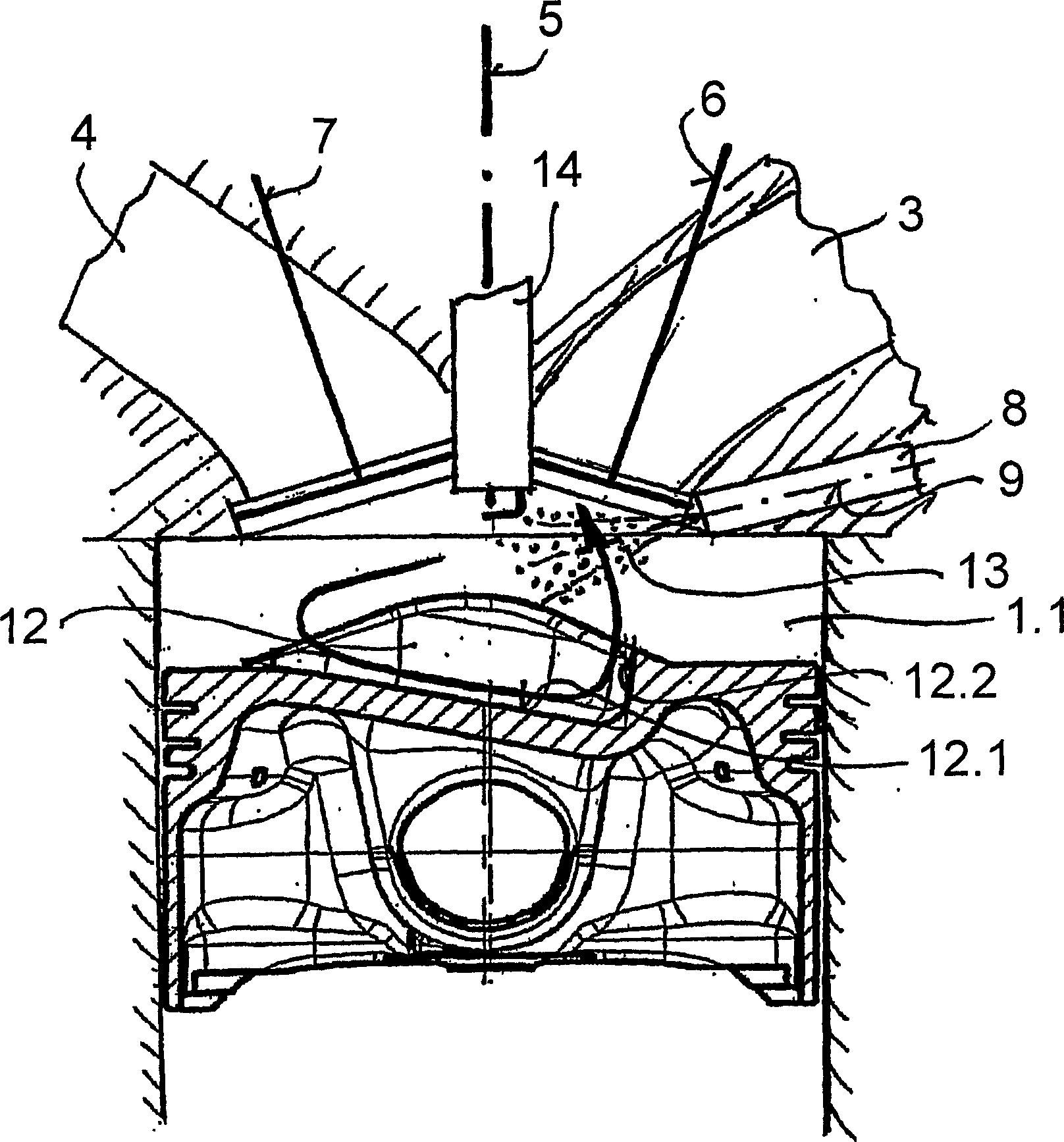

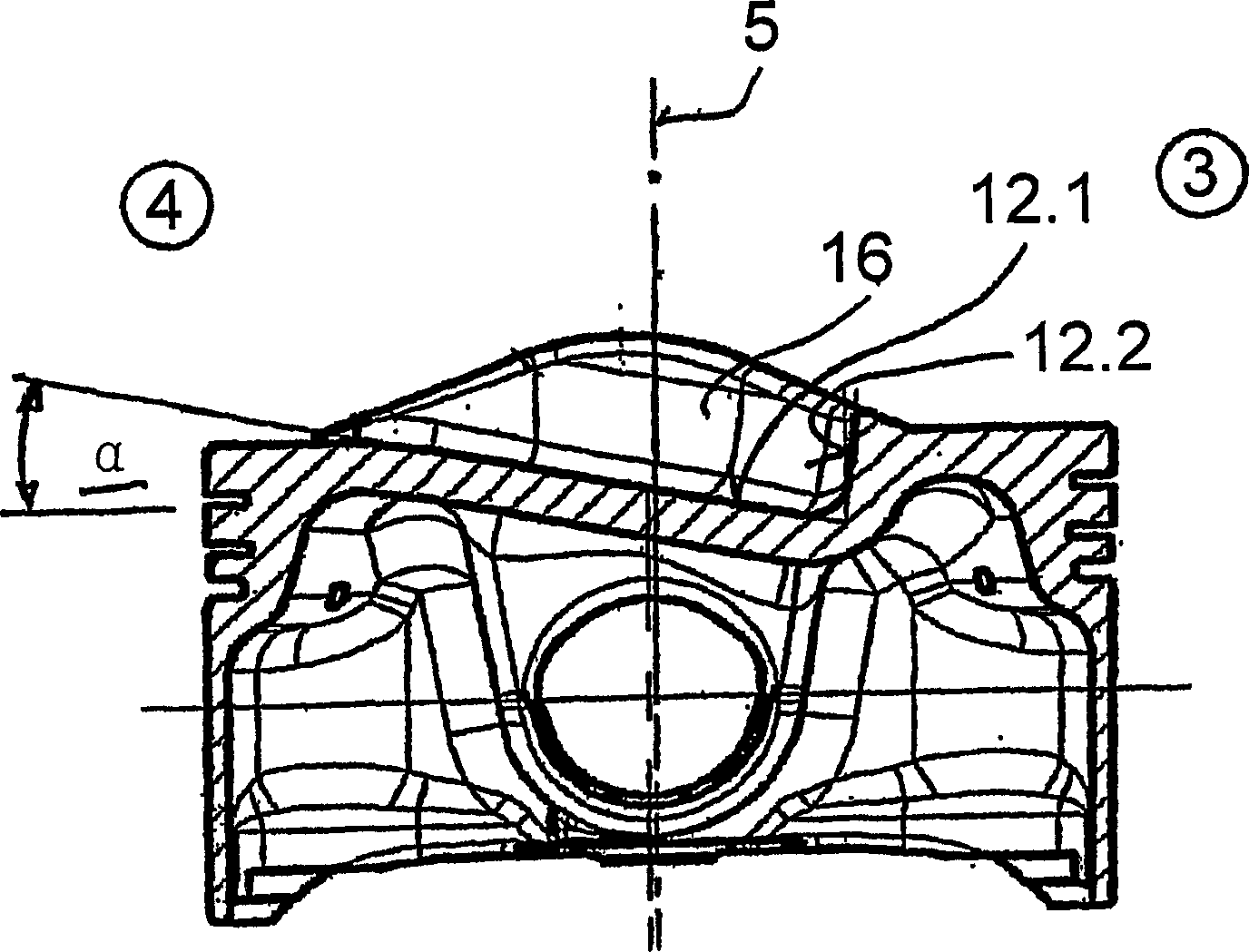

[0025] figure 1 The illustrated cylinder 1 of the reciprocating internal combustion engine is provided with a cylinder head 2 having two obliquely extending intake openings 3 and two exhaust openings 4 arranged substantially mirror-symmetrically to the intake openings. From figure 1 As can be seen in a vertical section, both the intake port 3 and the exhaust port 4 are located in the cylinder head 2 so that they open into the cylinder chamber 1.1 at an angle of less than 45° (measured relative to the cylinder head plane 2.1). The intake port 3 can be opened and closed by the corresponding intake valve 6 , and the exhaust port 4 can be opened and closed by the corresponding exhaust valve 7 .

[0026] The fuel nozzles 8 are arranged in the cylinder head 2 in the region of the intake valves 6 and may be part of a high-pressure direct fuel injection system of common rail technology. In the exemplary embodiment shown here with two intake ports 3 , the fuel nozzle 8 is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com