One-step Chinese medicine spray-drying and granulating process and equipment

A technology of drying and traditional Chinese medicine, which is applied in the direction of making medicines into special physical or ingestible devices. It can solve the problems of long time in the concentration stage, many equipments, and small tower diameters that are prone to sticking to the wall, so as to prevent oxidation and The growth of microorganisms, high economic and social benefits, and the effect of optimizing drying and granulation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

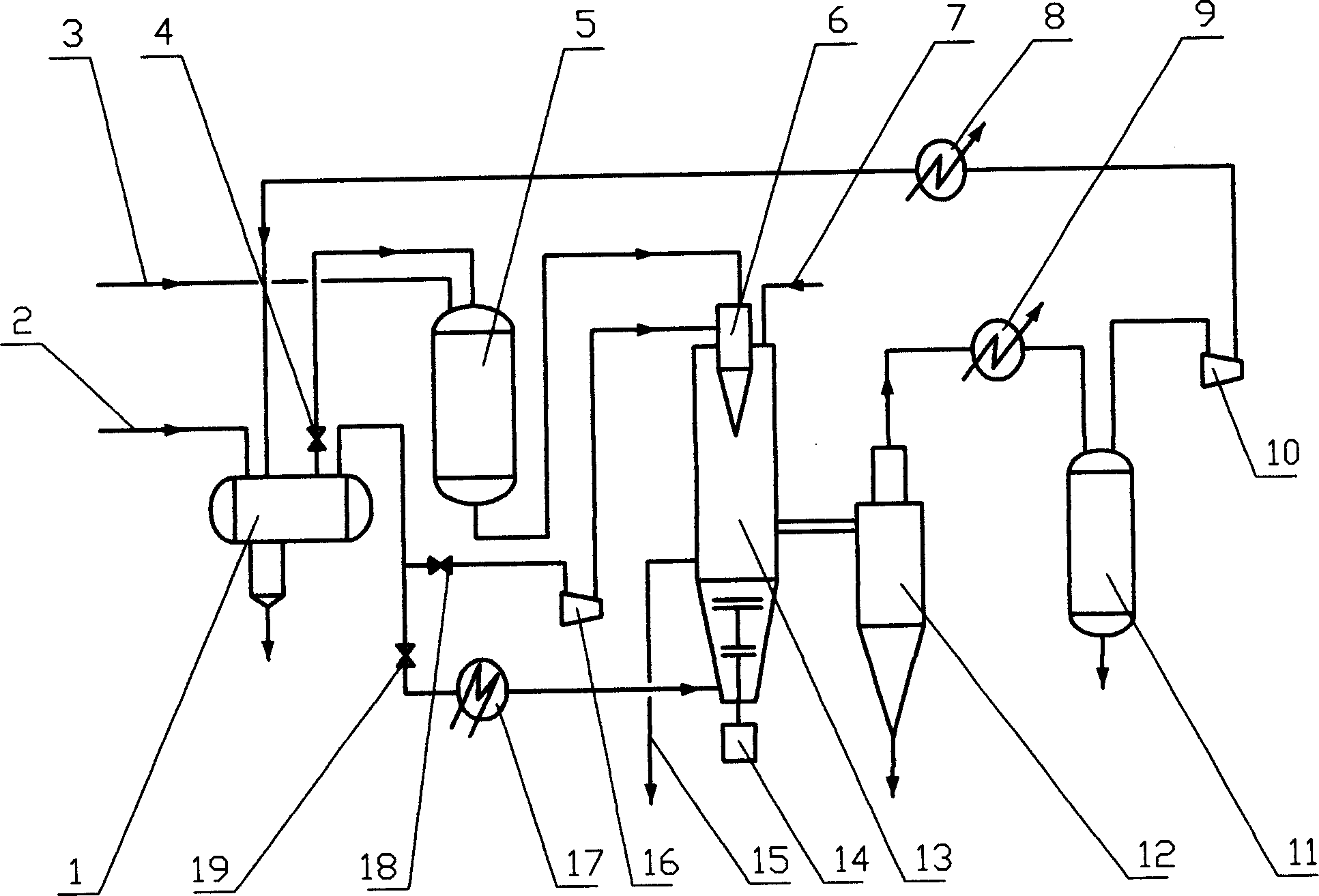

[0020] refer to figure 1 , the equipment includes a drying tower [13], a chemical liquid storage tank [5], a circulating gas water separation tank [1], a chemical liquid storage tank [5] has a chemical liquid inlet [3], and a nozzle on the top of the drying tower [13] [6] and the feeding inlet [7] of the auxiliary material powder, the middle part has the material outlet [15] and the tail gas outlet, the bottom has the agitator [14], and there is an air inlet [2] in the circulating gas water separation tank [1]. ], used to replenish nitrogen, one of the outlets is connected to the nitrogen inlet of the liquid storage tank [5] through the valve [4], the liquid exit of the liquid storage tank [5] is connected to the liquid entrance of the nozzle [6], and the circulating gas The other outlet of the water separation tank [1] is connected to the air inlet of the nozzle [6] through the valve [18], the supercharger [16], and the circulating gas water separation tank [1] also has an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com